Armoloy Coatings

What is Hard Chrome Plating?

Types of Chrome Coatings

Engineering (hard) chromium vs. decorative chromium

Functional hard chrome is designed for wear and dimensional control (often thick, then ground). Decorative chromium is thin and primarily cosmetic, typically over nickel systems.

Deposit structures used in engineering chrome (per ISO 6158)

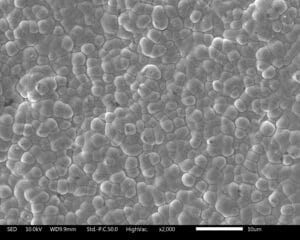

- Micr-cracked chromium (typical hard chrome).

- Micro-porous chromium (often produced by special treatments to hold lubricant).

- Crack-free/ specially profiled deposits for barrier performance or tight fits.

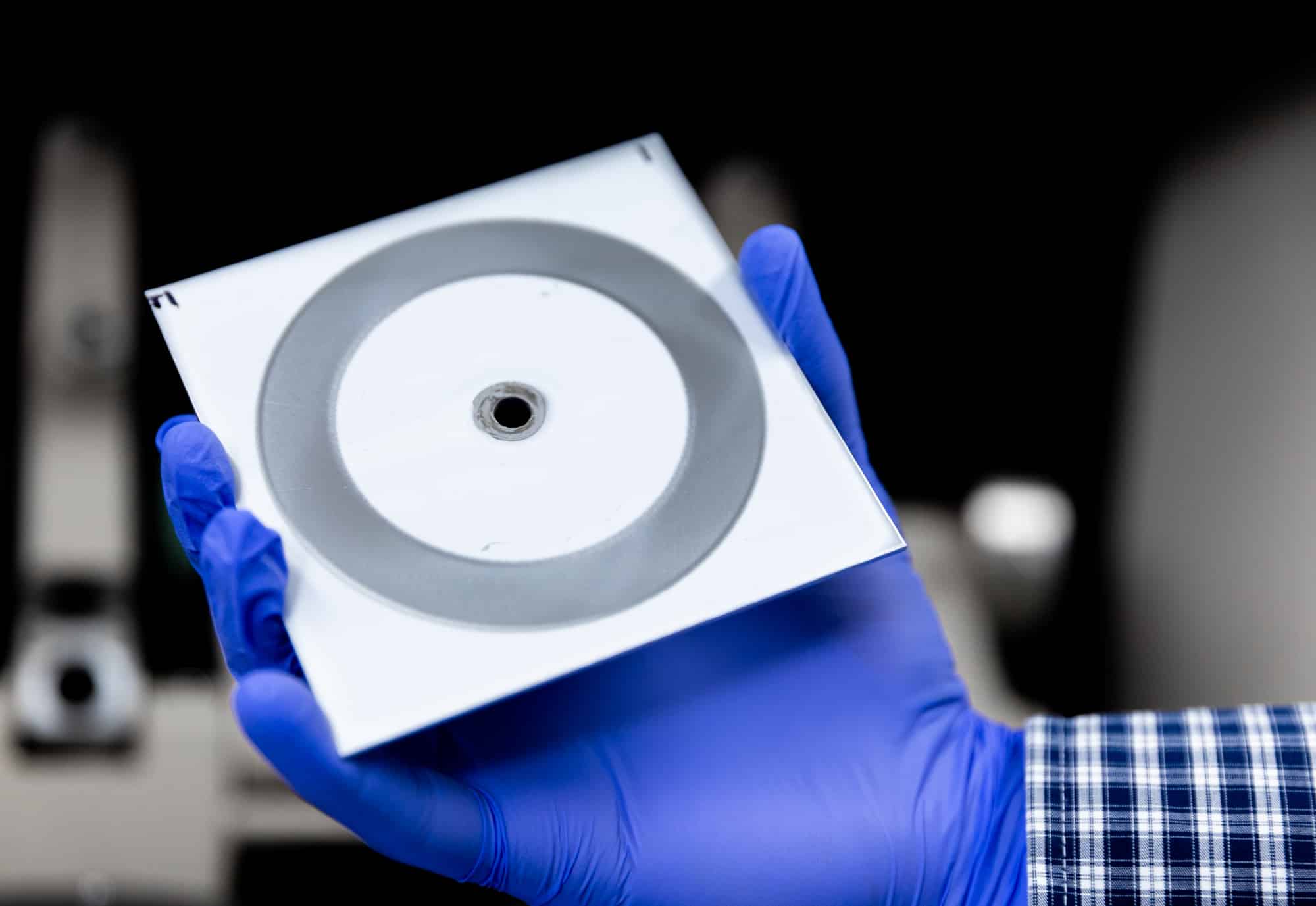

Thin Dense Chrome (TDC) variants

Very uniform, thin, and either micro-cracked or micro-nodular/crack-free depending on process—useful where tight tolerance and consistent coverage on complex shapes are critical.

