Armoloy Coatings

What is Zinc Phosphate?

It’s standardized globally (e.g., ISO 9717:2024) and in U.S. defense specs (e.g., MIL-DTL-16232 for heavy zinc/manganese phosphate and TT-C-490 for pretreatment systems).

Why Engineers Choose ZnPh

Paint + powder adhesion: Stable, high-surface-area anchor profile reduces blistering/undercutting under salt spray.

Corrosion protection as a system: Alone, phosphate helps little; with oil or paint/e-coat/powder, performance rises dramatically.

Friction control & anti-galling: Porous crystal network retains oils/solid film lubricants for run-in and sliding parts.

The Types of Phosphate Coatings

Phosphate coatings are classified by industry standards based on composition, coating weight, and intended use. The two most widely used systems are U.S. military/federal specifications and ISO standards:

U.S. Federal Specification TT-C-490H

Defines phosphate pretreatments primarily for paint and powder coating adhesion:

- Type I – Zinc Phosphate (150-500 mg/ft²): Fine, crystalline coating for paint adhesion and corrosion resistance.

- Type II – Iron Phosphate (≥35 mg/ft²): Lightweight pretreatment to improve paint adhesion on steel.

- Type III – Organic Pretreatments: Wash primers or adhesion promoters with high organic content.

- Type IV – Inorganic Pretreatments: Non-chrome, inorganic adhesion promoters.

- Type V – Medium-Weight Zinc Phosphate (500–1100 mg/ft²): Higher coating weight zinc phosphate for enhanced corrosion resistance.

U.S. Military Specification MIL-DTL-16232H

Covers heavier phosphate coatings for wear, lubrication, and corrosion resistance:

- Type Z – Zinc Phosphate: Heavy crystalline zinc phosphate coating, often used with oil for corrosion protection and anti-galling.

- Type M – Manganese Phosphate: Thicker, harder coating for wear and scuff resistance under severe service.

- Classes 1–4: Define post-treatments, such as with oil (Class 1), as a paint base (Class 2), or without supplementary treatment (Class 4).

ISO 9717:2024 (International Standard)

Uses a designation system to describe phosphate coatings, specifying:

- Substrate (e.g., Fe for steel)

- Phosphate type (ZnPh for zinc phosphate, MnPh for manganese phosphate, FePh for iron phosphate)

- Nominal coating mass

- Post-treatments (e.g., oiling, sealing, painting)

Performance Characteristics

Zinc Phosphate by the Numbers

Coating weight (pretreatment):

- Type I ZnPh: 150–500 mg/ft²

- Type V ZnPh: 500–1100 mg/ft² (medium-weight)

Coating weight (heavy ZnPh for oil retention): 1,000–3,000 mg/ft² typical; up to 3,000+ mg/ft² for cold-forming lines.

Typical thickness: ~5–15 μm (0.0002–0.0006 in.) for heavy ZnPh on steel (application-dependent).

Friction (representative): μ ≈ 0.15–0.20 dry; μ ≈ 0.09–0.15 with oil (ISO 16047 test conditions).

Corrosion (salt spray, ASTM B117):

- ZnPh + oil (heavy): ≥96 h common; “48 h easily” with conventional heavy ZnPh + oil.

- ZnPh + single powder coat: about 500–750 h (“better” tier).

- ZnPh + zinc-rich primer or e-coat + topcoat: 750–1000 h (“superior” tier). Actual results depend on paint system.

Note: Phosphate alone is not a barrier coating. The corrosion life mostly comes from the oil or paint system that the ZnPh layer supports.

- Paint and powder-coat pretreatment for steel structures, enclosures, and fabricated assemblies

- Fasteners & hardware where controlled friction and consistent clamp load matter

- Bearings, gears, slides, firearm/action parts needing oil retention and anti-galling

