surface engineering in new england

Electrolizing — An Armoloy Company

The Original Thin Dense Chrome

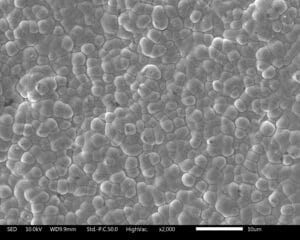

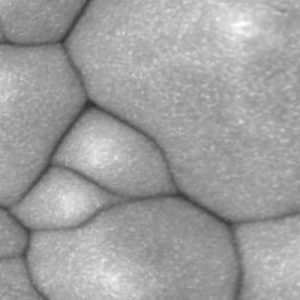

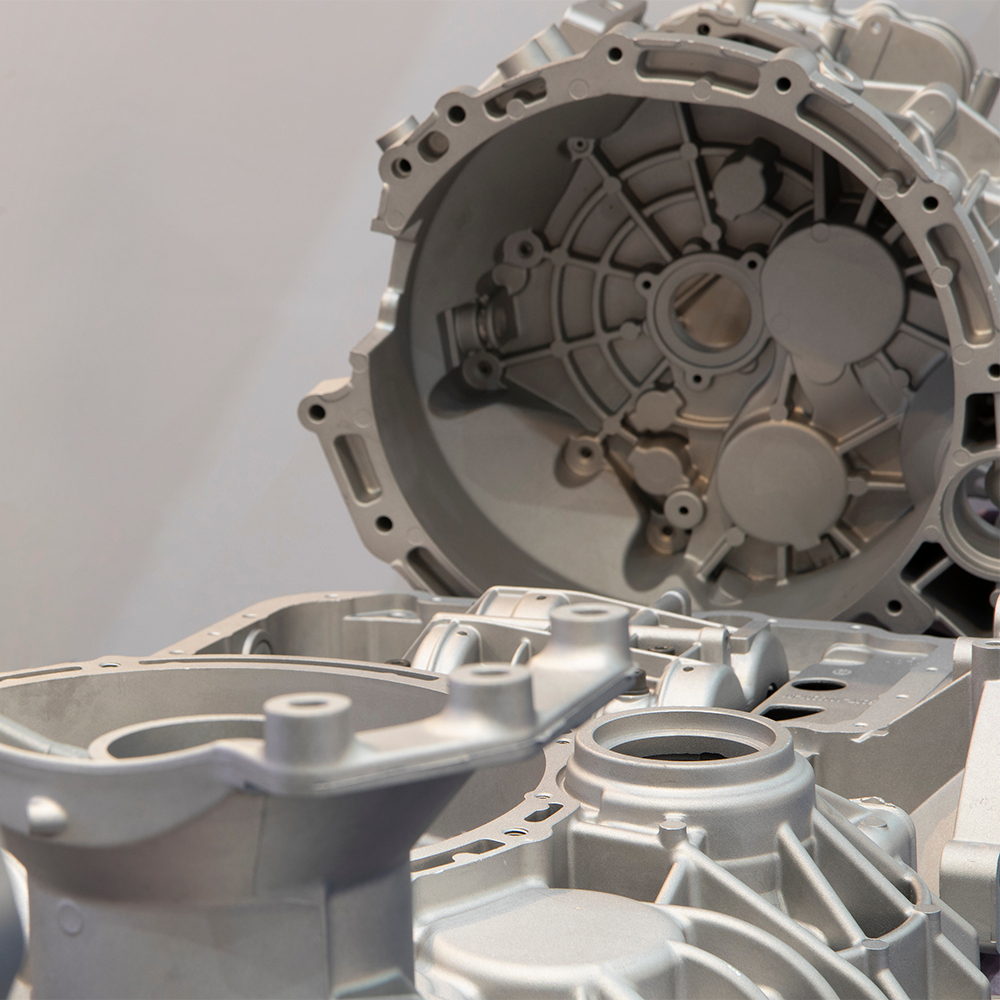

Thin dense chrome (TDC) was formulated to solve the need for a protective coating that wouldn’t alter dimensions of precision components. Traditional hard chrome plating was often too thick, which impacts part performance in applications requiring exact tolerances.

