Service Highlights

Innovation Center

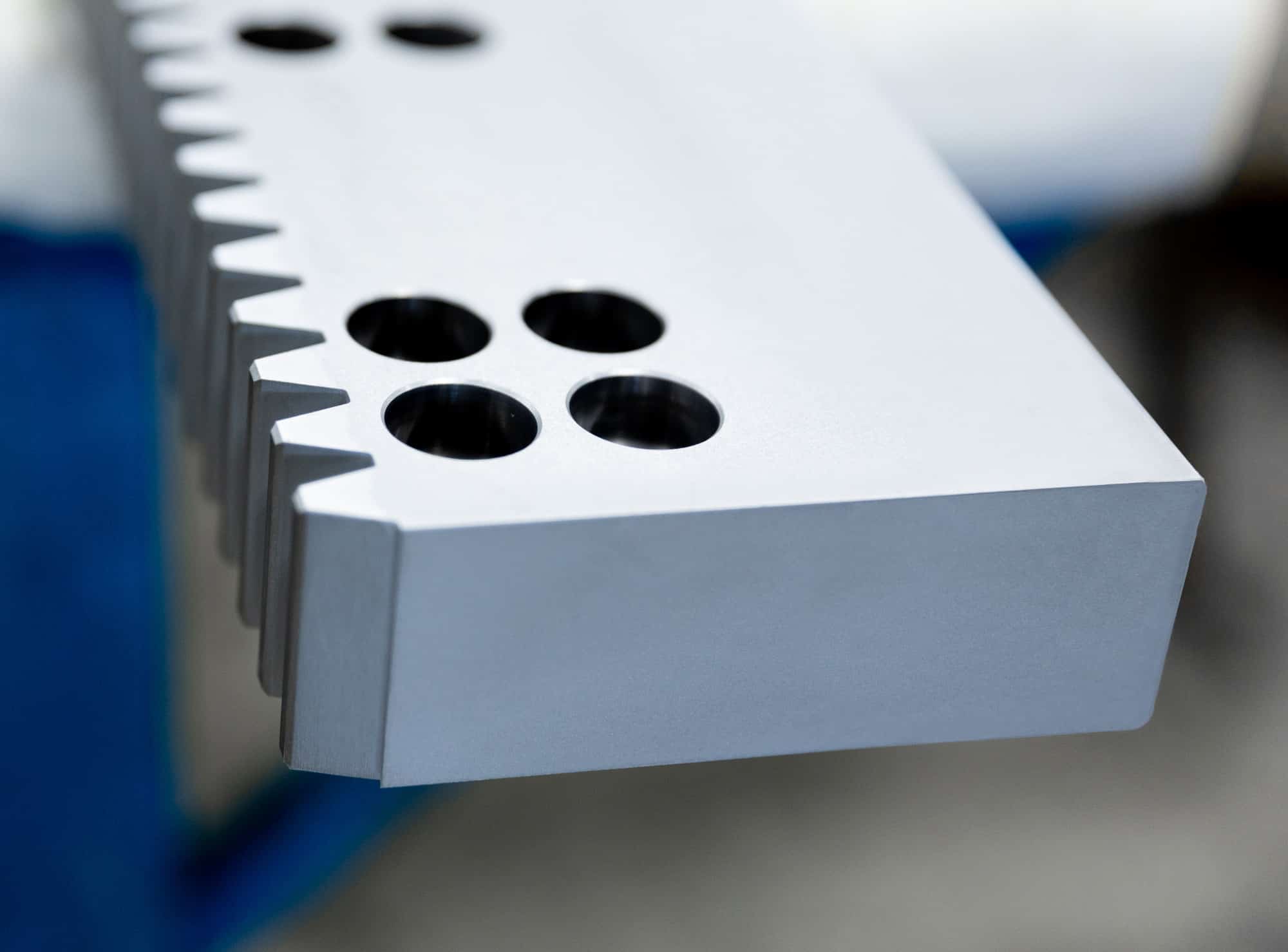

The Innovation Center is a nexus of metallurgical expertise and chemical research, dedicated to advancing coating and plating technologies for a wide range of industry professionals, including equipment manufacturers and engineers. This facility blends technical precision with practical application, fostering an environment where collaborative research and development thrive. As a hub for innovation, it plays a crucial role in shaping the future of metallurgical science, ensuring solutions are not only cutting-edge but also reliable and applicable in real-world scenarios.

