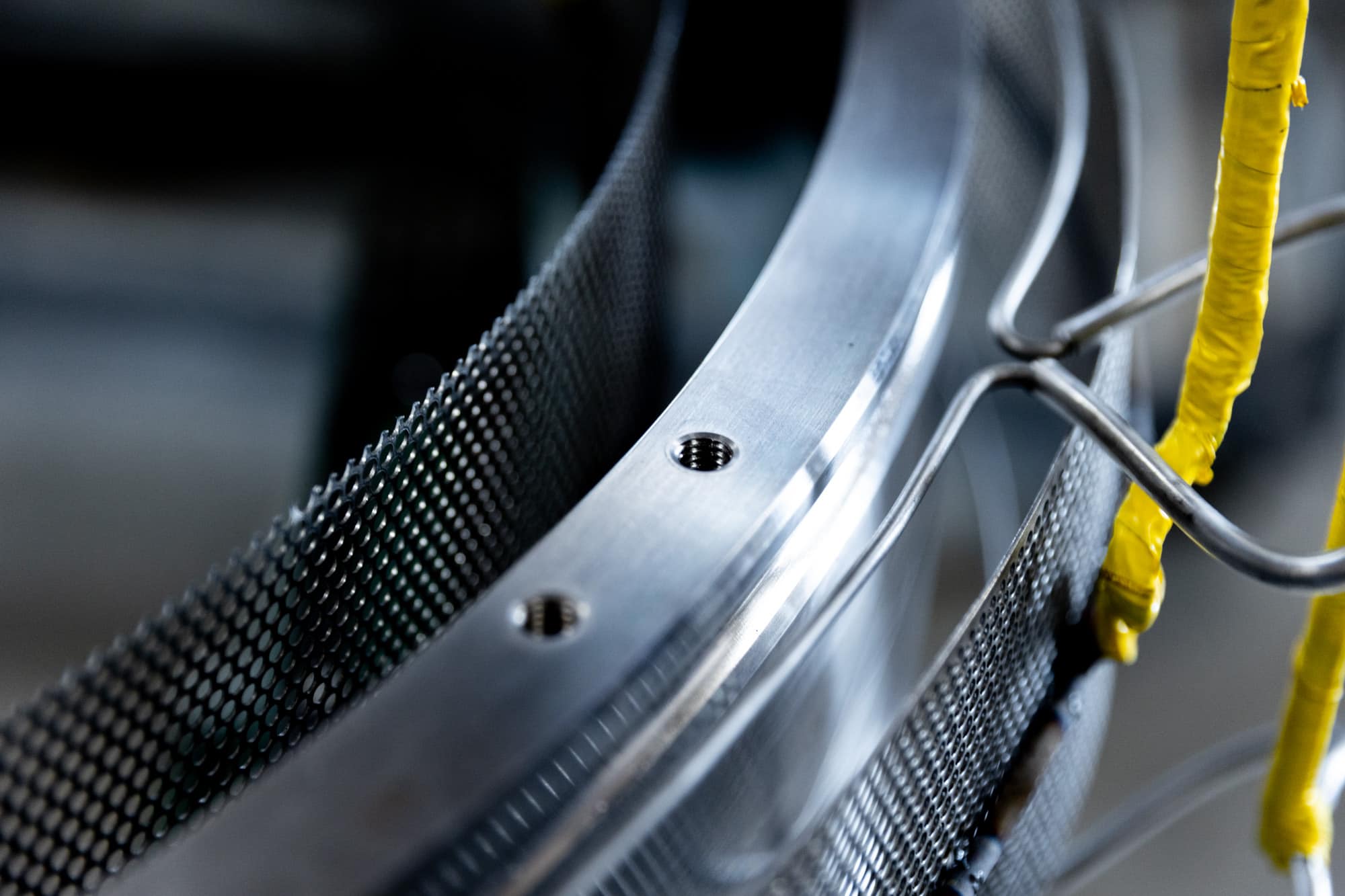

Proven Stainless Steel Protection

Increase the longevity of your stainless steel materials

Nitric Passivation Highlights

- Improves base substrates corrosion resistance

- Uniform, smooth appearance, finish, and cleanliness

- Deburring of polished surfaces

- Improved and extended product life

- Improved aesthetics

