Armoloy Coatings

What is Nodular Thin Dense Chrome?

Armoloy’s Nodular Surface Solution

The Armoloy Corporation helps global manufacturers protect their most valuable, high-precision components with a broad spectrum of engineered compositions of Thin Dense Chrome coatings.

Nodular Thin Dense Chrome (NTDC) stands as a reliable choice among Armoloy’s offerings for global manufacturers, serving as a reliable solution to reduce friction, combat wear and corrosion, enhance lubrication properties, and reinforce metal surfaces across diverse applications, ultimately extending their longevity and enhancing operational reliability.

Performance Characteristics

Nodular Thin Dense Chrome by the Numbers

- Surface hardness up to 78Rc

- 10% – 67% reduction in coefficient of friction

- Corrosion resistance tested to AMS 2438 per ASTM B-117

- Taber Wear Index (TWI) as low as 0.7

- Thermal expansion range of 2.7 – 4.6 (10 ̄6/°F)

- Density of 7.14 g/cm ̄3 at 20°C

- Typical deposit range of .0001 to .0003″ (2.54 to 7.62 µm)

- Effective deposit range of .000050” to .0001” (1.27 to 17.78 µm)

- Withstands temperatures of -400°F to 1600°F (-240°C – 870°C)

- Low processing temperature, <150° F (<65°C)

- Bond strength exceeding 125,000 PSI

- Excellent resistance to broad range of chemicals including acids, bases, and solvents

