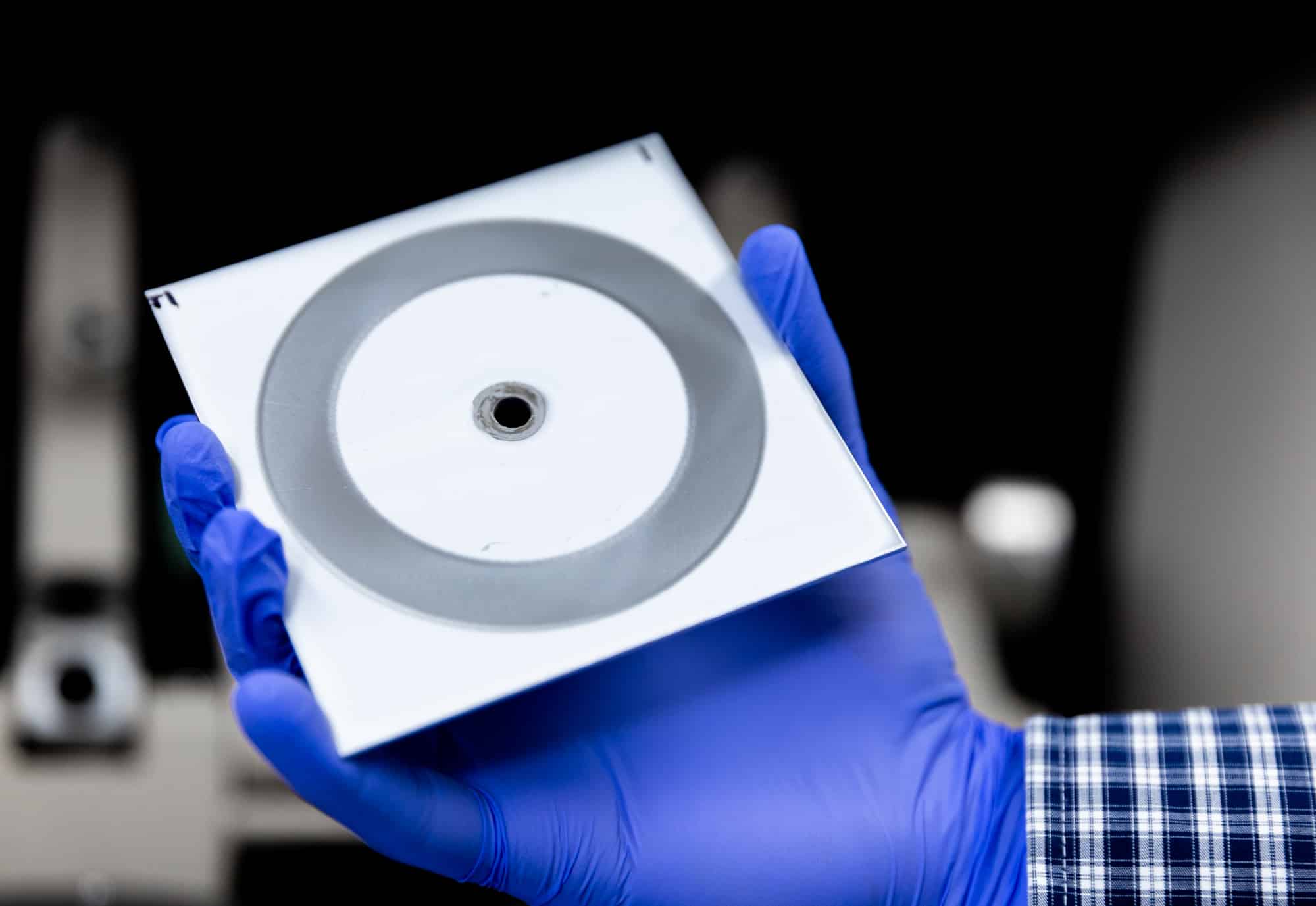

Zinc Nickel Alloy Plating

A Sacrificial Coating for Corrosion Resistance

Armoloy’s Zinc Nickel Surface Solution

The Armoloy Corporation helps global manufacturers protect their most valuable, high-precision components with a broad spectrum of engineered coating technologies.