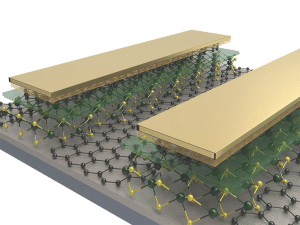

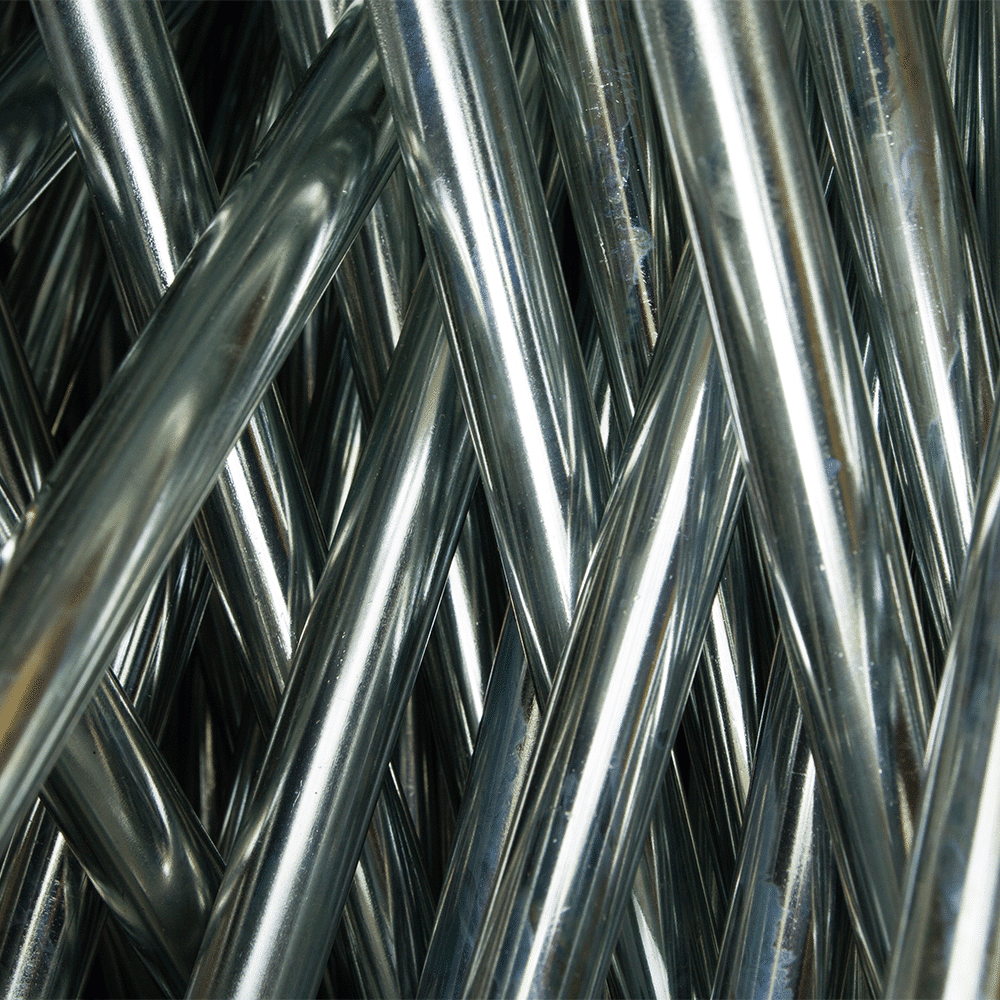

- Cold forming / wire & tube drawing (calcium-modified ZnPh + soap systems)

- MIL-DTL-16232 (Type Z, Classes 1–4) and MIL-STD-171 finish callouts for zinc phosphate

- TT-C-490H (Type I and Type V zinc phosphate; Type II iron phosphate pretreat)

- ISO 9717:2024 (phosphate conversion coatings terminology & requirements)

- ASTM F1137 (phosphate/oil or phosphate/organic for fasteners; grades 0A–III)

Zinc Phosphate Features & Benefits

Coating system durability

When used beneath powder or e-coat, ZnPh helps systems achieve 500–1000+ hours of B117 resistance, depending on the paint stack

Consistent friction window

Predictable torque-tension behavior (see μ ranges above) for bolted joints and sliding components

Oil retention & break-in

Heavy ZnPh (≥1,000 mg/ft²) absorbs rust preventives and oils for long-lasting lubrication and run-in protection

Process-proven & codified

Fully defined in DoD and ISO standards to streamline qualification and QA

Zinc Phosphating Process

What to Expect

- Degrease/ clean (solvent/alkaline/ultrasonic, as appropriate), then rinse.