Performance Characteristics

Hard Chrome by the Numbers

- Hardness: ~900–1100 HV (≈ HRC 66–70) depending on bath and process

- Typical thickness range (functional): 0.0001–0.030 in (≈ 2.5–760 μm), with many wear surfaces in the 0.0005–0.002 in range

- Coefficient of friction (against steel): about 0.21 dry and ~0.16 lubricated (application-dependent)

- Microcrack density (typical hard chrome): often on the order of hundreds of cracks per linear inch; “crack-free” or micro-nodular TDC variants are engineered to reduce/alter crack networks

- Corrosion behavior: Because hard chrome is commonly micro-cracked, barrier corrosion resistance by itself is limited; using suitable undercoats (e.g., nickel) or heavier deposits improves barrier performance

- Fatigue considerations: Conventional hard chrome can debit fatigue strength of high-strength steels; stress-relief before plating and post-plate hydrogen bake per standards—and shot peening—are widely used mitigations

- Ultra-hard metallic surface, low friction, excellent wear and scuff resistance

- Can restore undersize parts and then be ground/honed back to tolerance

- Works on OD/ID geometries using conforming anodes and masking/fixturing

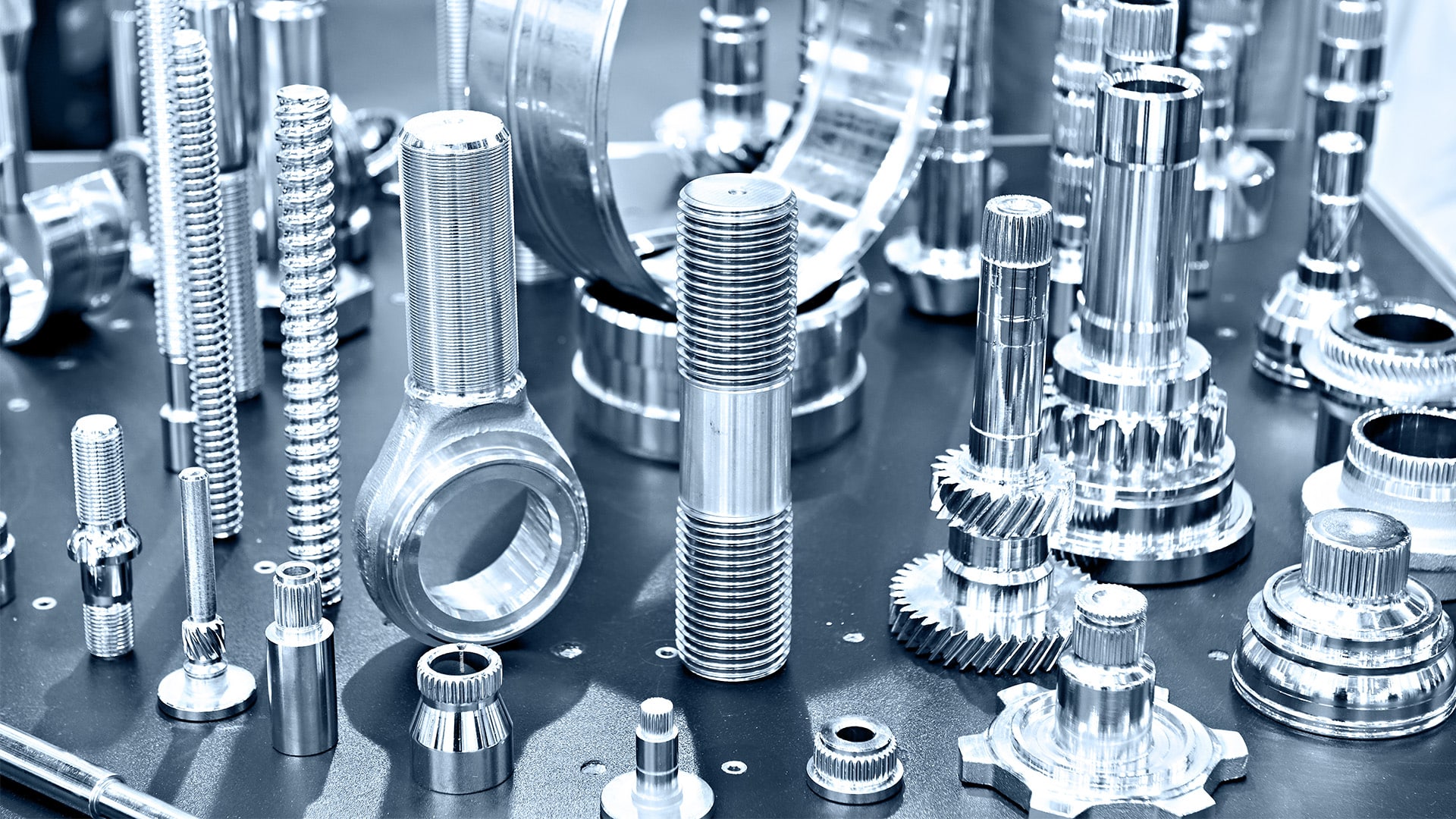

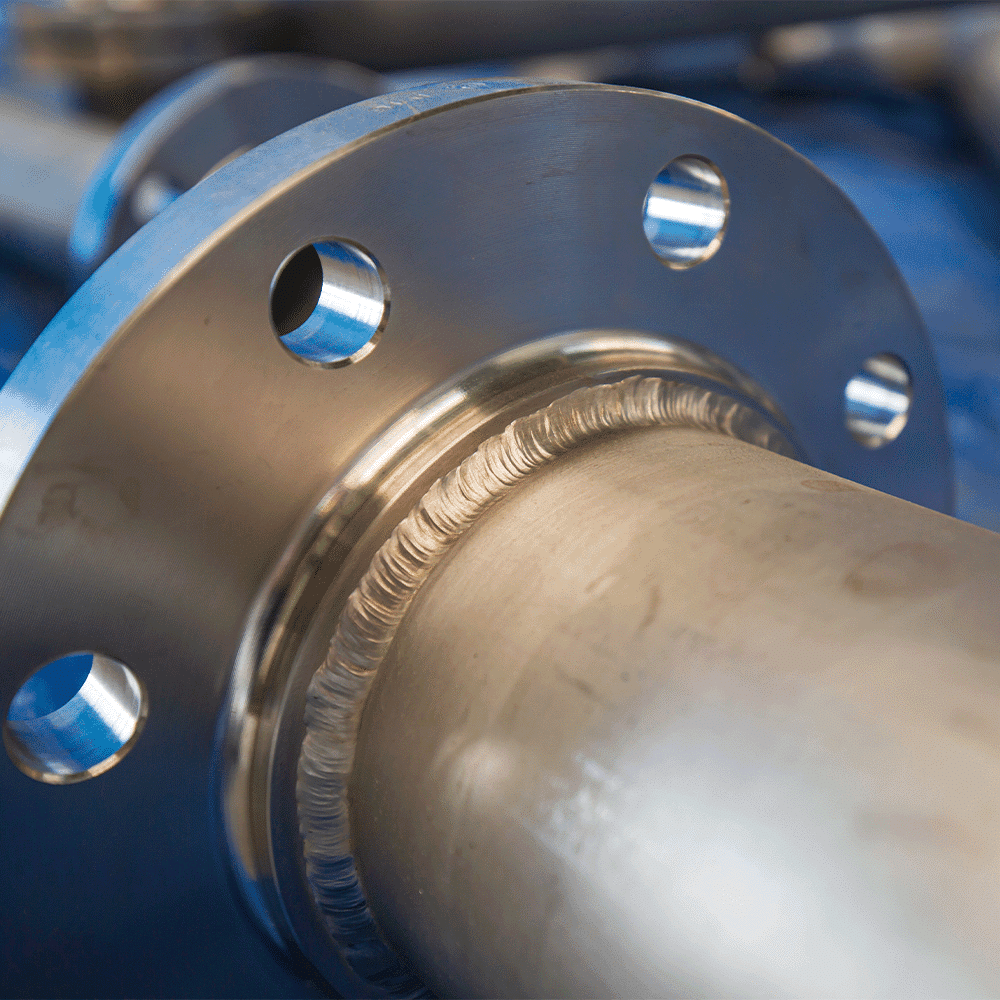

- Hydraulic rods and cylinders, piston rods, pump shafts, rolls, rams, and plungers

- Tooling: molds, dies, punches, and gauges

Hard Chrome Features & Benefits

Great wear resistance

Dense metallic chromium withstands abrasion/erosion in high-load contact conditions

Low friction + anti-galling

Reduces adhesive wear and helps parts run cooler; further lowered with lubrication or surface texturing

