Medical Coating

Creating More Effective Medical Instruments

The ME-92 medical coating process is a proprietary electroplating technique that yields a microcracked surface texture and imparts a hard, nonstick, uniform metallic chromium surface deposit.

This uniform, thin layer guarantees that part tolerance and balance are maintained without the necessity for subsequent machining, even when dealing with intricate shapes, all while delivering simultaneous benefits regarding protective qualities and performance improvements.

Enhancing Applications Across the Medical Industry Worldwide

The Armoloy Corporation helps medical professionals protect their high-precision devices and instruments with our biocompatible medical coatings.

ME-92, initially designed for surgical instruments, is the preferred solution for use in lab environments, cleanrooms, and a wide range of medical applications, and it’s also well-suited for food processing equipment. This preference arises from the process’s exceptional cleanliness and minimal exposure to contact materials. ME-92 improves lubrication properties, is chemical resistant, easy to clean, and strengthens metal surfaces for wear and corrosion applications as well. The anti-microbial and hydrophobic nature of ME-92 coating surfaces safeguards against bioburden while withstanding hundreds of autoclave sterilization cycles—without staining or discoloration.

With multi-value attributes and benefits, ME-92 prolongs the lifespan of critical equipment, enhances performance consistency, and effectively eliminates contamination risks. The ME-92 process also offers multiple sheen and color variations to cater to non-reflective applications and meet aesthetic preferences.

Performance Characteristics

ME-92 by the Numbers

- Surface hardness up to 72Rc

- Deposit thickness ranging from 0.00004” to 0.001” (1.016 to 25.4 µm)

- Processing temperature < 160°F (<71°C)

- Bond strength of 125,000 PSI

- Corrosion resistance tested to AMS 2438 per ASTM B-117

- Certified biocompatible to ISO 10993-1

- Porosity tested per AMS 2460

- Withstands temperatures of -400°F to 1600°F (-240°C – 870°C)

- Thermal expansion of 2.7 – 4.6 (10¯⁶/°F)

- Up to 56% reduction in coefficient of friction

- Wear resistance less than 1.2 TWI per AMS 2438

Armoloy ME-92 Highlights

- High surface hardness

- Hydrophobic

- Excellent wear resistance

- Absolute adhesion

- Eliminates galling

- Non-magnetic

- Compatible with nearly every base metal type

- Non-reflective, platinum and satin finishes available

- Antimicrobial

Proven applications

Applying ME-92 biocompatible medical coating can improve the long-term performance of applications within the following industries, as well as many others:

- Medical instruments and devices

- Medical packaging

- Surgical tools

- Veterinary surgical tools

- Robotics

- Clean room applications

- Pharmaceutical packaging

- Orthopedic tooling

- Endoscopic cutters

- Dental reamers

- Saws

- Taps

- Drills

- Laboratory environment

- Stamps

- Dies

- Rolls

- Pumps & valves

- Mobile medical devices

- Refurbishment of surgical tools & equipment

Certifications

- SAE AMS2438 Plating, Chromium Thin, Hard, Dense Deposit

- Aerospace Material Specification SAE AMS2406

- Aerospace Material Specification SAE AMS2460 | AMS-QQ-C-320, Chromium Plating (Electrodeposited)

- USP Class VI

- Tripartite/ISO

- Anti-microbial

- Sterilization Procedures Including:

- Steam Autoclave

- STERIS SYSTEM 1

- STERRAD Sterilization

- Gamma X Ray

- Bleach Exposure

- Boiling

- Detergent scrubbing

- STERIS EtO

- Cytotoxicity tested

- Hemolysis tested

- Intracutaneous tested

- Pyrogen tested

- Systemic Toxicity tested

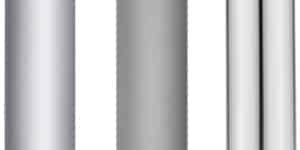

ME-92® Finish Comparison

ME-92® Medical Coating is available in three finishes – satin, non-reflective, and platinum

ME-92 Features & Benefits

Biocompatible

Certified safe for use in medical devices and instruments, as well as clean-room applications

Absolute adhesion to base material

Maintains cutting edges and provides a hard, scratch resistant, nonstick, easy to clean surface

Hydrophobic

Arrests moisture and water buildup, further enhancing corrosion resistance

Chemical resistant

Compatible with caustic sterilization procedures

Anti-microbial surface

Naturally eliminates buildup of harmful bacteria

Diverse appearances

Three finishes are available to suit your specific application: Non-Reflective, Platinum, and Satin

Completely inert

Will not cause or promote change in structure, maintaining component integrity

No sharp edge buildup

Minimizes dimensional change

Improved fatigue life

Hard surface of chromium reduces surface roughness, increasing fatigue life in certain components

Temperature resistant

Chrome coatings perform well at high temperatures, maintaining their protective properties

Low friction

Significantly increases life of rolling and sliding applications

Barrier against base metal allergens

Eliminates patient sensitivity to base metals such as nickel

The Science Behind ME-92

How it Works

The design of Armoloy’s ME-92 pure biocompatible chromium coating makes it uniquely engineered to serve the medical industry.

Applied with the utmost precision, this coating is completely inert and developed in a highly sanitized facility free of latex to meet all necessary compliance measures.

The process for developing ME-92 medical coating will begin by obtaining customer’s individual production requirements—including metal finish, deposit thickness, and more. When developing the ME-92 coating, our team of experts utilize electrolytic plating and a low-temperature process to uniformly apply the pure metallic chromium. This process ensures that the integrity of the application’s material remains intact.

By bonding the coating to the application’s material, Armoloy ensures absolute adhesion and high ductility. This means that the coating will not only prevent chips, flakes, and peels, but also any separation from the material under stress. The end result is a dramatic improvement to the instrument’s appearance and performance—as well as its longevity by:

- Reducing wear and corrosion

- Improving surface hardness and chemical resistance

- And eliminating galling

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Improve metal surface performance to its highest pinnacle. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.