A classic example of cavitation occurs in ship propellers.

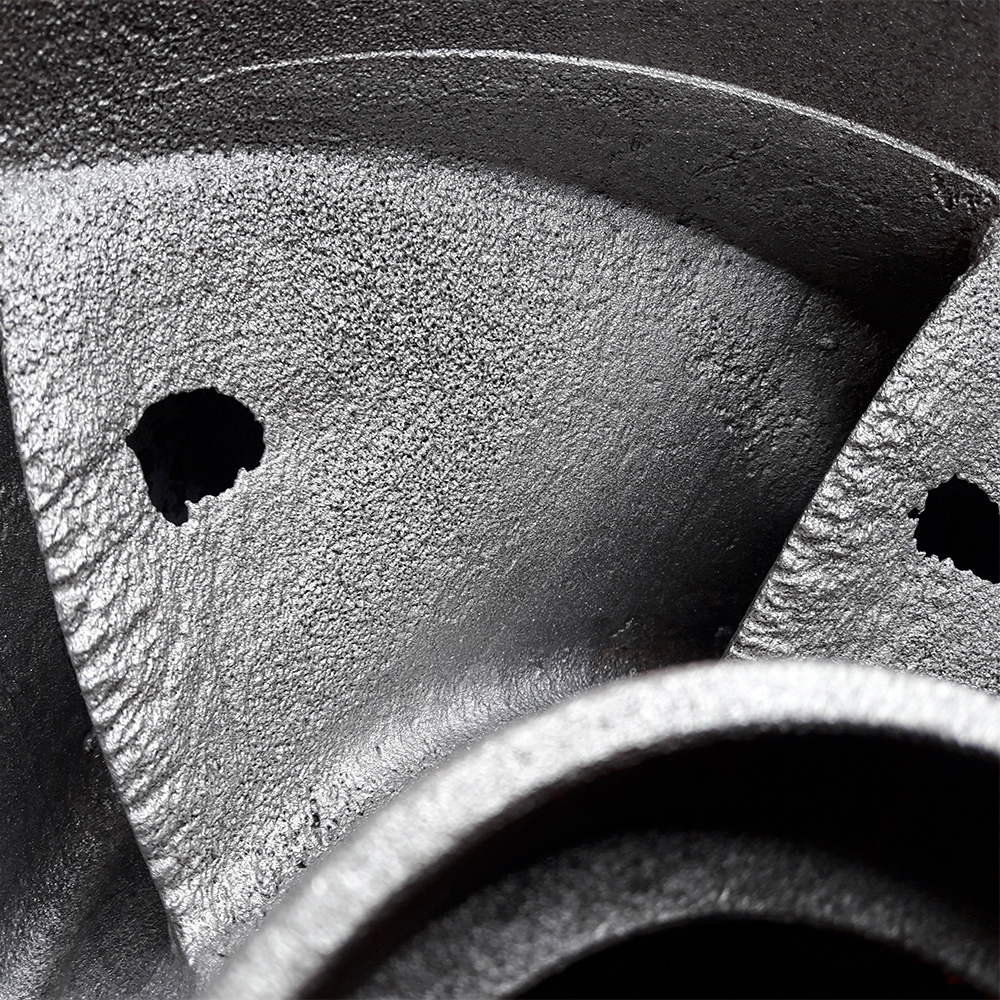

When a ship’s propeller spins at high speeds, it can create areas of low pressure in the water. In these low-pressure zones, water vaporizes, forming tiny bubbles. As the bubbles travel into areas of higher pressure, they collapse or implode, releasing a significant amount of energy. This implosion can cause pitting and erosion on the propeller surface, reducing its efficiency and potentially leading to damage over time.

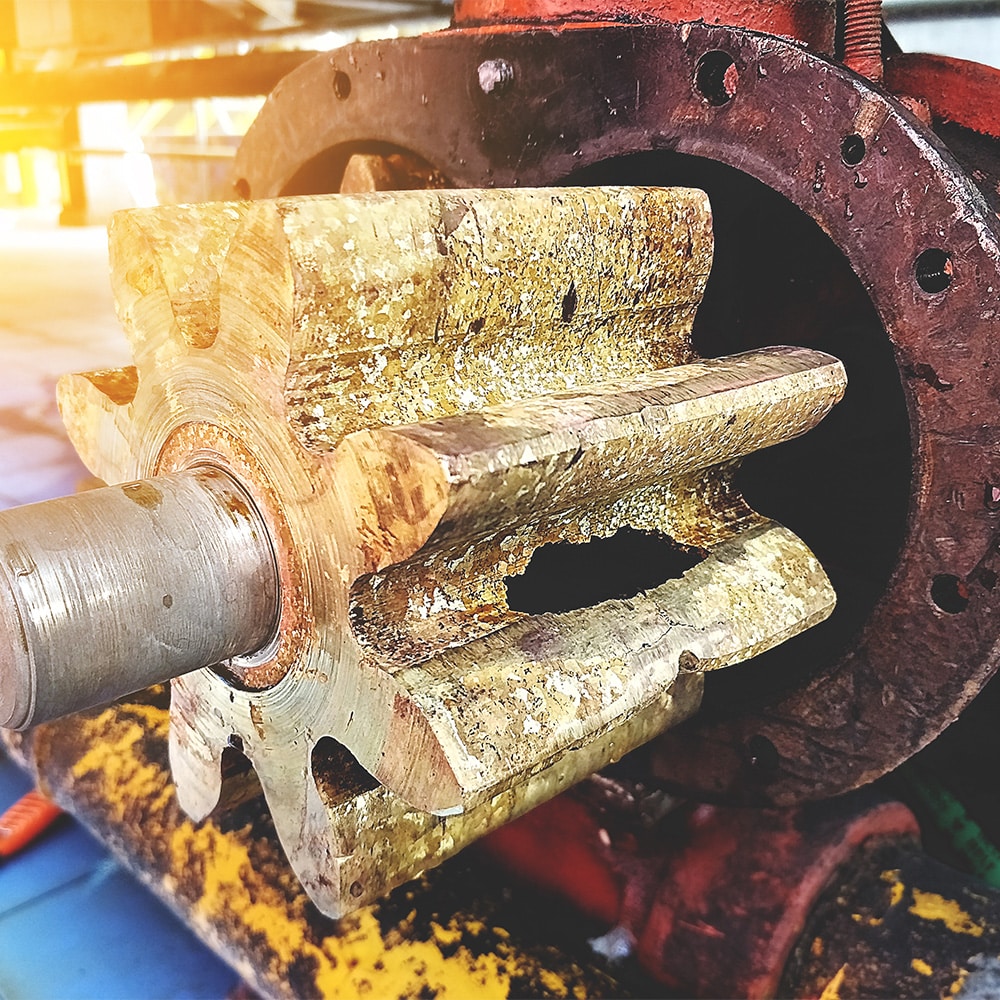

Cavitation can also happen in pumps, turbines, and other fluid-moving machinery, where similar pressure changes cause bubble formation and collapse.