Absolutely. Armoloy coatings are applied with tight thickness control (as low as 0.00005), making them suitable for aluminum, titanium, and precision-machined alloys commonly used in lightweight and high-speed robots. They add durability without adding significant weight or altering critical tolerances—key for performance in space-limited or payload-sensitive designs.

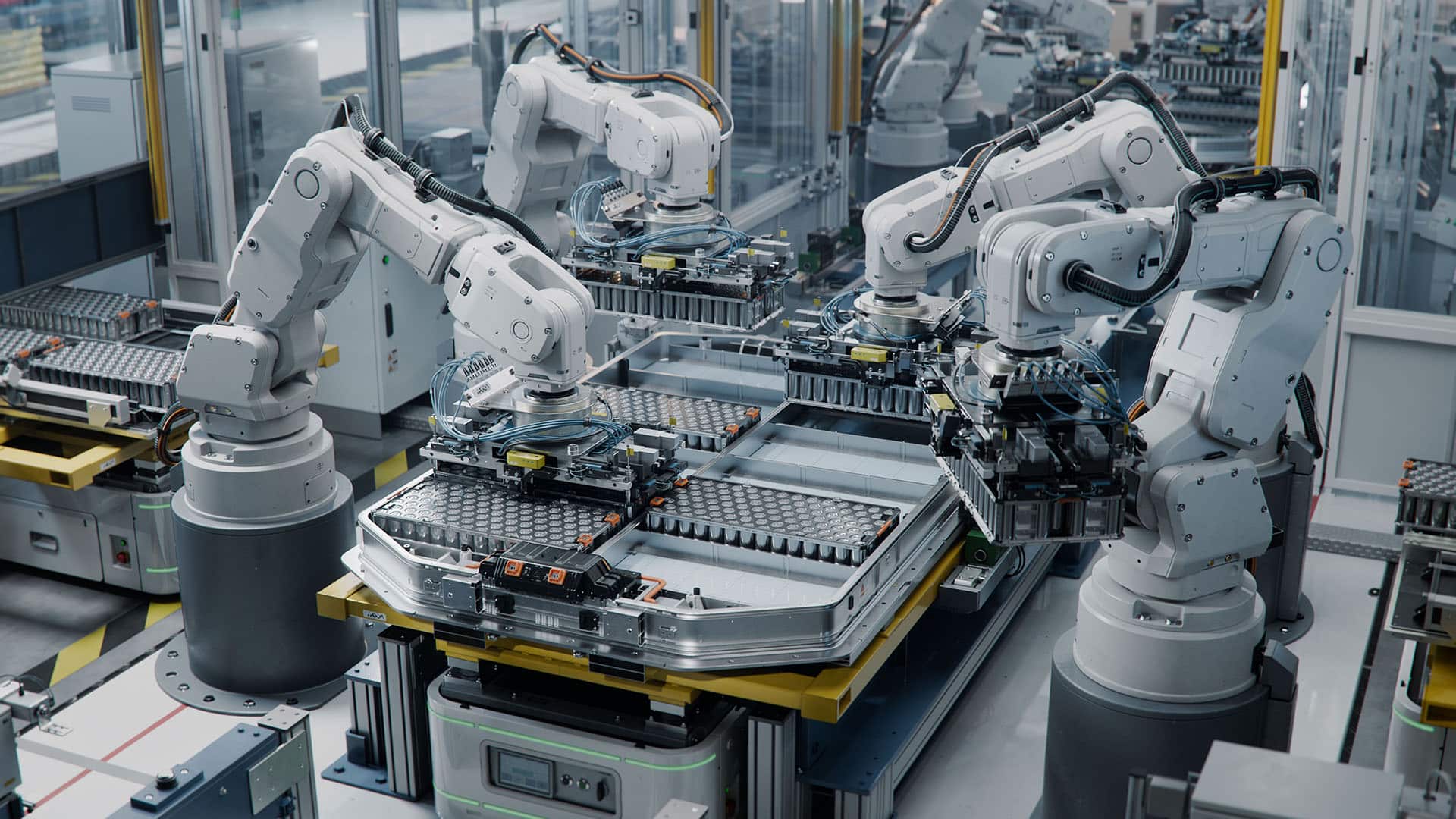

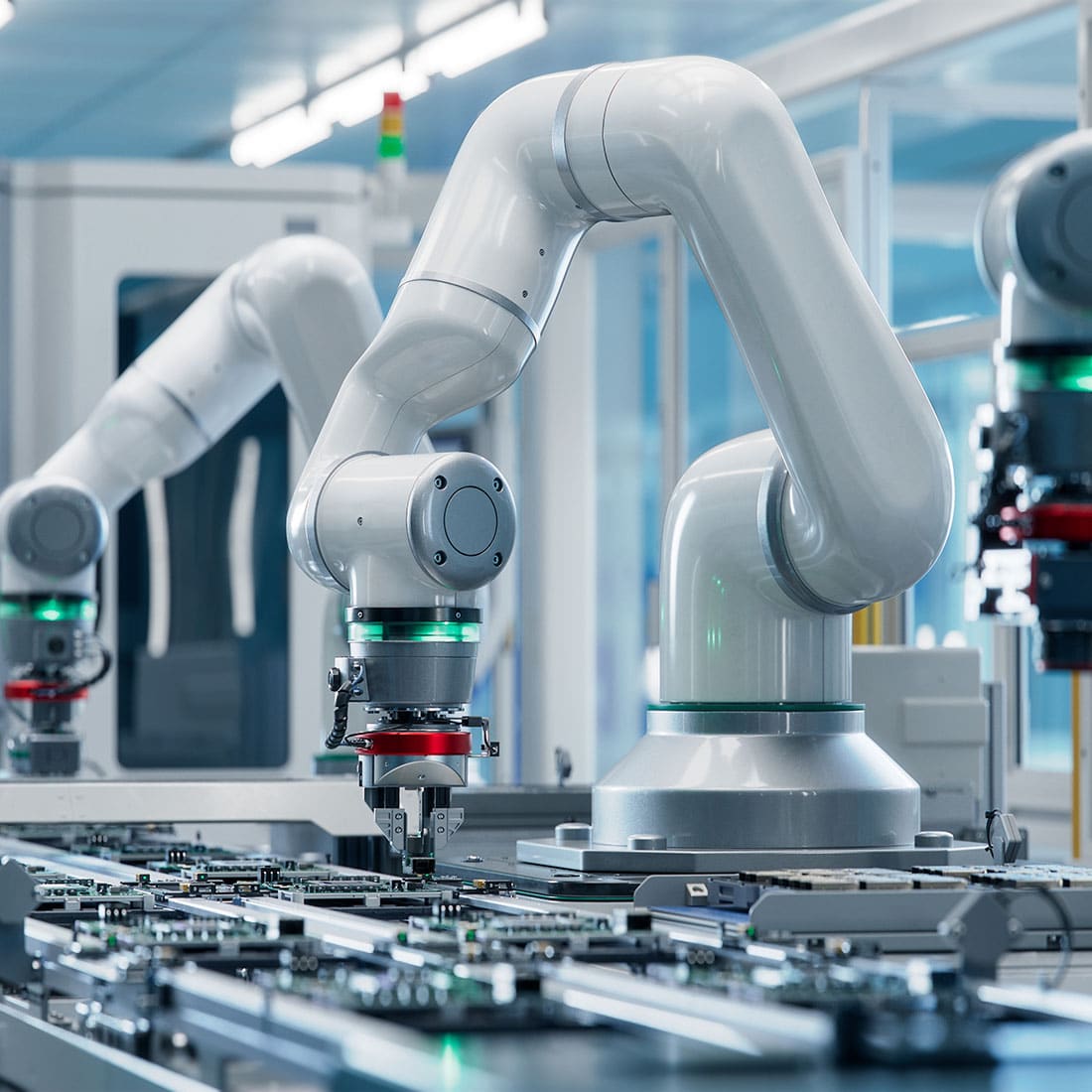

accelerating automation

The Purpose of Robotics Plating

Benefits of Robotics Plating Services from Armoloy

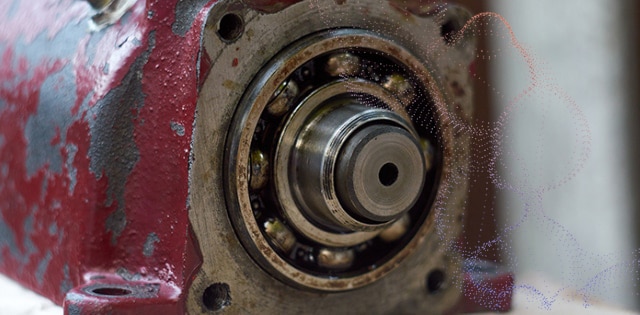

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Coating Support from Start to Finish

- Armoloy delivers full-scope surface treatment solutions designed to support high-performance systems. From early-stage consultation through application and final inspection, our team ensures each component is coated with precision and reliability in mind.