Dimensional restoration

Build up worn/undersize regions, then grind/hone to blueprint

Thermal + chemical durability

Metallic Cr/Cr₂O₃ surface resists many chemicals and holds up under typical service temperatures for steel components (application-specific)

Hard Chrome Plating Process

How We Chrome Plate for Quality & Repeatability

1. Pre-plate inspection & prep

Identify defects; chrome replicates and can exaggerate base metal marks. Parts may require grind/polish or weld dot-repair before plating.

2. Stress relief (pre-bake) for high-strength steels

Minimizes existing tensile stresses that, combined with plating tensile stress, can promote cracking; parameters per spec (e.g., AMS 2406 references AMS2759/9).

3. Cleaning & activation

Degrease/alkaline clean; verify water-break-free surface; reverse etch to activate.

4. Masking

Tape, lacquers, plugs, wax; shields, and robbers to control current density, coverage, and edge build-up.

5. Electroplating (chromic-acid/sulfate or alternative chemistries)

6. Rinse + post-plate hydrogen embrittlement relief

Bake high-strength steels promptly after plating per ASTM B850/customer spec; a common practice is ~375 °F (190 °C) for several hours (spec-dependent).

7. Finish to size

Grind/hone/lap to tolerance and surface finish; verify thickness and adhesion per the callout.

8. Quality & compliance

Thickness and adhesion tests per AMS/ASTM; documentation for stress-relief, bake cycles, and process control maintained to spec.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Need smooth, reliable protection? Let’s coat with precision.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.