Armoloy Copper Plating

Increase Conductivity and Improve Corrosion Control

Armoloy’s Copper Plating Solution

Armoloy helps global manufacturers protect high-precision components with a broad spectrum of engineered plating technologies.

Copper features a distinctive reddish-orange metallic color and plays a crucial role in many plating processes. It’s commonly utilized as a strike layer and is increasingly used for its excellent adhesion qualities on various substrates, making it an ideal underplate. This makes copper essential in scenarios where strong adhesion is necessary for subsequent layers of different materials. Additionally, copper’s outstanding thermal and electrical conductivity makes it valuable in a range of applications, including heating, industrial, and electrical sectors.

Copper Plating Highlights

- Excellent conductivity

- Absolute adhesion

- Enhanced corrosion resistance

- Malleable

- Aesthetic qualities

- Antibacterial properties

Proven Applications

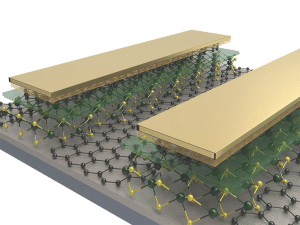

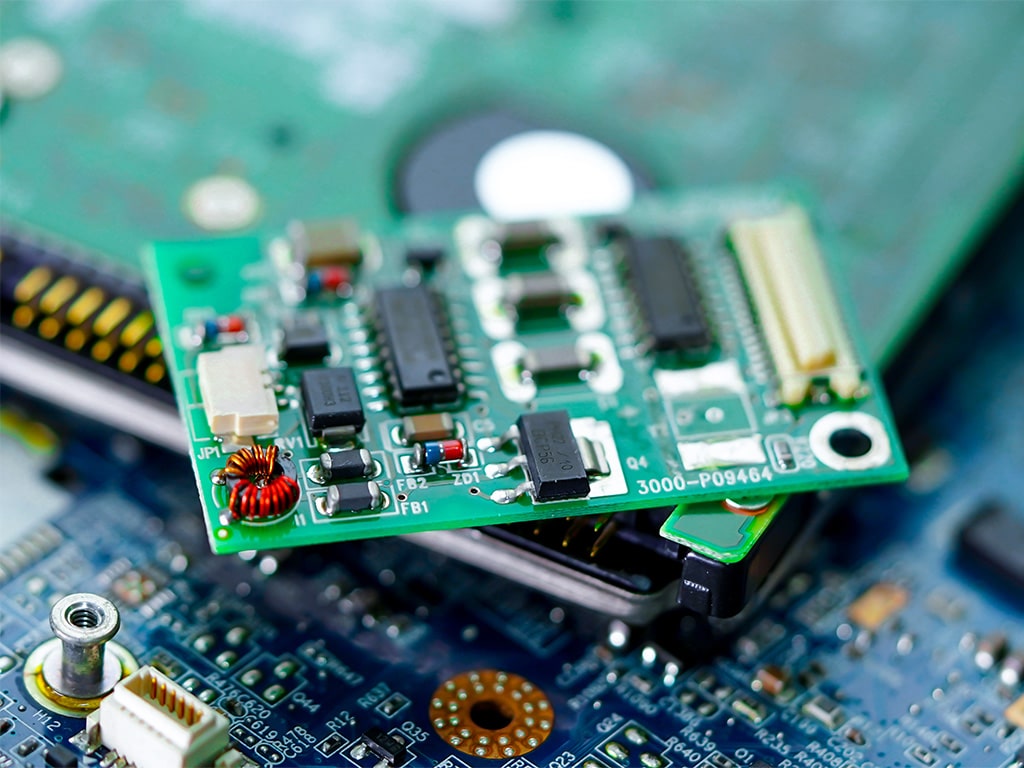

- Circuit boards

- Automotive

- Marine structures

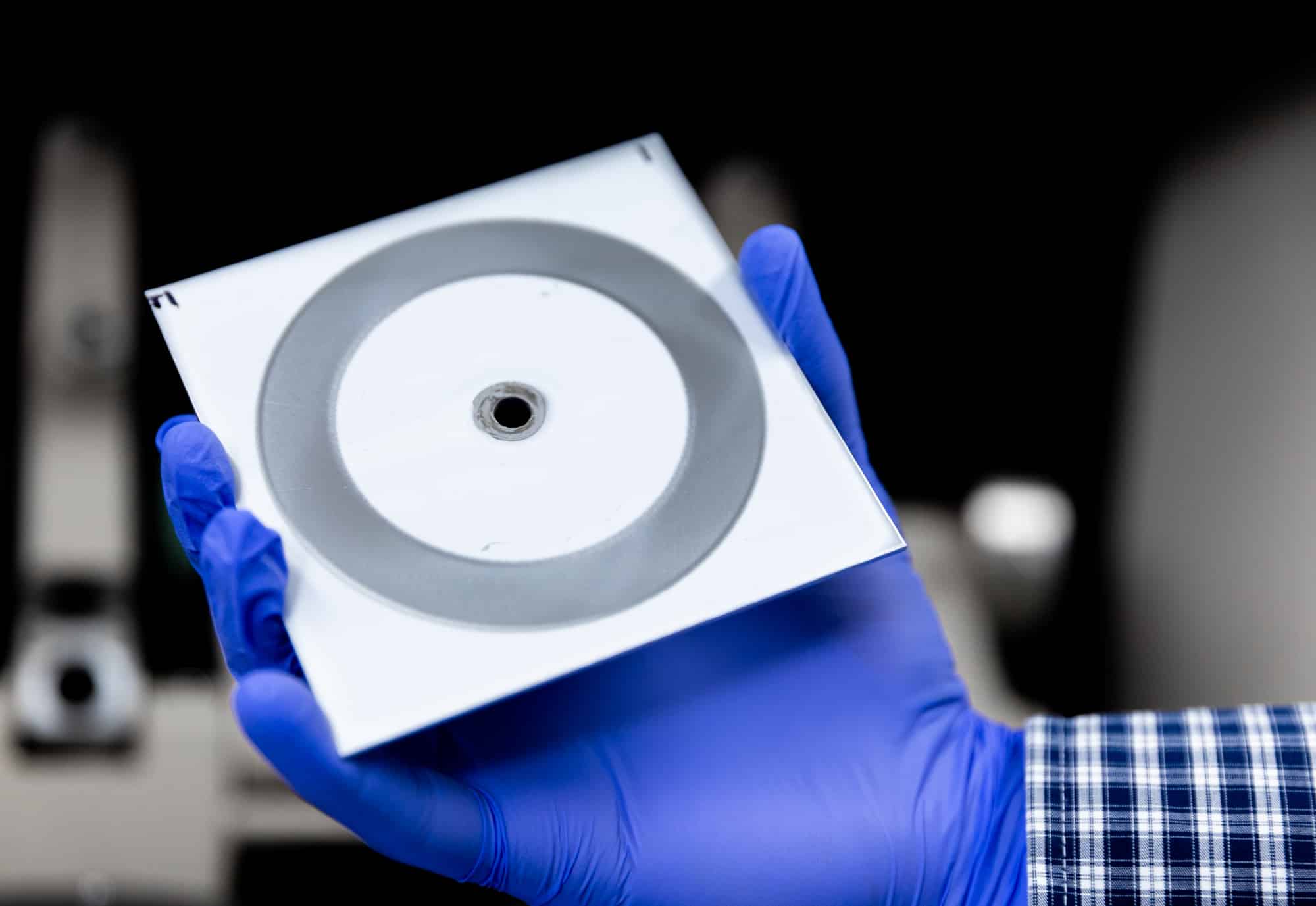

- Semiconductors

- Electrical wiring

- Industrial machinery

- EMI/RFI Shielding

- Medical devices

- Telecommunications

Certifications

- AMS 2418 Rev. H

- MIL-C-14550

- ASTM B734

- Most company specifications

Performance Characteristics

Copper Plating by the Numbers

- 99.9% pure copper strike

- Thickness up to 0.020" per side

- High temp bake up to 750°F (399°C)

- 0.0001" minimum deposit

Copper Plating

Features & Benefits

Excellent conductivity

Ideal for use in electrical and electronic components. The high conductivity is essential for manufacturing components that require efficient energy transfer

Good adhesion