- No physical or dimensional changes

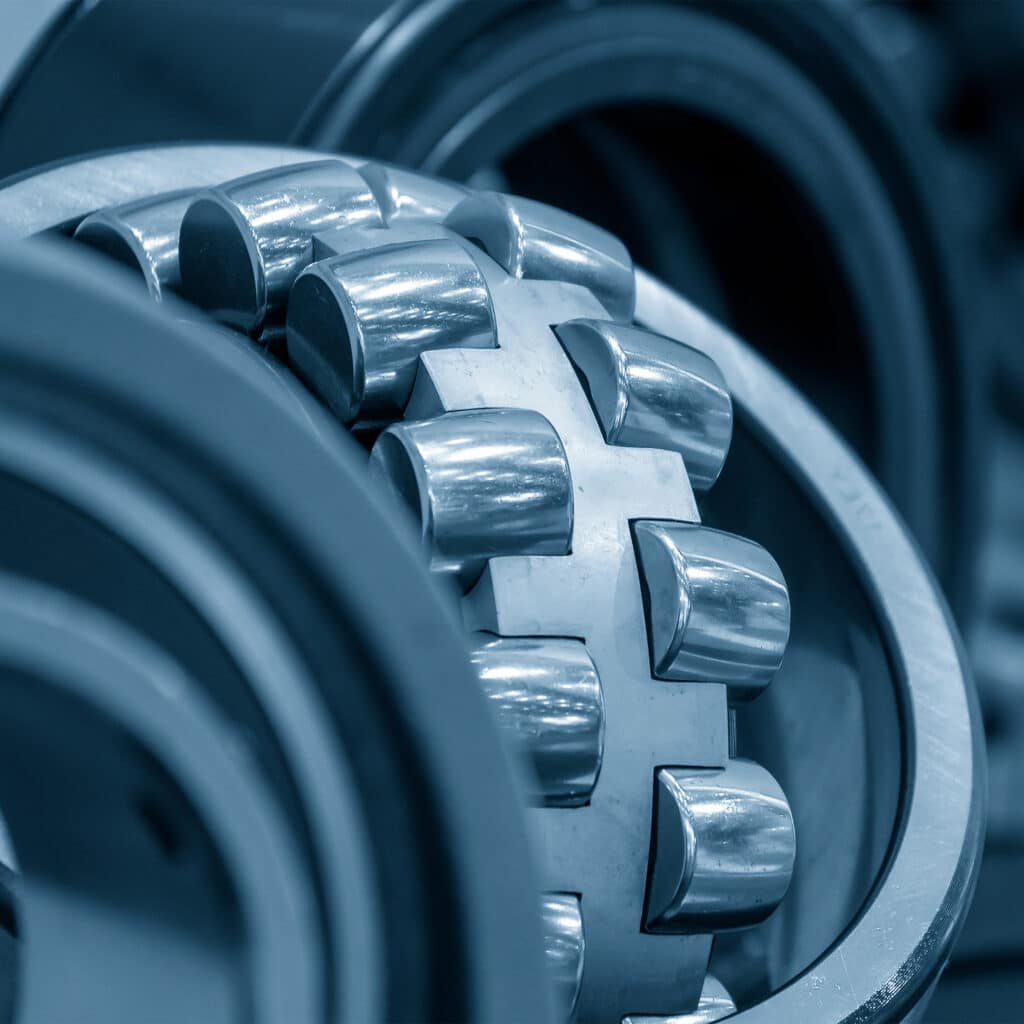

Proven Applications

Utilizing nitric passivation can improve the long-term performance of applications in all the following industries:

- Food & Beverage

- Medical

- Aerospace

- Semiconductor

- Military

- Automation

Certifications & Specifications

- AMS QQ-P-35 (Type VI)

- ASTM A967-05 (Nitric II)

