passivation

Put Metal Corrosion in the Past

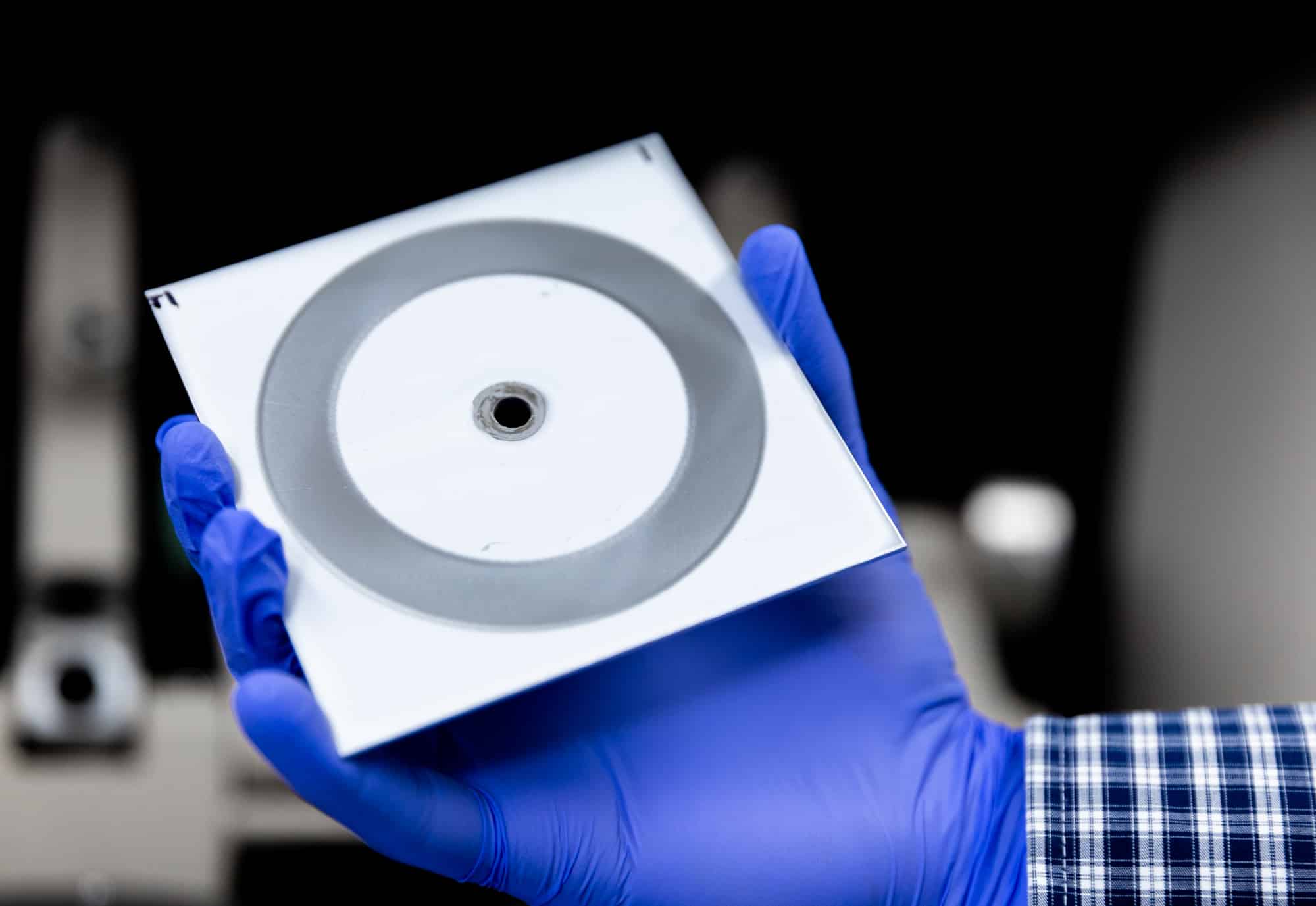

Armoloy Citric Passivation Highlights

- Natural process using citric passivation

- Environmentally friendly

- Restores natural chromium oxide layer

- Maximizes the corrosion resistance for most stainless steels (including all 300/400 series SS)

