Yes. Armoloy offers biocompatible coating options like ME-92 and BIO-TDC, both of which meet the requirements of ISO 10993 testing for surgical and implantable devices. These coatings are used on instruments that contact tissue and fluids, and we provide full documentation to support FDA and regulatory submission requirements for surgical tools.

operating at the highest level

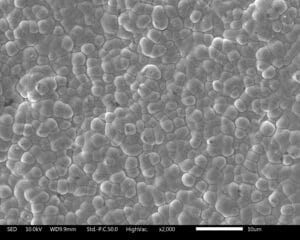

Cutting-Edge Surgical Instrument Coatings

Benefits of Surgical Instrument Plating Services from Armoloy

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Start-to-Finish Coating Expertise

- Armoloy delivers complete surface treatment services tailored for high-performance tools and components. From early design collaboration to final quality checks, our team ensures each part is coated with consistency, durability, and precision.

Validated Processes for Critical Applications

- At our innovation center, we develop and test coating methods engineered for repeatability and clean performance. These qualified processes are implemented globally to ensure every surgical tool receives the same reliable finish—regardless of location.

Worldwide Delivery with Trusted Quality

- With fulfillment centers around the world, Armoloy provides dependable logistics and uniform coating standards. Wherever your surgical tools are manufactured or assembled, we help ensure they arrive coated to spec and ready for use.

Process Accreditations at Armoloy

Armoloy’s surgical instrument coatings are reliable, safe, and high-performing solutions for demanding medical environments. Our biochrome coatings have passed the rigorous testing processes to qualify for the following accreditations:

- ISO 10993

- ISO 10993-6

- REACH Compliance

- ISO 10993-11

- ISO 10993-10

- RoHS Compliance

Certifications at Armoloy

Armoloy’s surgical instrument coatings are reliable, safe, and high-performing solutions for demanding medical environments. Our biochrome coatings are tested and certified to the following specifications:

- AMS2460 SAE, Plating, Chromium

- USP Class VI

- Tripartite/ISO

- STERIS SYSTEM 1

- SAE AMS2406

- SAE AMS2438 Plating, Chromium Thin, Hard, Dense Deposit

- Steam Autoclave

- STERIS EtO

- STERRAD Sterilization

Surgical Coatings Applications

Armoloy biochrome coatings improve the performance and durability of a wide range of surgical instruments and equipment, including:

- Medical instruments & devices

- Handles/Housings/Tubing

- Veterinary Surgical Tools

- Clean room applications

- Orthopedic tooling

- Saws/Taps/Drills

- Endoscopic cutters

- Dental reamers

- Laboratory environments

Frequently Asked Questions

Not at all. Our thin dense chrome coatings are applied at controlled thicknesses as low as 0.00005″, allowing them to protect scalpels, scissors, forceps, and microsurgical tools without affecting blade sharpness or mechanical fit. The result is improved performance and durability without compromising tactile feedback or precision, even on aluminum devices.

Armoloy coatings provide a chemically inert, corrosion-resistant surface that stands up to autoclaving, steam sterilization, and harsh disinfectants without pitting, staining, or degrading. Unlike untreated stainless steel, our coatings preserve the instrument’s surface integrity after hundreds of sterilization cycles, helping extend tool life and maintain a pristine surgical appearance.

Demanding surgical precision? Let’s talk biocompatible coatings.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.