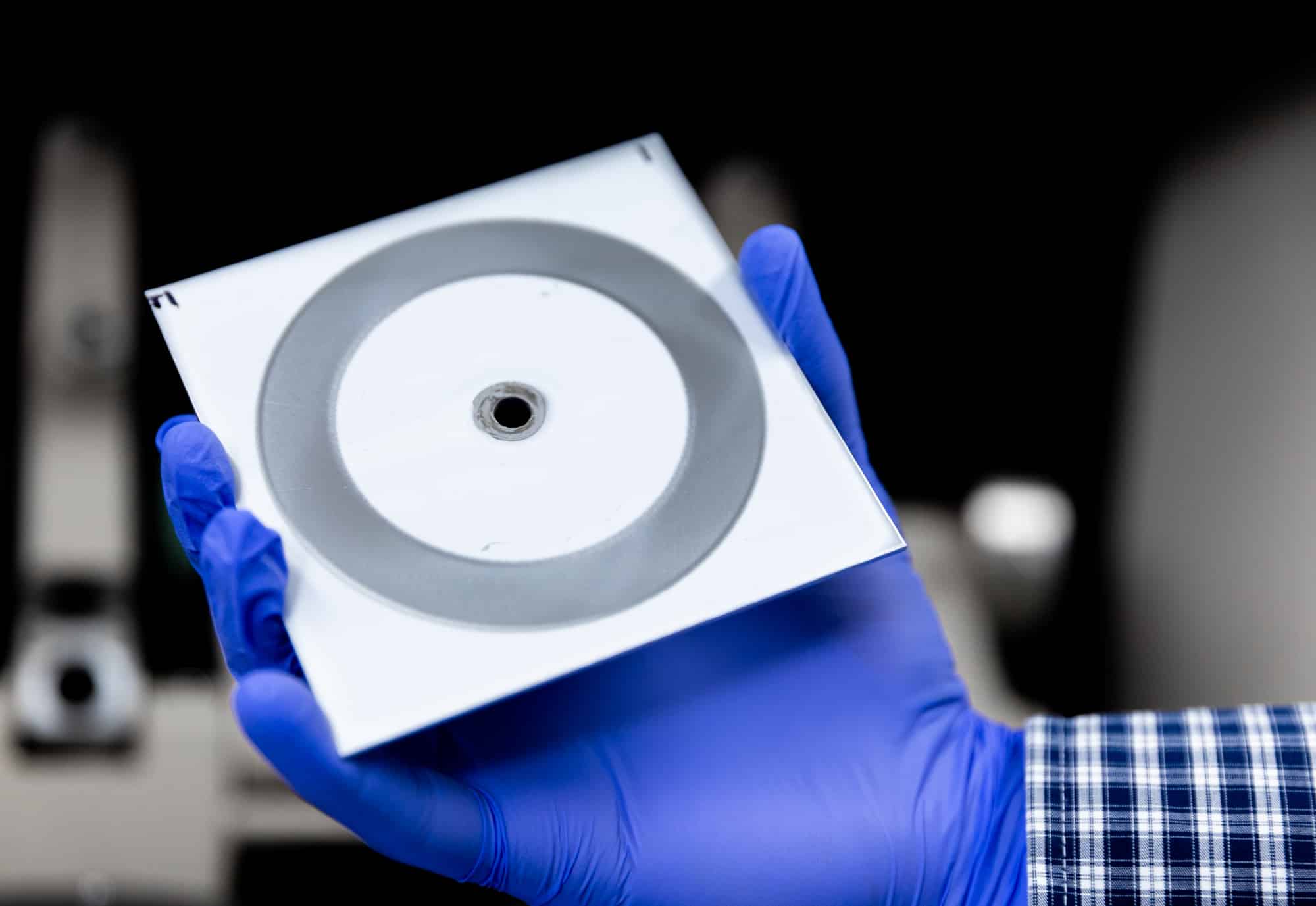

solid film chrome coating

What is Gullon®

By layering nodular TDC® with a tailored solid-film lubricant, Gullon creates a duplex system that delivers exceptional surface hardness, low friction, and long-term corrosion resistance—without compromising dimensional tolerances.

The micronodular TDC base offers up to 78 Rc hardness and absolute adhesion to ferrous and non-ferrous metals. Over this, a thermoset solid-film lubricant—such as PTFE, MoS₂, or graphite—is applied and bonded to meet specific performance demands, including dry lubrication, galling prevention, and chemical exposure resistance.

Gullon is especially effective in powder-injection-molded parts, medical and food-grade components, linear motion systems, and other applications where lubrication is limited or inaccessible. The result is a low-maintenance, self-lubricating metal surface that resists wear and reduces unplanned downtime.

Optimal Lubricity with Wear Resistance

The Armoloy Corporation helps global manufacturers protect their most valuable, high-precision components with a broad spectrum of engineered compositions of thin dense chrome coatings.

At Armoloy, our engineering team meticulously assesses each application to select the most suitable surface texture and co-deposit. This careful and technical process not only protects metal components from potential failures but also enhances their operational efficacy and durability. With the introduction of Gullon®, a hybrid coating solution, we have made a notable advancement in addressing the challenges of friction and load bearing for metal components.