The innovation behind TDC includes:

- Enhanced wear and corrosion resistance without adding excessive thickness

- Improved performance in extreme environments, including high temperatures and harsh conditions

- Reduced friction for smoother operation and increased efficiency of moving parts

- Extended component lifespan, minimizing maintenance needs and downtime

Why Choose Electrolizing?

We are committed to providing the best in coating solutions that enhance the performance and durability of your components. Here’s why our partners choose us:

Rigorous Process Control

Our process fulfillment center follows strict guidelines established by The Armoloy Corporation, ensuring consistent, high-quality metal surface treatments.

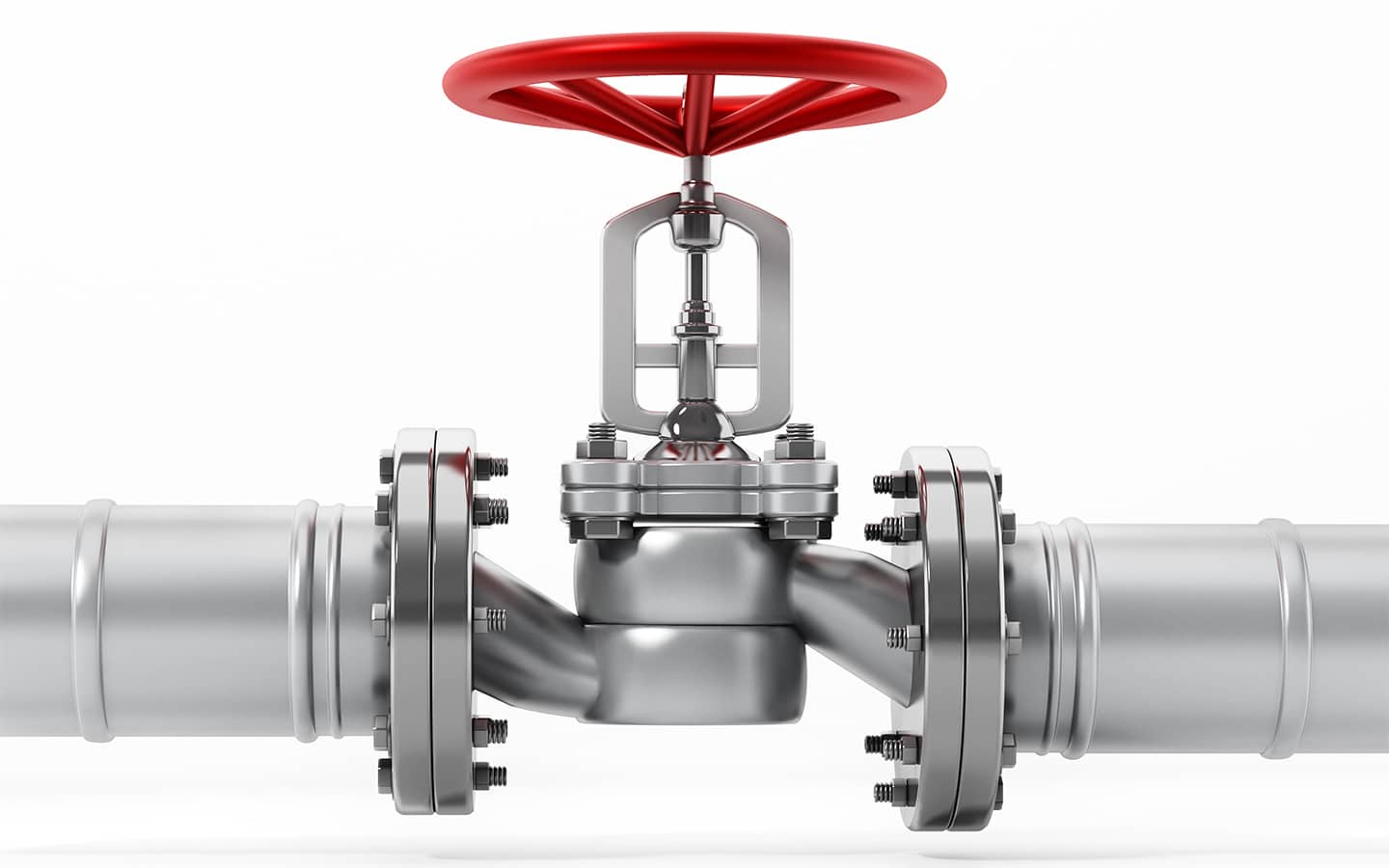

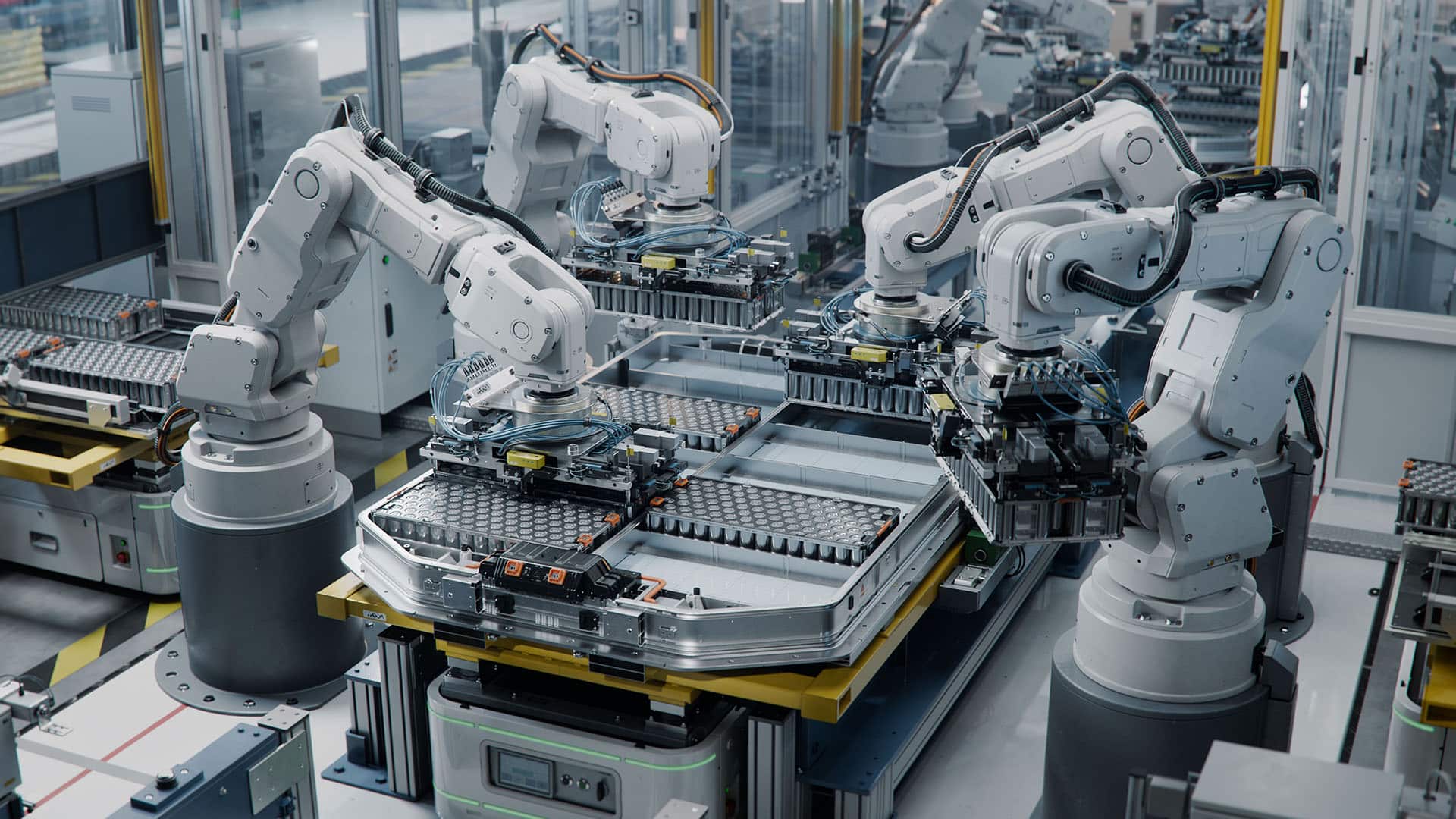

Broad Industry Applications

Electrolizing coatings are trusted in diverse industries, including aerospace, medical, and food processing. Their versatility makes them ideal for protecting components in the harshest environments.