- Sikorsky SS 8435 Rev. 8

- MIL-S-5002D (Amend 2)

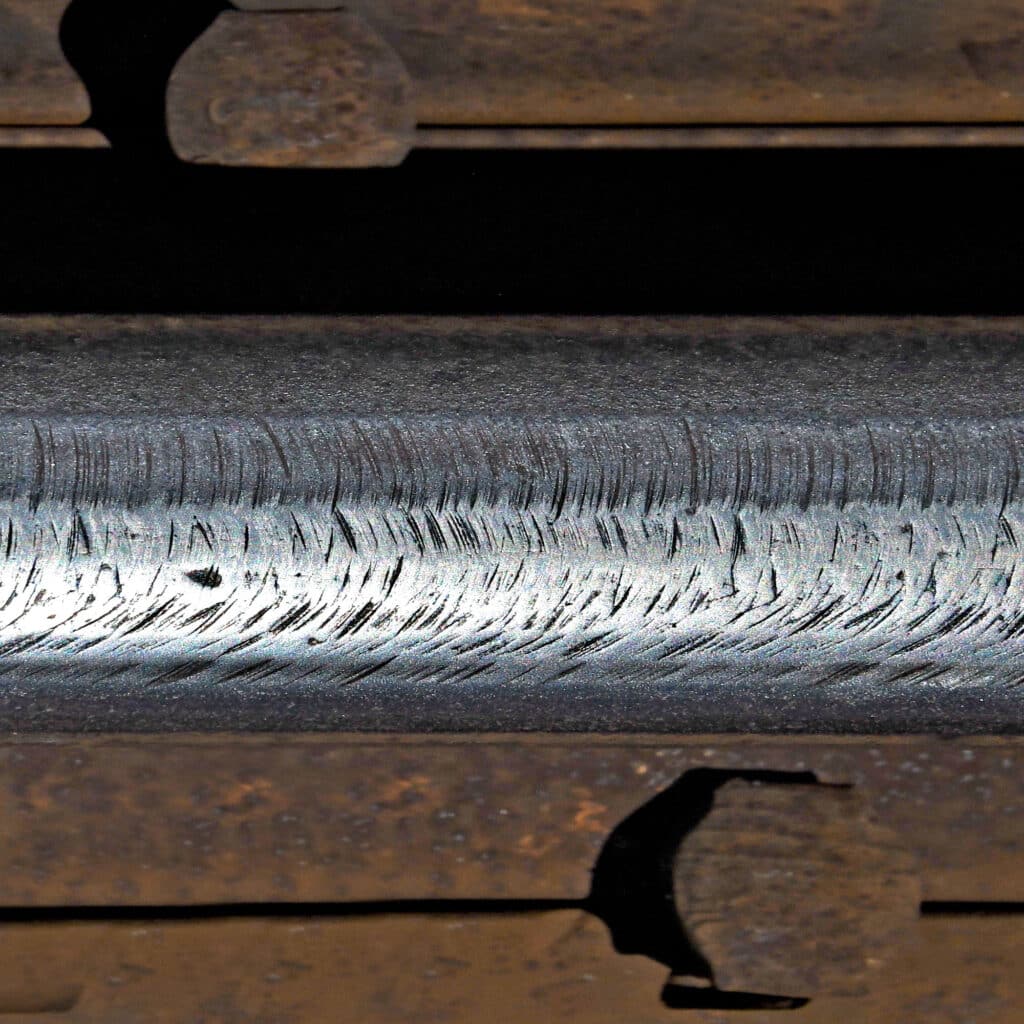

How Nitric Passivation Works

Nitric passivation is a well-established method for protecting stainless steel from rust and corrosion caused by oxidation.

By putting stainless steel into an acid bath, Armoloy’s experts can help dissolve any of the free iron on the surface while maintaining the chromium properties. The stainless steel then gets exposed to air and oxygen, which forms a chromic oxide layer that’s more protective and prevent corrosive materials from getting into the surface.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Improve metal surface performance to its highest pinnacle. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.