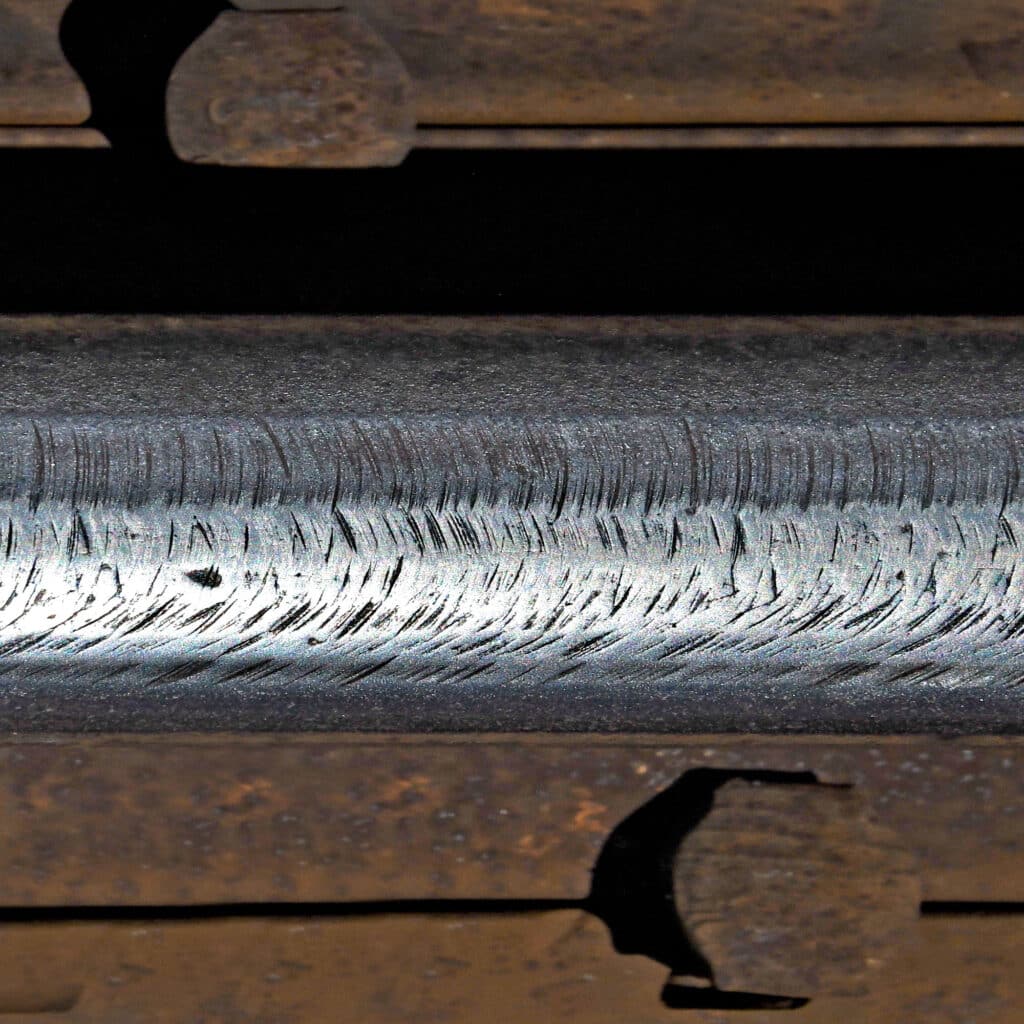

microcracked thin dense chrome

The Electrolizing Process

The Original Thin Dense Chrome Since 1945

The Armoloy Corporation helps global manufacturers protect their most valuable metal assets with our premium Thin Dense Chrome coatings.