Nodular Thin Dense Chrome Highlights

- High wear resistance

- Increased surface hardness

- Low coefficient of friction

- Improved release

- Enhanced corrosion resistance

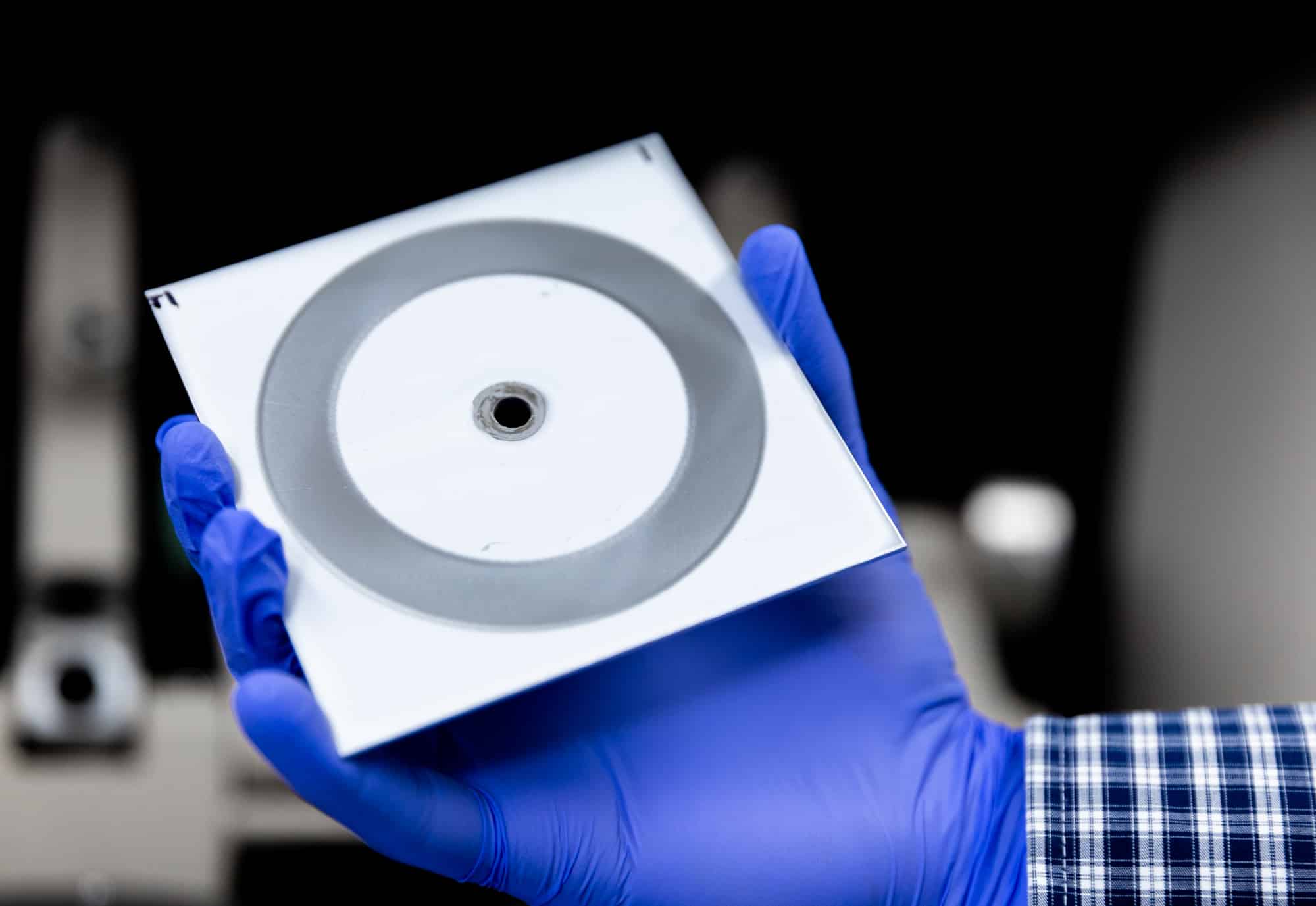

- Uniform deposit thickness even on complex geometries

- Thin, precise deposits

- Consistent, uniform matte finish

- Low processing temperature

- Broad effective temperature range

Proven applications

Applying Armoloy Thin Dense Chrome can improve the long-term performance of applications within the following industries, as well as many others:

Certifications

- Aerospace Material Specification SAE AMS2438 Plating, Chromium Thin, Hard, Dense Deposit

- Aerospace Material Specification SAE AMS2406

- Process Specification No. 180 Nodular Thin Dense Chromium (NTDC) Plating

- Aerospace Material Specification SAE AMS2460 | AMS-QQ-C-320, Chromium Plating (Electrodeposited)

- Honeywell GPS3116-1H Plating, Specialized

- Fisher FFS 2E1 Chromium Coating for Service to 1100F(593C)

- MIL—C-23422 Military Specification, Chromium Plating, Electrodeposited

- ASTM B650 Standard Specification for Electrodeposited Engineering Chromium Coatings on Ferrous Substrates

Nodular Thin Dense Chrome Features & Benefits

Absolute adhesion

Will not flake, crack, or separate from the base metal

Micronodular surface

Minimizes opposing surface contact, dramatically reduces friction, improves release characteristics

Low processing temperature <150°F

Eliminates annealing and will not distort the base metal

High wear resistance

Exceptional for sliding applications and abrasive wear

Chemical resistance

Stable in acids, alkalis, solvents and gasses

Anti-galling characteristics

Excellent resistance to adhesive wear, enhanced tolerance of low-lube

Pure metallic non-toxic chromium coating

USDA approved coating and FDA compliant, nontoxic (USP tested, REACH compliant, RoHS compliant), Bio-compatible surface

No sharp edge buildup

Minimizes dimensional change

Thin, precise deposits

Does not require post plate machining. Will not affect part tolerances or balance

Lubrication retention

Nodular surface retains wet and dry lubricants

Global reach

Armoloy-licensed applicators in North America, Europe, Africa, and Asia

Diverse industries

Widely used in aerospace, nuclear, oil & gas, and food processing & packaging

The Science Behind Nodular Thin Dense Chrome

How it Works

Coatings are a fundamental part of surface engineering for improving the mechanical properties and operational performance of components. Thin Dense Chrome’s micronodular surface texture is a notable instance of how advanced coatings can be engineered to meet the stringent demands of high-precision industries. This hard, dense, yet ultra-thin chromium coating not only improves and protects metal surfaces but also ensures that part tolerances remain unaffected, a crucial factor for components with tight specifications.

Our proprietary application process, which deposits nodular thin dense chrome in a controlled chemical bath, results in a uniform chromium layer that can be as thin as .000050″ (1.27 µm) without sacrificing performance. This coating provides a range of surface engineering benefits, including significant reductions in wear, friction, and corrosion. The nodular finish enhances lubrication retention, which is essential in high-performance systems, and minimizes surface contact, thereby reducing the risk of metal fatigue and failure.

Have you heard of Electrolizing TDC?

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.