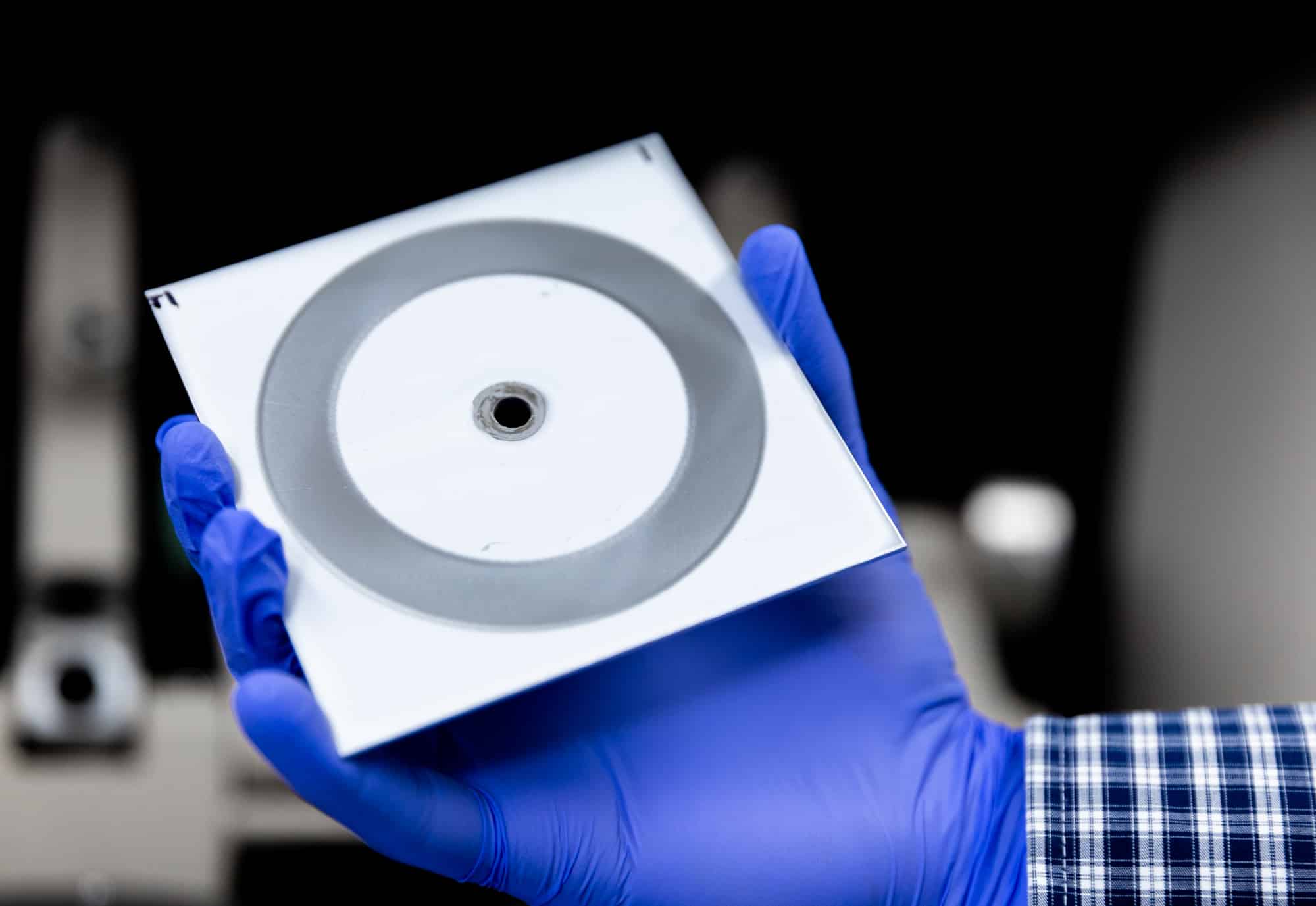

biocompatible nodular thin dense chrome

Surgical Coating for Life-Saving Tools

A Guard Against Harsh Sterilization Processes

Armoloy BIO TDC® and ME-92® are engineered to withstand repeated and rigorous sterilization processes essential in the medical field.

Our biocompatible surgical coatings are resistant to various sterilization methods including steam autoclave, STERIS SYSTEM 1, STERRAD Sterilization, and exposure to harsh chemicals. This resilience helps maintain the integrity and functionality of surgical instruments, ensuring they remain corrosion-free and retain their mechanical properties over time, thus extending their usable life significantly. Visit our ME-92® product page to compare our two biocompatible chromium coatings.

Request information

Performance Characteristics

BIO TDC by the Numbers

- Surface hardness up to 72Rc

- Uniform deposits from 0.000050″ – 0.0006″

- Certified biocompatible to ISO 10993-1

- Processing temperature < 160°F (<71°C)

- Bond strength of 125,000 PSI

- Corrosion resistance tested to AMS 2438 per ASTM B-117

- Up to 56% reduction in coefficient of friction

- Heat resistance of -400°F to 1400°F (-240°C to 760°C)

BIO TDC Highlights

- Meets USP class VI requirements

- Excellent corrosion resistance

- Stands up to repeated autoclaves

- Adheres to most base metals

- Improves wear resistance

- Anti-galling

- Improves cutting performance

- Non-reflective finish

Proven applications

Applying BIO TDC can improve the long-term performance of applications within the following industries, as well as many others:

- Medical instruments and devices

- Robotics

- Medical packaging

- Clean room applications

- Surgical tools

- Veterinary surgical tools

- Orthopedic tooling

- Endoscopic cutters

- Food processing and packaging

- Saws, taps, and drills

Certifications

- Aerospace Material Specification SAE AMS2460 | AMS-QQ-C-320, Chromium Plating (Electrodeposited)

- USP Class VI

- Tripartite/ISO

- STERIS SYSTEM 1

- Aerospace Material Specification SAE AMS2406

- SAE AMS2438 Plating, Chromium Thin, Hard, Dense Deposit

- Steam Autoclave

- STERIS EtO

- STERRAD Sterilization

BIO TDC Features & Benefits

Biocompatible

Certified safe for use in medical devices and instruments, as well as clean-room applications

Hydrophobic

Arrests moisture and water buildup, further enhancing corrosion resistance

Corrosion resistance

Protects instruments from rust and degradation due to frequent sterilization

Reduced light reflection

Ideal for tools used in procedures requiring minimal light interference such as laparoscopic surgery

Non-stick surface

Facilitates easy cleaning and reduces the risk of contamination

High surface hardness

Protects against scratches and abrasions, maintaining functional sharpness of surgical tools

Reapplication capability

Coatings can be removed and reapplied without affecting the base material, which is beneficial for refurbishing and reusing medical tools

Absolute adhesion to base material

Maintains cutting edges and provides a hard, scratch resistant, nonstick, easy to clean surface

The Science Behind BIO TDC

Biocompatible thin dense chrome plating is achieved through an electrolytic process that involves the deposition of chromium onto a substrate from a chromium-containing electrolytic solution. The substrate serves as the cathode, where the metal ions are reduced and bond to the surface, forming a dense, hard layer. This process is meticulously controlled to ensure that the coating adheres strongly to the substrate without altering its properties or dimensions.

The thickness of the chrome layer can be precisely controlled to meet specific medical standards, ensuring optimal performance across various applications. The result is a robust, wear-resistant, and visually appealing surface that can significantly enhance the performance and safety of medical devices

Explore Further: 7 Benefits of Biocompatible Coatings for Surgical Instruments

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Need a nodular surgical finish? Let’s protect your instruments.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.