- Removes free iron particles

Proven applications

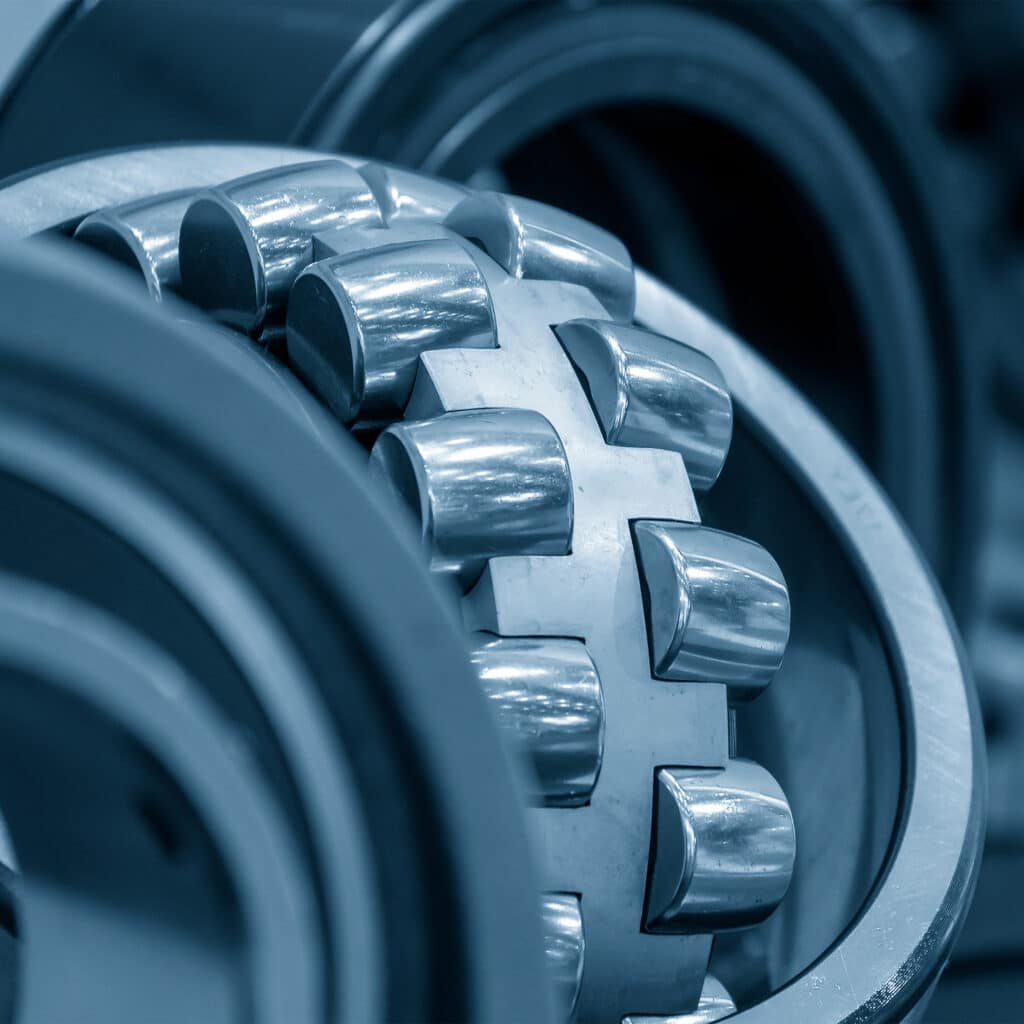

Utilizing citric passivation can improve the long-term performance of applications in all the following industries.