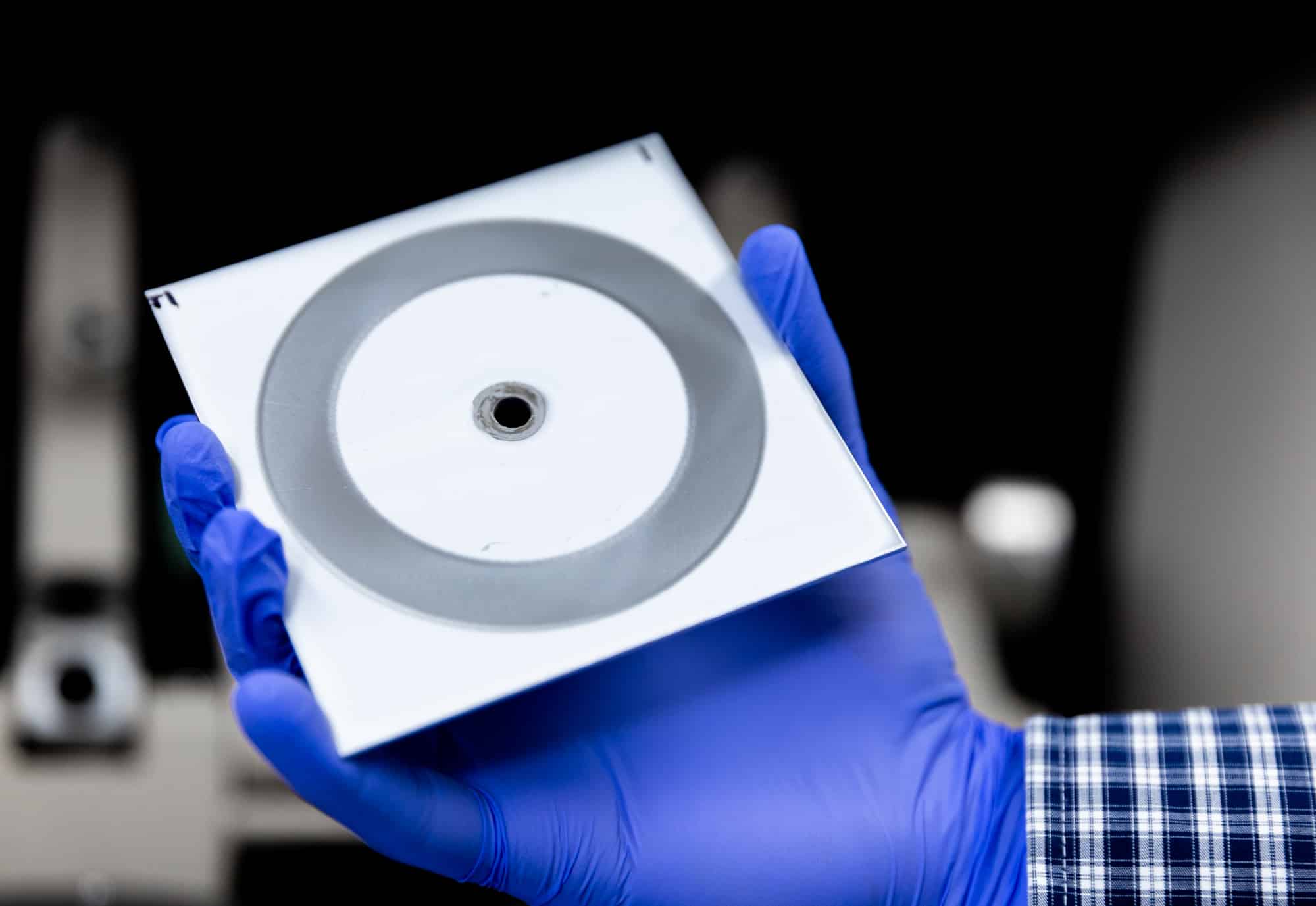

- Surface conditioning (activation): A titanium-phosphate colloid primes the steel with nuclei to produce a fine, uniform crystal during phosphating—key to paint performance.

- Zinc phosphating (spray or immersion): Phosphoric acid + Zn²⁺ with accelerators (e.g., nitrite/nitrate/chlorate) form the Zn-Fe phosphate layer; bath selection/timing controls coating weight (Type I vs. Type V vs. heavy).

- Rinse(s) and optional neutralizing/conditioning rinse to remove carry-over and refine grain.

- Post-treatment (per class/end use): Oil / rust preventive for anti-galling and short-term corrosion resistance (heavy ZnPh + oil). Primer/e-coat/powder where long-term corrosion life is required.

- Dry & inspect: Visual uniformity (gray to black), no smut or loose powder; coating weights verified by mass-gain or chemical strip; paint-stack validation via B117/GMW cycles as specified.

Notes to Specifiers

Choose the classification by end-use:

- Paint base: TT-C-490 Type I or V (weight per performance), or MIL-STD-171 with MIL-DTL-16232 Type Z, Class 2 for paint base.

- Lubricity/anti-galling: MIL-DTL-16232 Type Z, Class 1 (with preservative oil) or consider manganese phosphate when wear is severe.

Hex-Cr policy: MIL-DTL-16232H discourages hex-chrome materials on finished items unless drawings/contracts require them; TT-C-490 provides Cr⁶⁺-free organic/inorganic pretreat options (Types III/IV).

Don’t confuse designations: Class 1A

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Looking for coatings that work as hard as you do?.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.