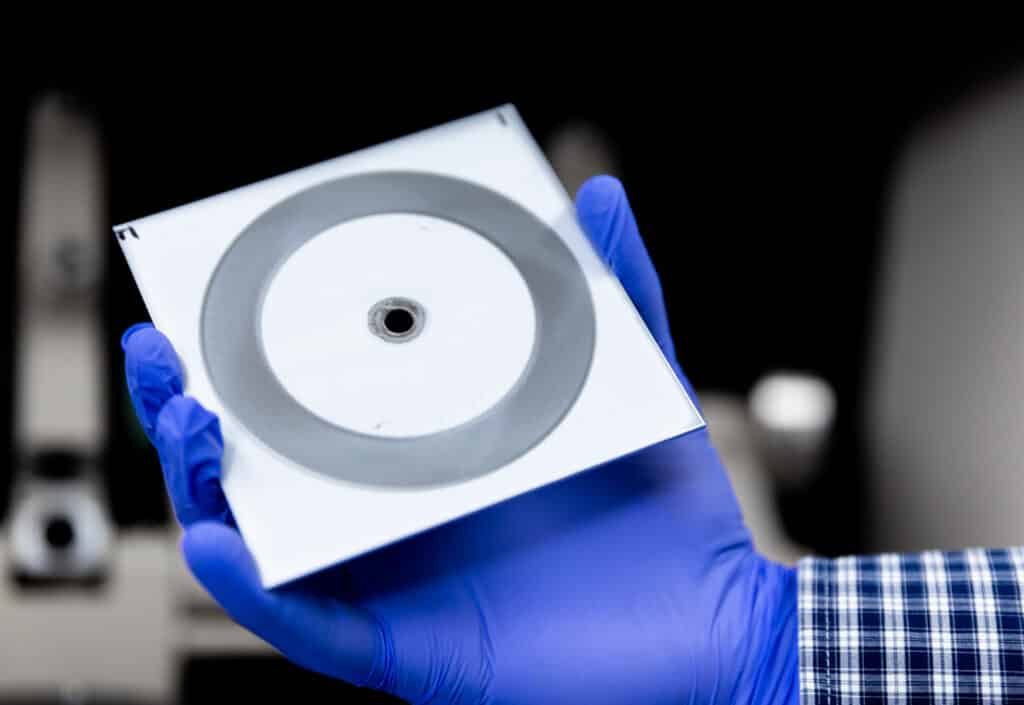

Process Development Center

A collaborative extension of the Innovation Center, the Process Development Center focuses on refining electroplating processes to their highest potential with minimal cost. This hub designs and develops custom tooling, processes, and training programs, ensuring uniformity and excellence in quality control across all Armoloy locations. Catering to a range of professionals, from supply chain specialists to reliability engineers, the center is a crucible of innovation and efficiency. Every procedure is precisely documented to set industry-leading expectations for quality and efficiency, embodying Armoloy’s commitment to delivering top-tier results at the least possible cost.

Fulfillment Centers

The Fulfillment Centers, central to Armoloy’s supply chain solutions, ensure consistent, efficient, and cost-effective coating and plating services. Integrated with the Corporate Laboratory and Innovation Center, they provide thorough support, including training and analytical services. Strategically positioned across several countries, the Armoloy fulfillment centers effectively meet diverse regional demands and industry-specific standards, significantly reducing lead times and costs while maintaining excellence in global operations.

Our Approach to Engineered Solutions

The team members at Armoloy take a partner-focused approach that centers on their unique requirements and situation. For instance, customers with a sudden, reactive need for a specific solution will generally have a much shorter timeline due to time-sensitive issues that need immediate resolution. One example would be a metal surface failure, which would cause unplanned downtime and require swift repairs to minimize revenue losses.

Customers interested in improving their products or processes for improved long-term efficiency should expect an entirely different timeline. Since this approach is more proactive, the process will be longer and more intensive. It starts by performing an initial consultation to review engineering, timing, cost, and logistical requirements—followed up further due diligence to ensure complete understanding of your project’s requirements.

Then, we utilize true turnkey research and development to inform our process development decisions and ensure that your metal coating solution fits your project’s requirements—before performing process, design, and production validation of the solution.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.