How Gullon Hybrid Coating Works

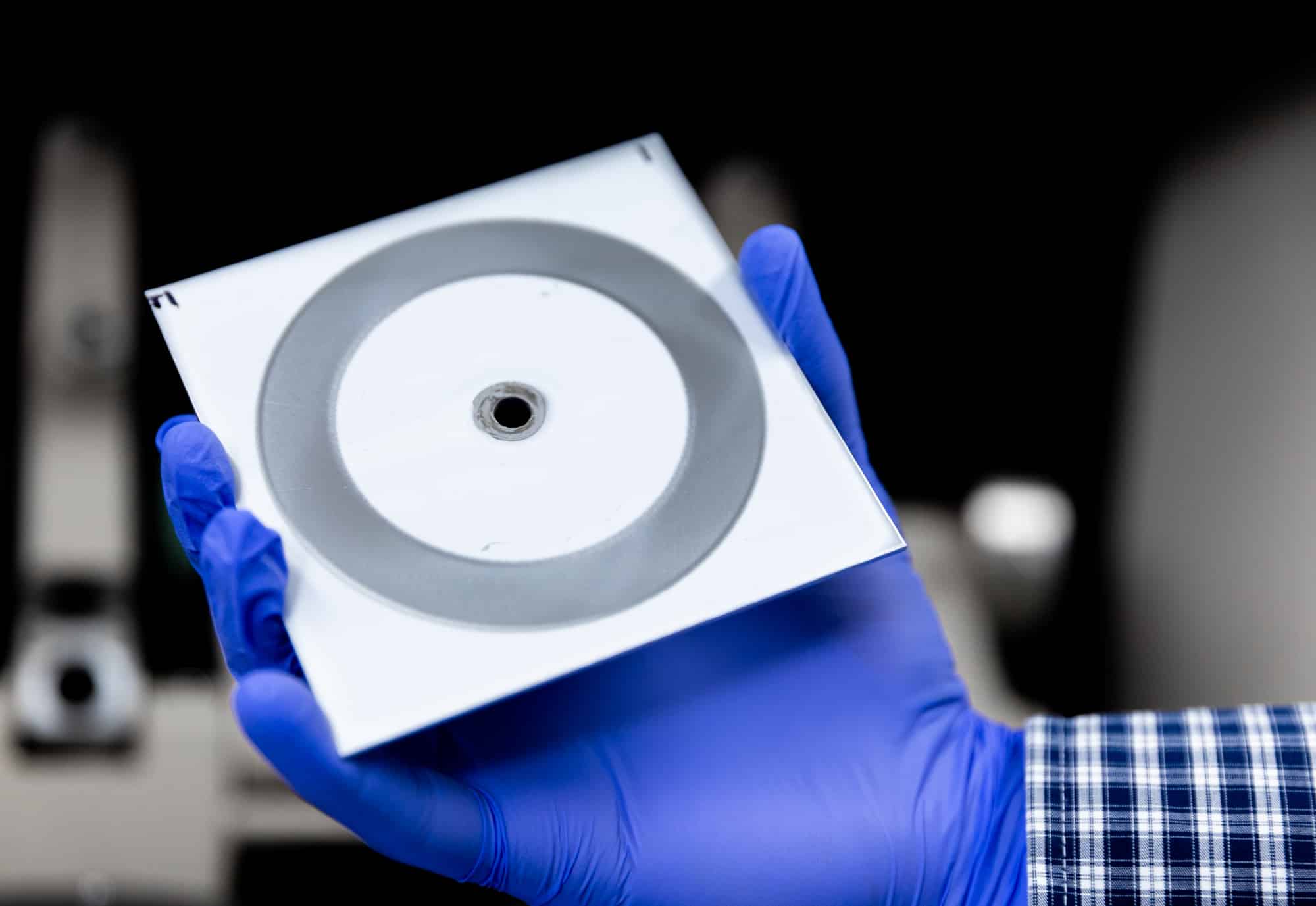

Gullon combines two surface technologies—a nodular Thin Dense Chrome (TDC®) base and a cured solid-film lubricant—to create a single, bonded coating system that performs under extreme wear, load, and environmental stress.

Unlike conventional coatings that rely on a single material to provide all performance properties, Gullon separates functions between its layers. The TDC layer delivers compressive strength, hardness, and corrosion resistance, while the top solid-film layer reduces friction, prevents galling, and improves dry running capability. Each layer is applied in a controlled, thin deposit (typically 0.00035″), preserving tolerances and enabling use on complex geometries or porous components.

The result is a duplex coating architecture engineered to outperform standalone chrome or solid-lubricant systems, especially in applications where traditional lubrication is impractical or failure-prone.

Gullon Surface Architecture and Bonding

At the core of Gullon’s performance is its nodular TDC foundation: a dense, microstructured chrome layer with a hardness rating up to 78 Rc. Unlike standard hard chrome, which relies on microcracks for lubricant retention, TDC forms a uniform nodular texture that enhances bonding and resists chipping or delamination.

This structure provides a high-integrity anchor surface for the second layer: a thermoset solid-film lubricant selected for the application. Once applied, the lubricant is bonded and cured over the TDC base, forming a chemically resistant top layer that enhances lubricity and further protects the substrate from mechanical and chemical stress.

Because both layers are applied at low thicknesses and low temperatures, Gullon coatings maintain part geometry and are safe for use on sensitive alloys or porous metals, such as powder-injection-molded (PIM) stainless steel.

Choosing Your Solid-Film Lubricants

Gullon’s performance is largely defined by the solid-film lubricant selected for the top layer. This material is chosen for the specific use case, factoring in frictional load, operating temperature, chemical exposure, and re-lubrication restrictions.

Armoloy engineers typically use one or more of the following:

- PTFE (Polytetrafluoroethylene): Offers extremely low friction and excellent chemical resistance in both wet and dry environments.

- MoS₂ (Molybdenum Disulfide): Excels under high loads and in vacuum or dry-running applications where oil-based lubricants cannot be used.

- Graphite: Provides consistent lubrication across wide temperature ranges and environmental conditions, especially where humidity or thermal cycling is a factor.

- Hybrid blends: For specialized needs requiring a balance of friction control, thermal stability, and anti-corrosion performance.

These lubricants are embedded in a resin matrix, then heat-cured to form a bonded, wear-resistant film. The resulting surface resists chemical degradation, prevents sticking and seizing, and functions as a dry-lubricated system across a wide range of industries.

Built for Clean, Maintenance-Limited Environments

- Dry-running conditions

- Corrosive fluids or chemical washdowns

- Extreme loads and contact pressures

- Cleanroom or sanitary regulations (medical, food, packaging)

Because the coating typically requires no reapplication, it can significantly extend the service life of components that are inaccessible or subject to strict cleanliness standards. Gullon also prevents galling, a form of adhesive wear common in stainless steel and PIM parts, making it especially valuable for metal-on-metal assemblies and motion systems.