nickel boron nitride

A Surface Solution for High Temperature Applications

High Temperature Solutions from Armoloy

The Armoloy Corporation helps global manufacturers protect their most valuable, high-precision components with a broad spectrum of engineered surface coatings.

Nickel boron coating is primarily used in applications requiring high wear resistance and thermal stability. This includes plastic injection molds, automotive components, aerospace parts, and industrial machinery. It is especially beneficial for components like core and cavity blocks, lifters, and ejector pins in molding industries, where it significantly enhances the release properties and wear life.

Nickel Boron Nitride Highlights

- Excellent corrosion resistance

- Improved wear resistance

- PFOS, PFOA, PFAS free

- Silver high satin appearance

- Enhanced lubricity

- Chemically resistant

Proven applications

Applying Armoloy’s nickel boron coating can improve the long-term performance of applications within the following industries, as well as many others:

- Injection Molding

- Automotive

- Aerospace

- Automated machinery

- Bearings

- Specialized components

Certifications

- AMS 2438

- AMS 2402

- ASTM B733

- AMS-C-26074

- MIL-C-26074

- MILDTL-32119

Performance Characteristics

Nickel Boron Nitride by the Numbers

- Wear TWI 8 mg/1000 cycles

- Up to 92Rc particle hardness

- +1000 hrs Salt Spray

- Friction Coefficient as low as .13

- Deposit range from 0.0002"-0.002"

- Withstands temperatures up to 1562°F (850°C)

Nickel Boron Nitride

Features & Benefits

High-temperature stability

Withstands temperatures up to 1562°F, suitable for high-heat environments

Improve lubricity

Offers low friction properties, minimizing wear and energy consumption

Chemical resistance

Protects against harsh chemicals, preventing corrosion and damage

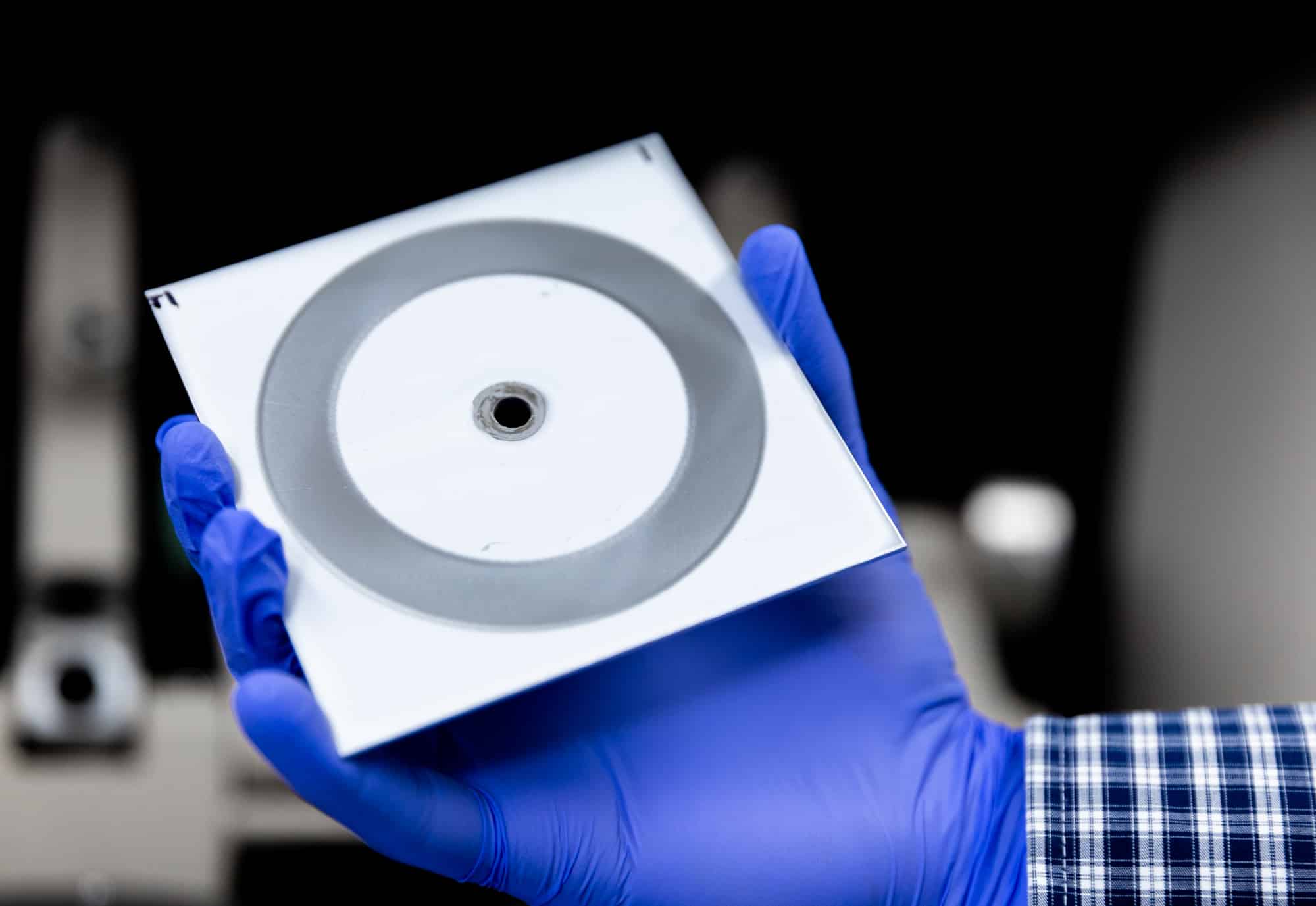

Aesthetic finish

Provides a uniform, attractive satin silver appearance that does not alter component dimensions

Enhanced wear resistance

Enhances the durability and lifespan of components

Environmental resistance

Resistant to a variety of environmental factors which makes NiBN coatings suitable for use in challenging external conditions

Environmental benefits

Armoloy NiBN coating is PFOS, PFOA, and PFAS free

Uniform coating

Provides a uniform deposit, ensuring even coverage and protection across all surfaces

The Science Behind Nickel Boron Coating

The nickel boron nitride (NBN) plating process, often referred to as electroless nickel boron (EN-BN) plating, is a highly advanced and technical method for applying a protective coating to various substrates. This process is autocatalytic, meaning it does not require an electrical current to deposit the nickel boron alloy onto the surface of a part. Instead, it utilizes a chemical reaction to achieve deposition. The solution used for NBN plating typically contains nickel ions and a boron-containing agent like sodium borohydride or an alkylamineborane, along with other chemicals such as buffers and complex agents to control the plating process.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.