Not exactly. While both Xylan® and Teflon® coatings use fluoropolymer chemistry—most commonly PTFE (Polytetrafluoroethylene)—they differ in formulation, purpose, and branding.

How They Compare

- Teflon® is a well-known brand originally developed by DuPont (now Chemours) that features pure PTFE or similar fluoropolymers. It’s widely recognized for its use in non-stick cookware but is also used in specialized industrial applications.

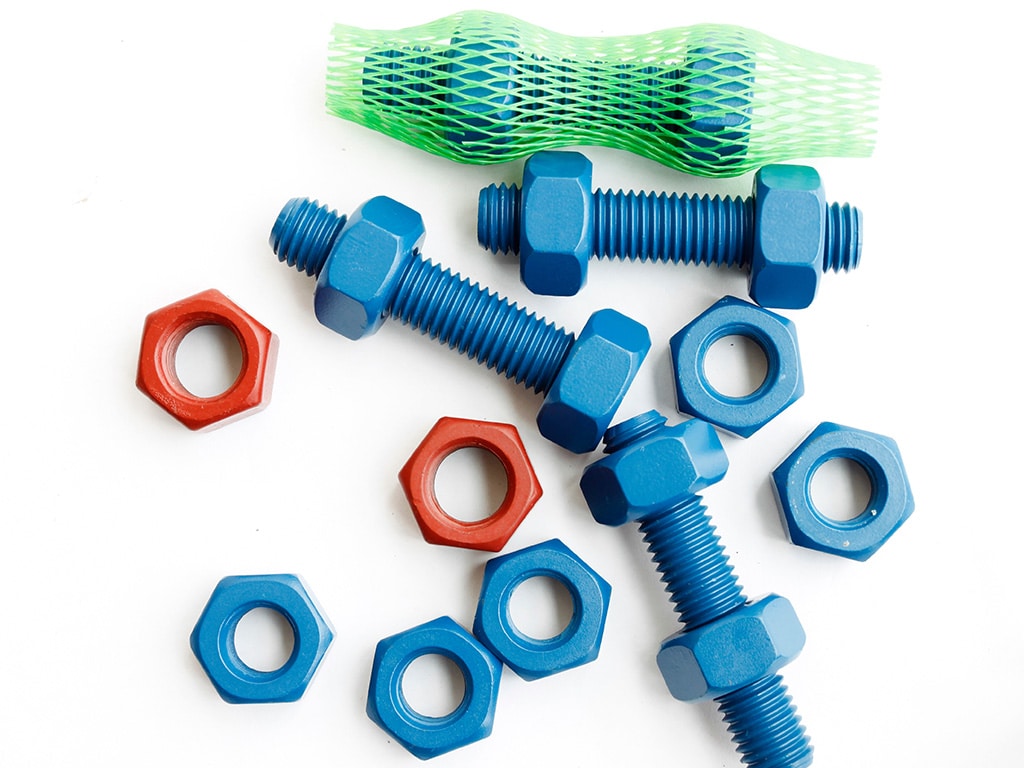

- Xylan®, made by Whitford (now part of PPG), refers to a line of high-performance coatings that blend PTFE with binders, resins, and pigments to create a more versatile solution for challenging environments.

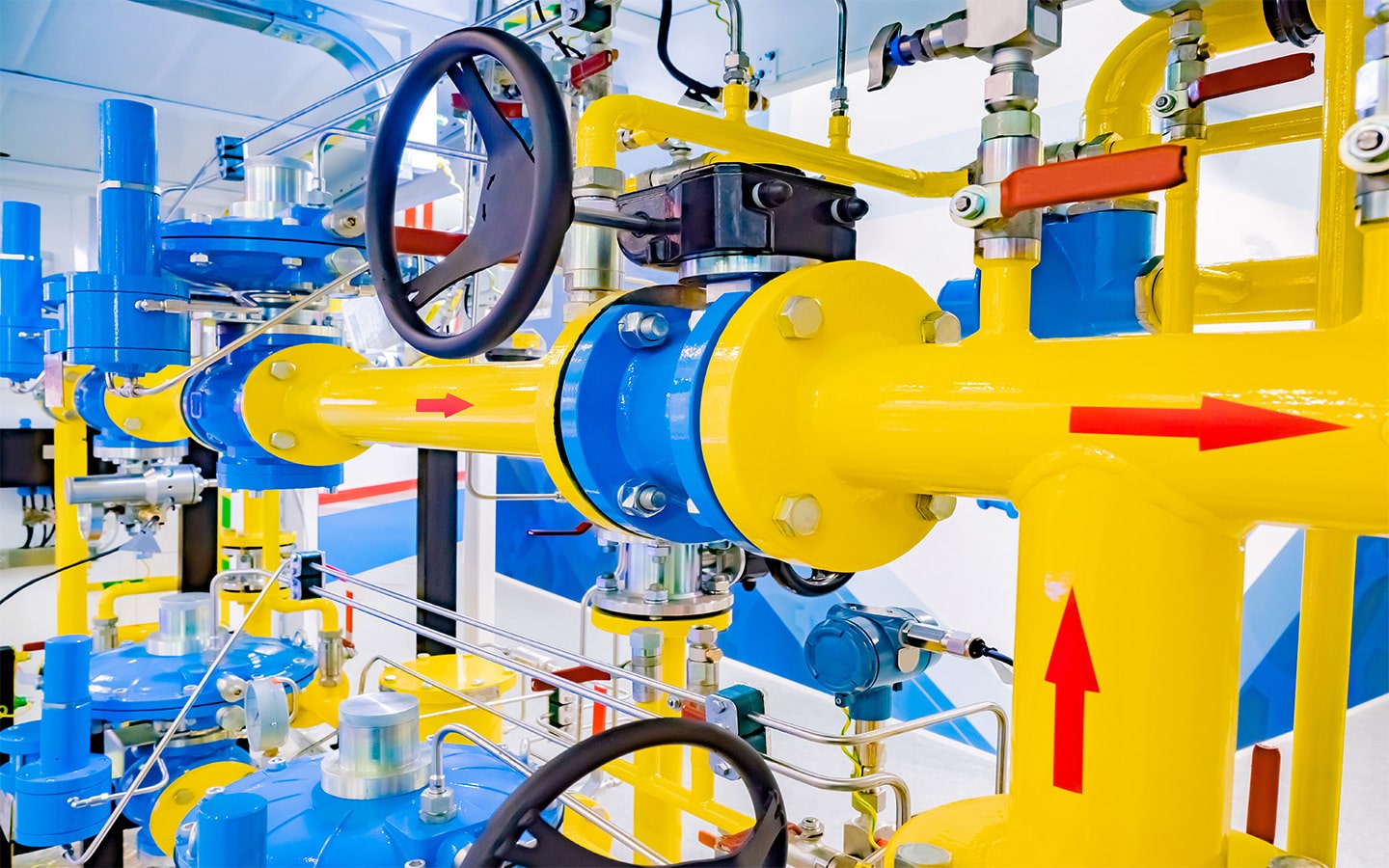

- Application Focus: Teflon® is often used where pure non-stick or chemical resistance is needed. Xylan® excels in heavy-duty industrial and food-processing applications, especially where wear resistance, corrosion protection, or dry lubrication is critical.

In summary: Teflon® is a pure fluoropolymer product line, while Xylan® coatings are engineered systems that incorporate fluoropolymers into multi-functional coating blends for demanding environments.