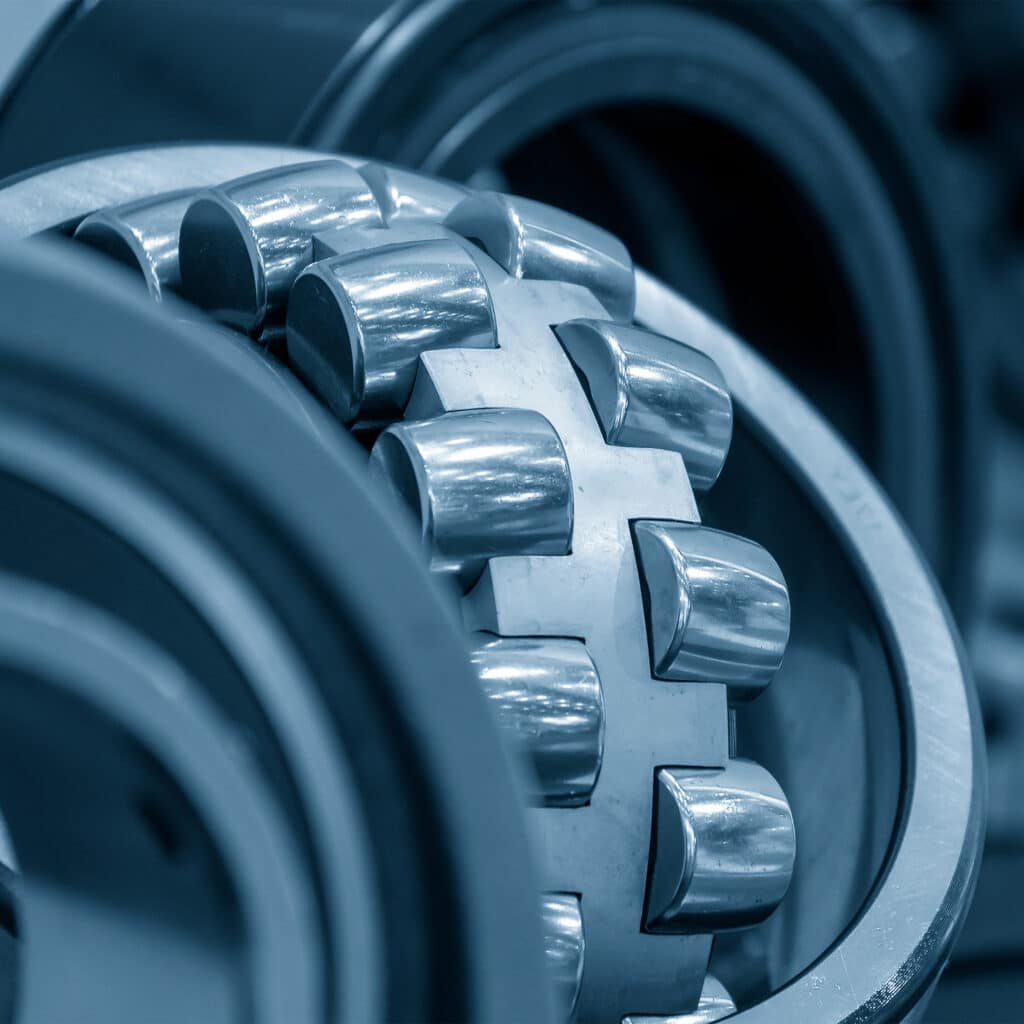

Electrolizing Microcracked Thin Dense Chrome (TDC) remains a dependable choice among Armoloy’s offerings for global manufacturers, serving as a reliable solution to reduce friction, combat wear and corrosion, enhance lubrication properties, and reinforce metal surfaces across diverse applications, ultimately extending their longevity and enhancing operational reliability.

Microcracked TDC Highlights

- Excellent wear resistance

- High surface hardness

- Low friction coefficient

- Improved lubrication retention

- Non-Magnetic

- Eliminates galling

- Absolute adhesion to substrate

- Multiple finishes available - matte, satin, non-reflective

Proven applications

Armoloy’s Microcracked TDC coating can improve the long-term performance of applications within the following industries, as well as many others:

- Plastic Injection Molding

- Machined Components

- Pumps & Compressors

- Food Processing & Packaging

- Automation & Linear Motion

- Oil & Gas Extraction

- Medical

- Aerospace

- Nuclear

- Renewable Energy

Certifications

- AMS 2438

- AMS 2460

- USDA Approved

- FDA Compliant

- USP 10993-10

- BAC 5709

- USP 10993-6

- USP 10993-11

Performance Characteristics

Microcracked TDC by the Numbers

- Surface hardness up to 72Rc

- Corrosion resistance tested to AMS 2438 per ASTM B-117

- Wear resistance less than 1.2 TWI per AMS 2438

- Up to 56% reduction in coefficient of friction

- Bond strength of 125,000 PSI

- Coating applied at a temperature below 180°F (82°C)

- Effective deposits as low as 0.00005 to 0.001” (1.27 to 25.4 µm)

- Maximum service temperature of 1600°F (871°C)

- Thermal expansion of 2.7 – 4.6 (10¯⁶/°F)

Microcracked Thin Dense Chrome

Features & Benefits

Pure metallic non-toxic chromium coating

USDA approved coating and FDA compliant, non-toxic (USP tested, REACH compliant, RoHS compliant), biocompatible surface

Low processing temperature

Protects parts from distortion and annealing

Diverse compatibility

Performs on most ferrous and non-ferrous metals

Effective at thin deposits

Won’t affect part tolerances and eliminates edge build-up

Absolute adhesion

Will not flake, crack, or separate from the base metal

Chemical resistance

Stable in acids, alkalis, solvents and gasses

Anti-galling characteristics

Excellent resistance to adhesive wear, enhanced tolerance of low-lube

No sharp edge buildup

Minimizes dimensional change

High wear resistance

Excellent for sliding applications where abrasion may occur

Lubrication retention

Retains dry and wet lubricants while lowering friction

Multiple appearances

Non-reflective, satin, and platinum appearances available

Biocompatible

Certified safe for use in medical devices, as well as clean-room applications

The Science Behind Microcracked Thin Dense Chrome

Our process for Microcracked TDC involves a carefully monitored solution and application process. This particular product uniformly deposits a dense, pure chromium and nonmagnetic alloy to the surface of a wide variety of applications.

Microcracked TDC offers the capability of utilization across a wide variety of industries. The end result is a hard, thin chromium coating that provides significant upgrades to common wear and corrosion resistance.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Improve metal surface performance to its highest pinnacle. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.