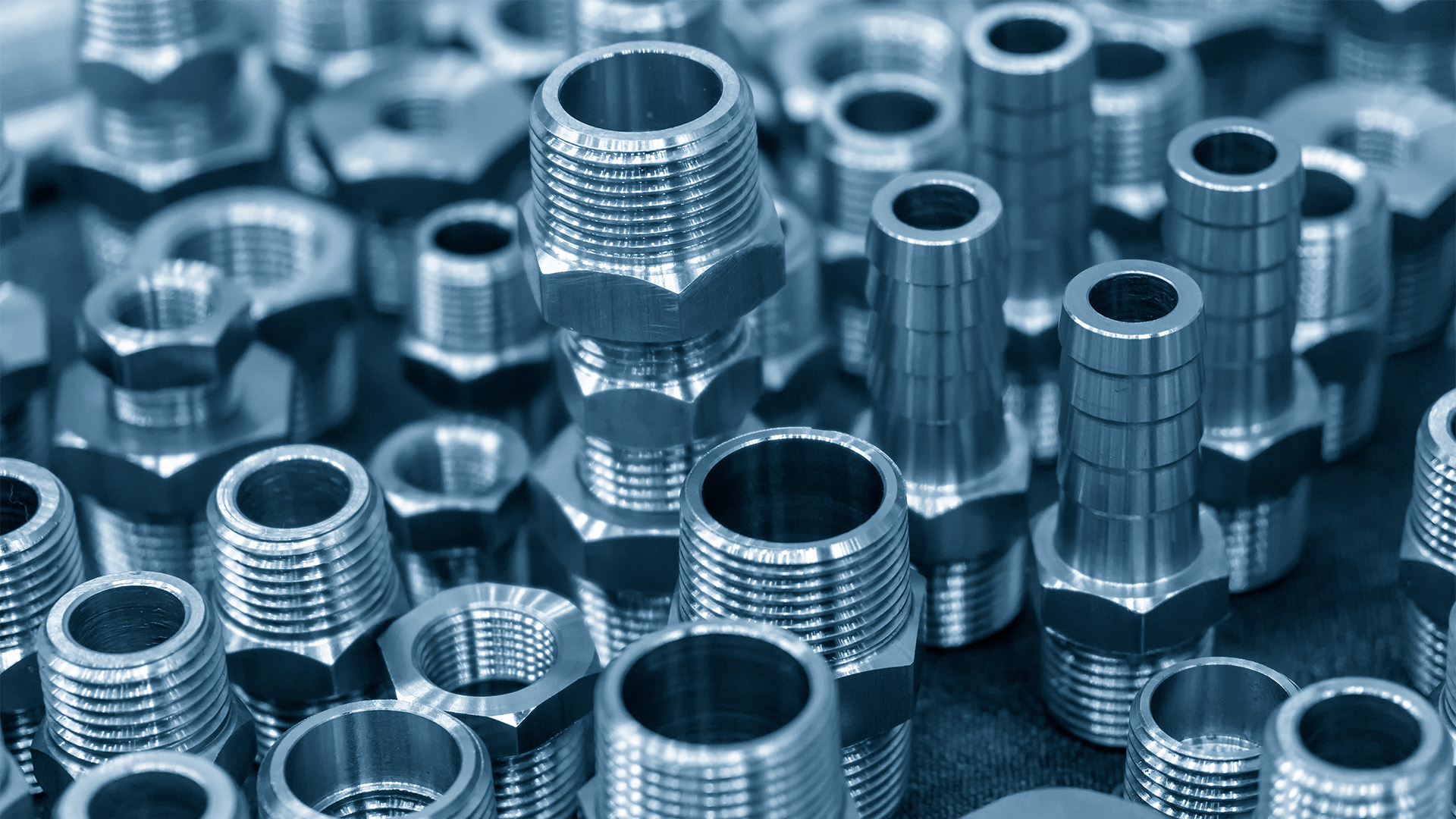

One of the key advantages of zinc-nickel plating is its ability to create a uniform and smooth coating that offers enhanced wear resistance and ductility, making it suitable for components subject to constant stress, such as brake calipers, fasteners, and landing gear components. The coating also helps in reducing maintenance costs and extending the life of critical parts, which is particularly valuable in applications requiring long-term durability, such as in automotive engine compartments and electrical transmission equipment.

Zinc Nickel Alloy Plating Highlights

- Deposits are bright and burn-free, even at high current densities

- Deposits do not display whickers when bent after plating

- Excellent covering power and uniformity of plate distribution

- Suitable for either rack of barrel plating

- Deposits offer exceptional corrosion protection, even after thermal shock

- Resists Hydrogen Embrittlement

Proven applications

- Fasteners

- Marine structures

- Disk breaks

- Connectors & brackets

- Electronics

- Batteries

- ROHS and REACH Compliant

- GMW-4700

Zinc Nickel Plating

Features & Benefits

Corrosion resistance

Provides exceptional protection against rust, especially in saline environments, which prolongs the lifespan of metal parts

Low coefficient of friction

Reduces wear and tear on moving parts, which is crucial for components like gears and shafts

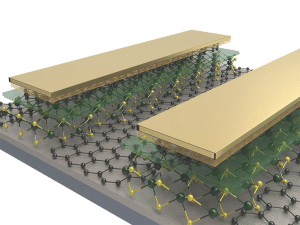

Excellent adhesion for coatings

Offers a great surface for subsequent coatings or paints, enhancing overall durability and aesthetic

Outperforms standard zinc plating

Provides greater corrosion resistance over standard zinc plating and is an excellent cadmium replacement

Galvanic corrosion Prevention

Acts as a sacrificial coating to protect base metals from corrosion in electrochemical environments

Consistent Torque Characteristics

Repeatable COF values ensure that fastener assembly results in consistent, reliable bolted joints every time

Multiple processing methods

Can be rack or barrel plated depending on job size and specifications

Performs under pressure

Helps guarantee the safety of highly stressed components

The Science Behind Zinc Nickel Plating

Zinc nickel alloy plating typically consists of 10-15% nickel with the remainder being zinc. This surface solution is known for its exceptional corrosion resistance, often performing up to five times better than standard zinc plating. It also provides excellent protection in harsh environments, including those with high temperatures and abrasive conditions, making it a popular choice in the automotive, aerospace, defense, and construction industries.

Zinc-nickel plating can be applied using either alkaline or acid processes, each with its own set of advantages. The alkaline process is preferred for its uniform distribution and ductility, making it ideal for parts that undergo post-plating forming. The acid process, on the other hand, is more efficient and is often used on substrates like cast iron.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.