Performance Characteristics

Gullon by the Numbers

- Surface hardness up to 78Rc

- Taber Wear Index (TWI) as low as 0.7

- 1000+ hrs Salt Spray

- 10% – 67% reduction in coefficient of friction

- Effective deposit range of .000050” to .0007” (1.27 to 17.78 µm)

- Low processing temperature, <150° F (<65°C)

Gullon Highlights

- Chemically resistant

- Improved corrosion resistance

- Inherently lubricious

- Prevents galling

- Absolute adhesion

- Load bearing

Proven applications

Applying Gullon® can improve the long-term performance of applications within the following industries, as well as many others:

Certifications

- Aerospace Material Specification SAE AMS2438 Plating, Chromium Thin, Hard, Dense Deposit

- MIL—C-23422 Military Specification, Chromium Plating, Electrodeposited

- Aerospace Material Specification SAE AMS2406

- Aerospace Material Specification SAE AMS2460 | AMS-QQ-C-320, Chromium Plating (Electrodeposited)

- ASTM B650 Standard Specification for Electrodeposited Engineering Chromium Coatings on Ferrous Substrates

Gullon® Features & Benefits

High wear resistance

Provides exceptional durability against wear and tear

Enhanced lubricity

Reduces friction, enhancing the efficiency and lifespan of components

Corrosion resistance

Offers protection against corrosive environments, extending component life

Absolute adhesion

Coating adheres atomically to base metals, preventing peeling, chipping, and flaking

Low friction

Maintains a low coefficient of friction (0.02 to 0.10), ideal for moving parts

Load bearing capacity

Combines strength with elasticity, supporting heavy loads without deformation

Thin, precise deposits

No post plate machining required. Does not affect part tolerances or balance

No sharp edge buildup

Minimizes dimensional change

The Science Behind Gullon®

How Gullon Hybrid Coating Works

Gullon combines two surface technologies—a nodular Thin Dense Chrome (TDC®) base and a cured solid-film lubricant—to create a single, bonded coating system that performs under extreme wear, load, and environmental stress.

Unlike conventional coatings that rely on a single material to provide all performance properties, Gullon separates functions between its layers. The TDC layer delivers compressive strength, hardness, and corrosion resistance, while the top solid-film layer reduces friction, prevents galling, and improves dry running capability. Each layer is applied in a controlled, thin deposit (typically 0.00035″), preserving tolerances and enabling use on complex geometries or porous components.

The result is a duplex coating architecture engineered to outperform standalone chrome or solid-lubricant systems, especially in applications where traditional lubrication is impractical or failure-prone.

Gullon Surface Architecture and Bonding

At the core of Gullon’s performance is its nodular TDC foundation: a dense, microstructured chrome layer with a hardness rating up to 78 Rc. Unlike standard hard chrome, which relies on microcracks for lubricant retention, TDC forms a uniform nodular texture that enhances bonding and resists chipping or delamination.

This structure provides a high-integrity anchor surface for the second layer: a thermoset solid-film lubricant selected for the application. Once applied, the lubricant is bonded and cured over the TDC base, forming a chemically resistant top layer that enhances lubricity and further protects the substrate from mechanical and chemical stress.

Because both layers are applied at low thicknesses and low temperatures, Gullon coatings maintain part geometry and are safe for use on sensitive alloys or porous metals, such as powder-injection-molded (PIM) stainless steel.

Choosing Your Solid-Film Lubricants

Gullon’s performance is largely defined by the solid-film lubricant selected for the top layer. This material is chosen for the specific use case, factoring in frictional load, operating temperature, chemical exposure, and re-lubrication restrictions.

Armoloy engineers typically use one or more of the following:

- PTFE (Polytetrafluoroethylene): Offers extremely low friction and excellent chemical resistance in both wet and dry environments.

- MoS₂ (Molybdenum Disulfide): Excels under high loads and in vacuum or dry-running applications where oil-based lubricants cannot be used.

- Graphite: Provides consistent lubrication across wide temperature ranges and environmental conditions, especially where humidity or thermal cycling is a factor.

- Hybrid blends: For specialized needs requiring a balance of friction control, thermal stability, and anti-corrosion performance.

These lubricants are embedded in a resin matrix, then heat-cured to form a bonded, wear-resistant film. The resulting surface resists chemical degradation, prevents sticking and seizing, and functions as a dry-lubricated system across a wide range of industries.

Built for Clean, Maintenance-Limited Environments

- Dry-running conditions

- Corrosive fluids or chemical washdowns

- Extreme loads and contact pressures

- Cleanroom or sanitary regulations (medical, food, packaging)

Because the coating typically requires no reapplication, it can significantly extend the service life of components that are inaccessible or subject to strict cleanliness standards. Gullon also prevents galling, a form of adhesive wear common in stainless steel and PIM parts, making it especially valuable for metal-on-metal assemblies and motion systems.

Explore other Hybrid Coatings

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Seeking a custom solution? Let’s engineer your hybrid coating.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.