Cost-Effective Solutions

Our metal surface treatments extend the lifespan of components, reducing maintenance needs and downtime. This leads to significant cost savings and improved operational efficiency.

Global Reach and Consistency

As part of the Armoloy network with 15 licensed processing facilities worldwide, we guarantee the same high-quality coating technology and reliable results, regardless of location.

Core Components of Process Development & Validation

Process Development

This involves designing and developing consistent, repeatable plating processes tailored to specific requirements. It includes the selection of materials, equipment, and the establishment of training programs for plating workflows and quality control measures.

Process Validation

Process validation provides documented evidence that a process will consistently produce a product that meets its predetermined specifications and quality attributes. It typically includes stages like process design, process qualification, and continued process verification.

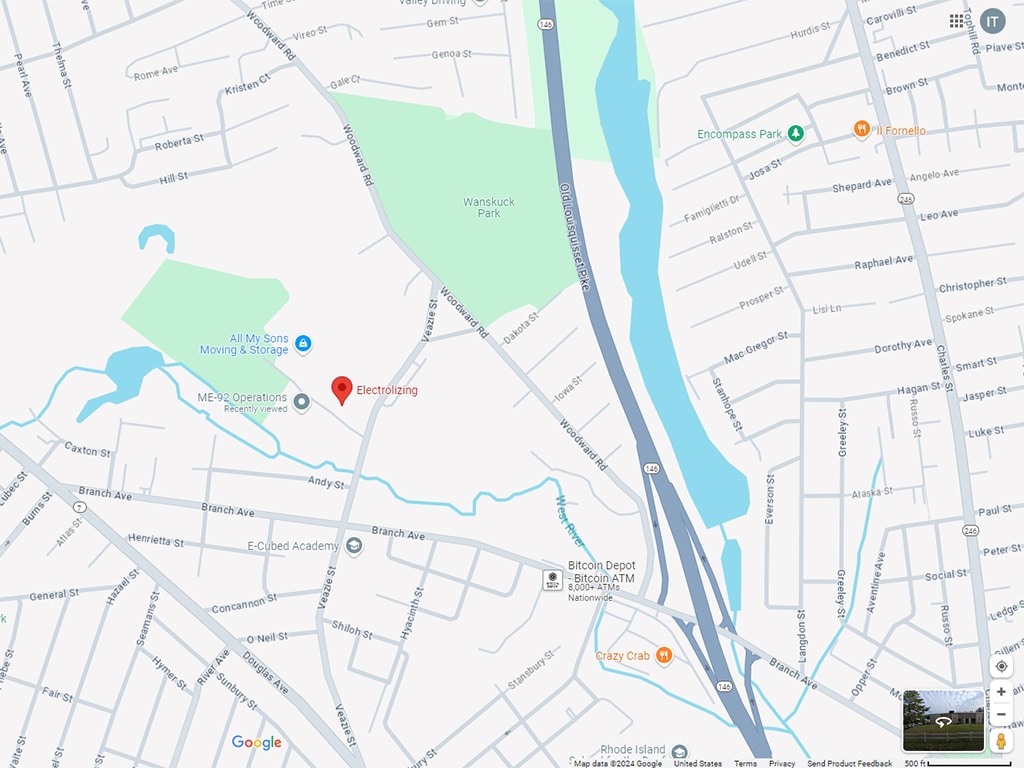

Process Development Centers

Armoloy’s development centers near Chicago, Illinois, and Providence, Rhode Island, are essential for fostering innovation and ensuring the repeatability of processes. These centers are essential for:

- Centralizing expertise and housing state-of-the-art laboratories

- Innovating and improving plating technologies and methodologies

- Mitigating risks early in the development cycle

- Enhancing customer collaboration to align development processes with customer needs and expectations

We certify to many plating and testing specifications—capable of meeting an expansive list of customer and industry needs. Below is a brief list of specifications available.

We offer certification for many plating and testing standards—capable of meeting your requirements. View our list below to see the certifications available.

Partner with Electrolizing

Eliminate metal failure from your operations. Get in touch with an Electrolizing metal coating specialist today and learn how we can help improve your industry with science-based solutions.