Rolling contact fatigue (RCF) is caused by the repetitive stress cycles experienced by materials in rolling contact applications, such as bearings, gears, and rail-wheel interfaces. The primary factors contributing to RCF are:

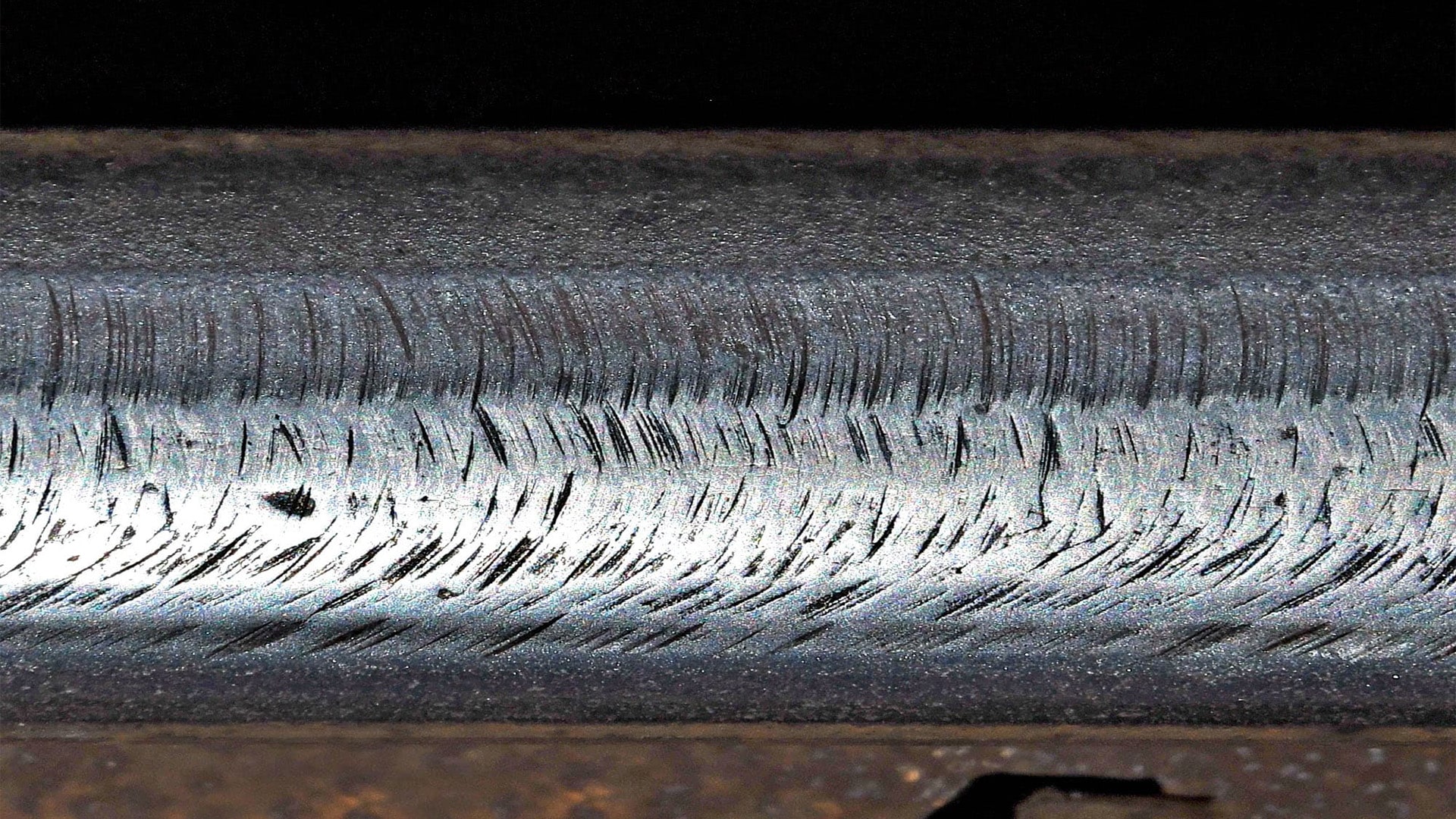

- Cyclic Stress: Continuous rolling motion generates alternating compressive and tensile stresses at the contact points, leading to the initiation and propagation of cracks.

- High Load: Increased loads on the rolling elements result in higher contact stresses, accelerating fatigue damage.

- Material Defects: Inherent material defects, such as inclusions, voids, or microstructural anomalies, act as stress concentrators and initiate crack formation.

- Surface Roughness: Surface irregularities and roughness can amplify stress concentrations, leading to premature fatigue failure.

- Lubrication: Inadequate or improper lubrication results in higher friction and surface damage, increasing the likelihood of RCF.

- Contaminants: Presence of foreign particles or debris in the contact zone can cause surface indentation and initiate fatigue cracks.

Preventive Measures:

- Material Selection: Use of high-quality, fatigue-resistant materials.

- Surface Treatments: Applying surface hardening techniques such as carburizing or nitriding to improve resistance to RCF.

- Proper Lubrication: Ensuring adequate lubrication to reduce friction and wear.

- Regular Maintenance: Conducting routine inspections and maintenance to identify and address early signs of RCF.

By addressing these factors, the incidence of rolling contact fatigue can be minimized, thereby extending the operational life of rolling contact components.