Standardized Processes, Scalable Results

- Our innovation center develops coating methods that are tested for repeatability and efficiency. Once qualified, these processes are implemented globally to deliver consistent results across a wide range of robotic applications.

Global Reach, Consistent Execution

- With fulfillment centers positioned around the world, Armoloy ensures timely delivery and uniform quality—enabling smooth integration of coated components into automation systems, wherever they’re built or deployed.

Process Accreditations at Armoloy

Armoloy robotics coatings have passed the rigorous testing qualifications for the follow industry accreditations:

- AS9100D

- ISO 9001:2015

- ISO 10993

- RoHS Compliance

- NADCAP

- ISO 19011

- ISO 14001:2015

- WEEE Compliance

- REACH Compliance

Coating Specifications at Armoloy

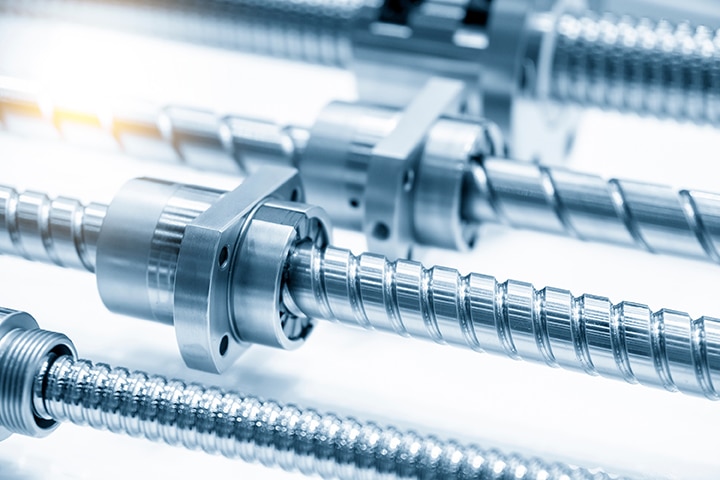

Armoloy robotics coatings comply with AMS 2438, AMS 2460, and most customer-specific standards throughout the chrome coatings industry. We operate processing tanks dedicated to AMS 2438 requirements, and our coatings can be applied to nearly all ferrous and non-ferrous base materials.

Robotics Coatings Applications

Armoloy coatings enhance the functionality of various robotics components and applications, including:

- Ball, swivel, universal & slip joints

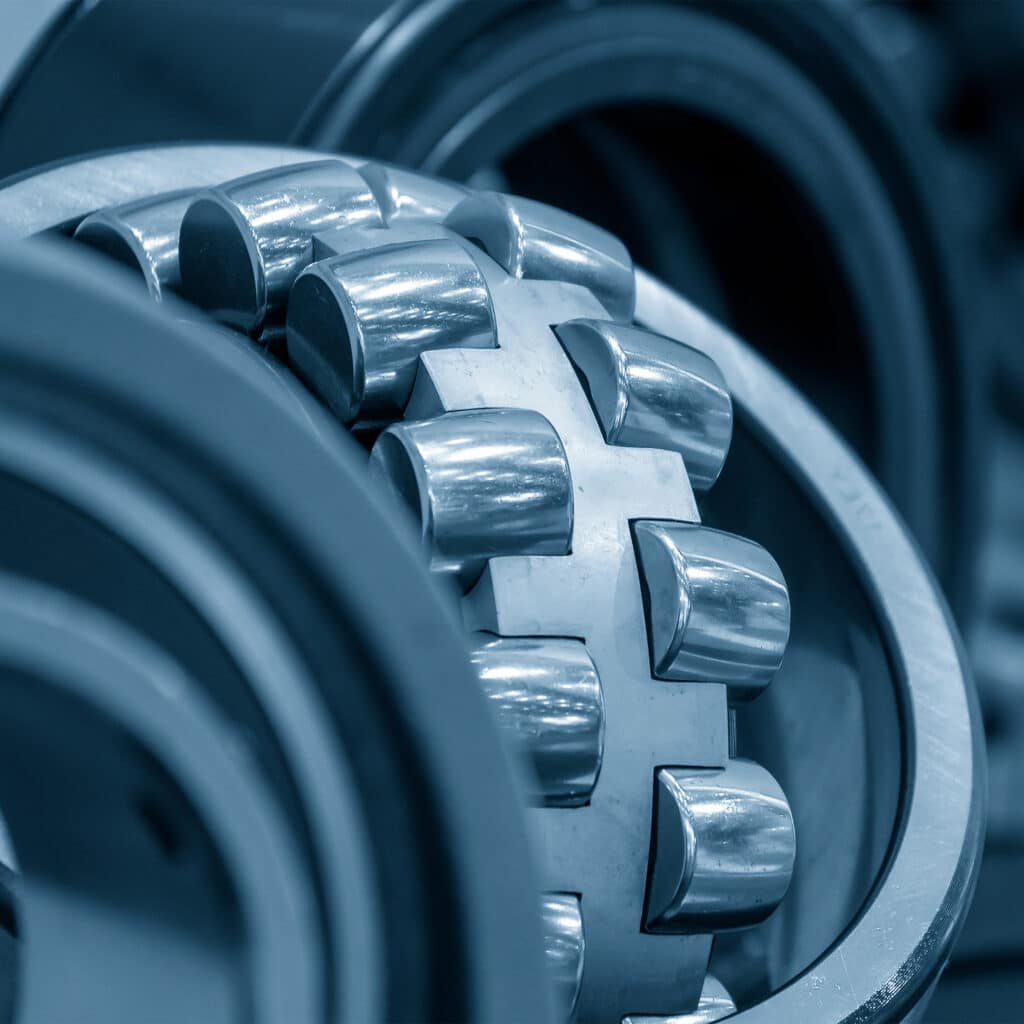

- Bearing surfaces

- Bushings

- Cylinders

- Data processing equipment

- Electronic components

- Gears & sprockets

- Hydraulic valves, pistons, & housings

- Linear motion guides

- Robotic joints

Frequently Asked Questions

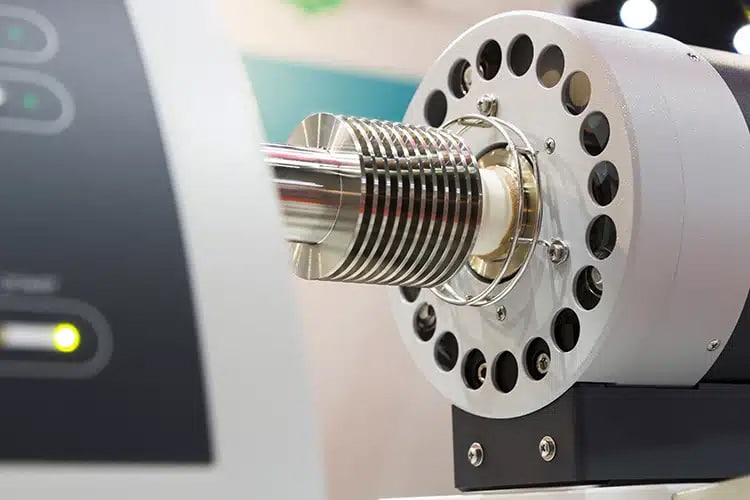

Yes. Armoloy’s thin dense chrome coatings create a low-friction surface that minimizes stick-slip behavior and reduces wear at sliding interfaces. This helps robotic joints, bearings, and actuator components operate smoother and with less energy loss, improving efficiency, accuracy, and mechanical life in both high-speed and high-load applications.

Armoloy coatings are ideal for robotic arms, linear actuators, ball screws, end effectors, gripper jaws, gears, and motion control components. These parts require low-friction movement, wear resistance, and precision surface finishes to maintain long-term reliability in industrial, medical, and collaborative robotic systems.

Engineering precision movement? Let’s boost reliability.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.