Copper adheres well to a variety of substrates, providing a stable base layer for additional coatings. This characteristic ensures that subsequent layers of plating adhere better, which is particularly important in complex multi-layer plating processes

Enhanced corrosion resistance

While copper itself provides decent corrosion protection, it often serves as an undercoat for more corrosion-resistant metals like nickel, enhancing the overall durability of the coating against environmental factors

Malleability

Copper’s softness allows it to be easily shaped and molded without cracking, which is advantageous during the manufacturing of intricate parts

Cost Effectiveness

Compared to other metals like gold and platinum, copper is relatively inexpensive and widely available, making it a cost-effective option for plating needs

Aesthetic Qualities

Copper plating can be used to achieve a range of finishes, from matte to bright, adding decorative value to items such as jewelry and other consumer goods

Antimicrobial

Copper has inherent antibacterial capabilities, which make it suitable for medical and laboratory equipment where hygiene is crucial

Thermal conductivity

Apart from electrical conductivity, copper also efficiently conducts heat, which is beneficial in applications such as heat sinks and thermal management systems

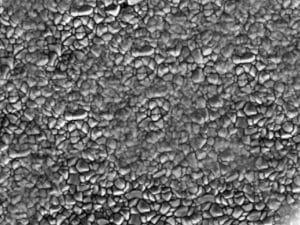

The Science Behind Copper Plating

How it Works

The copper electroplating process begins with the meticulous cleaning of the base material to prevent any imperfections. Following this, an electrolyte solution containing copper salts is used. The item to be plated acts as the cathode, and copper anodes are used. When an electric current is passed through the solution, copper ions are transferred from the anode to the cathode, effectively coating the base metal with a layer of copper. This setup allows for precise control over the thickness and uniformity of the copper layer, tailored to specific industry needs.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.