- Food & Beverage

- Medical

- Aerospace

- Semiconductor

- Military

Certifications

- AMS 2700

- ASTM A380

- ASTM A967

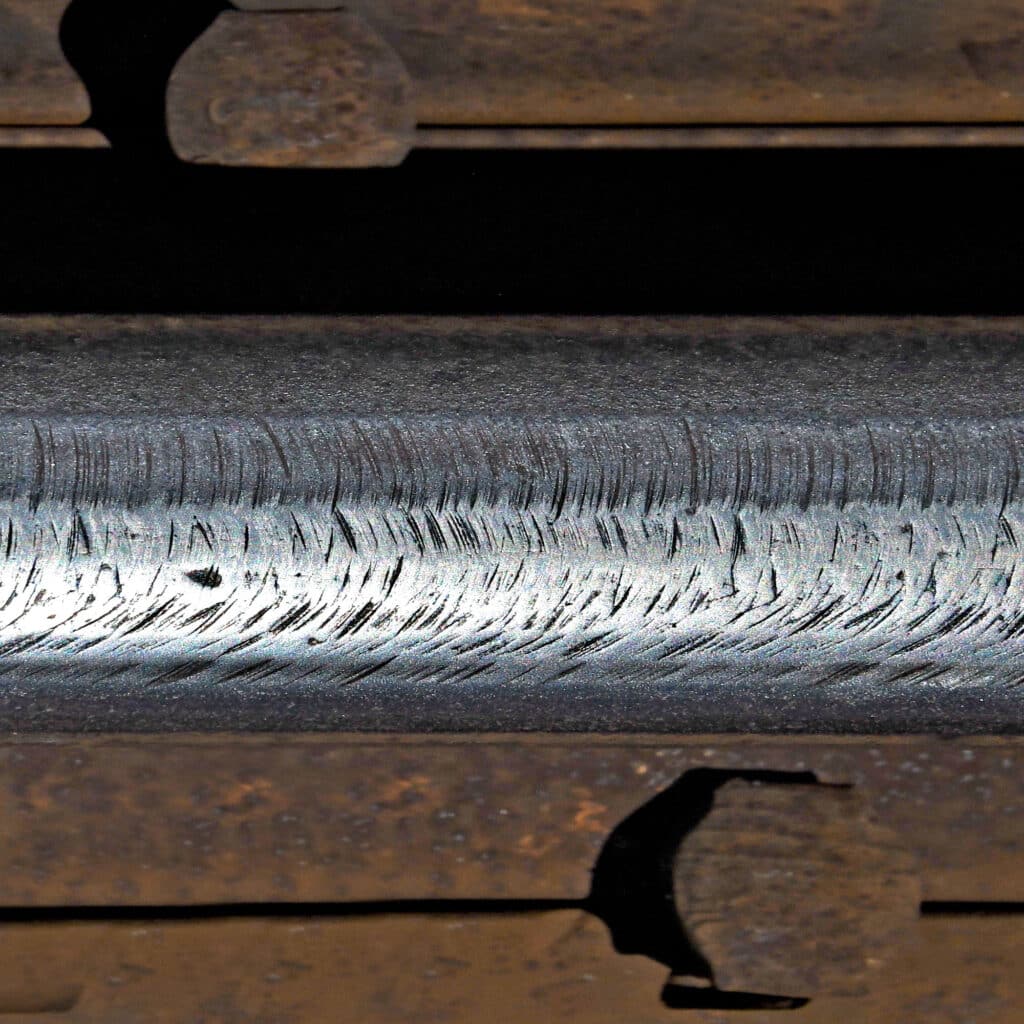

The Science Behind Citric Passivation

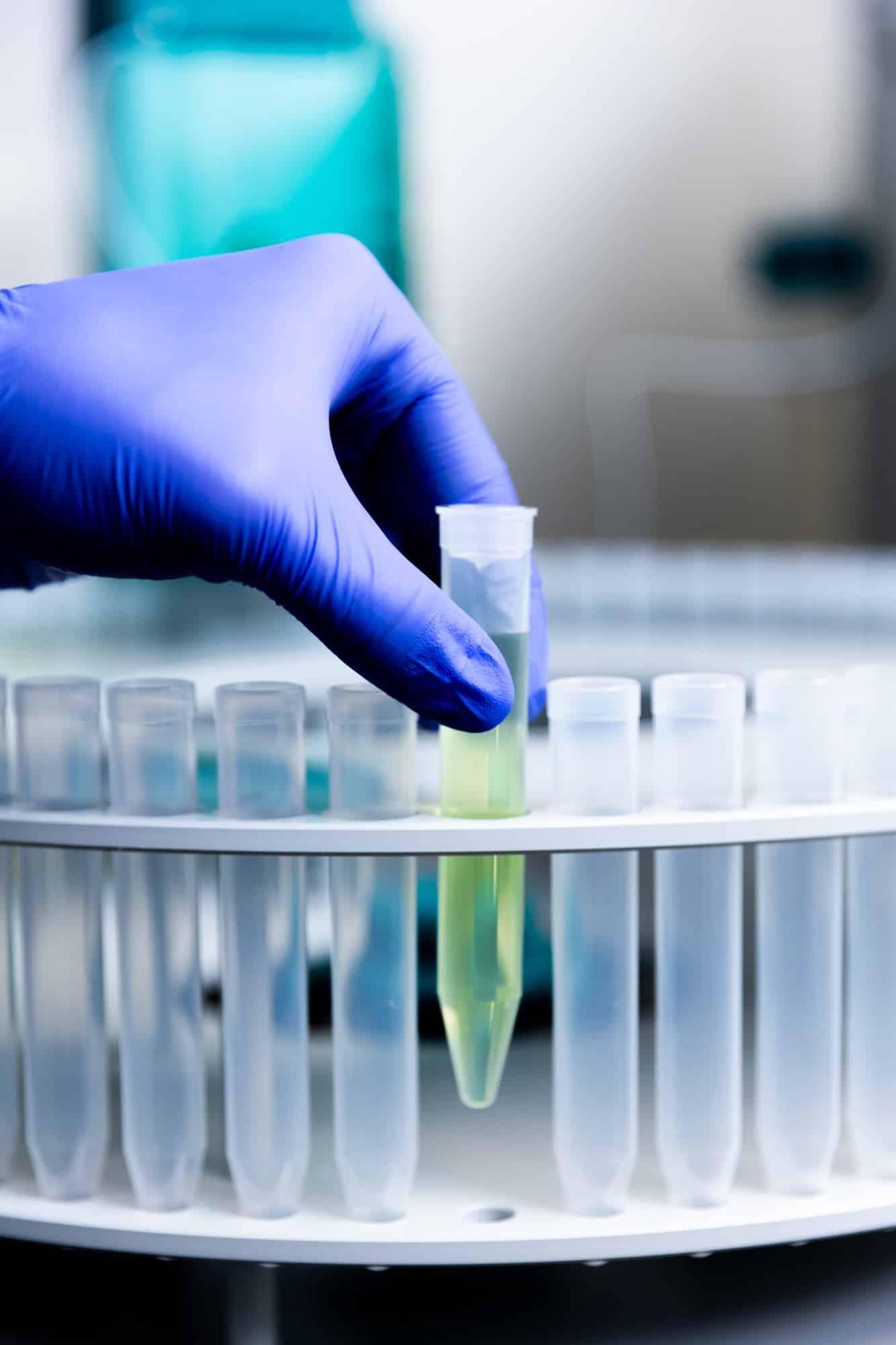

While high chrome content makes stainless steel naturally corrosion-resistant, it does not prevent harmful contaminants from breaching its surface. As a non-electrolytic finishing process, citric acid passivation removes free iron particles and other surface contaminants from the material’s surface resulting from manufacturing processes, creating a passive oxide layer that maximizes corrosion resistance.

Not only highly effective, citric passivation offers the versatility to provide this same effect for nearly all stainless and high chromium steels. But what makes citric passivation a superior alternative to nitric passivation lies in its process. The citric acid used during passivation is not only much safer, but is also organic, non-hazardous, and ensures no toxic fume emissions.

Because of its environmental benefits and effectiveness compared to nitric passivation—confirmed through multiple studies—industry manufacturers around the world turn to Armoloy for our citric passivation capabilities. Our team offers the capability of providing innovative solutions customized to the requirements of both your application and industry.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Eliminate metal wear and friction from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.