Molybdenum disulfide (MoS2) is best known as a high-performance solid lubricant. It excels in extreme environments where traditional lubricants fail, offering low friction and excellent load-carrying capabilities.

Common Applications of MoS2:

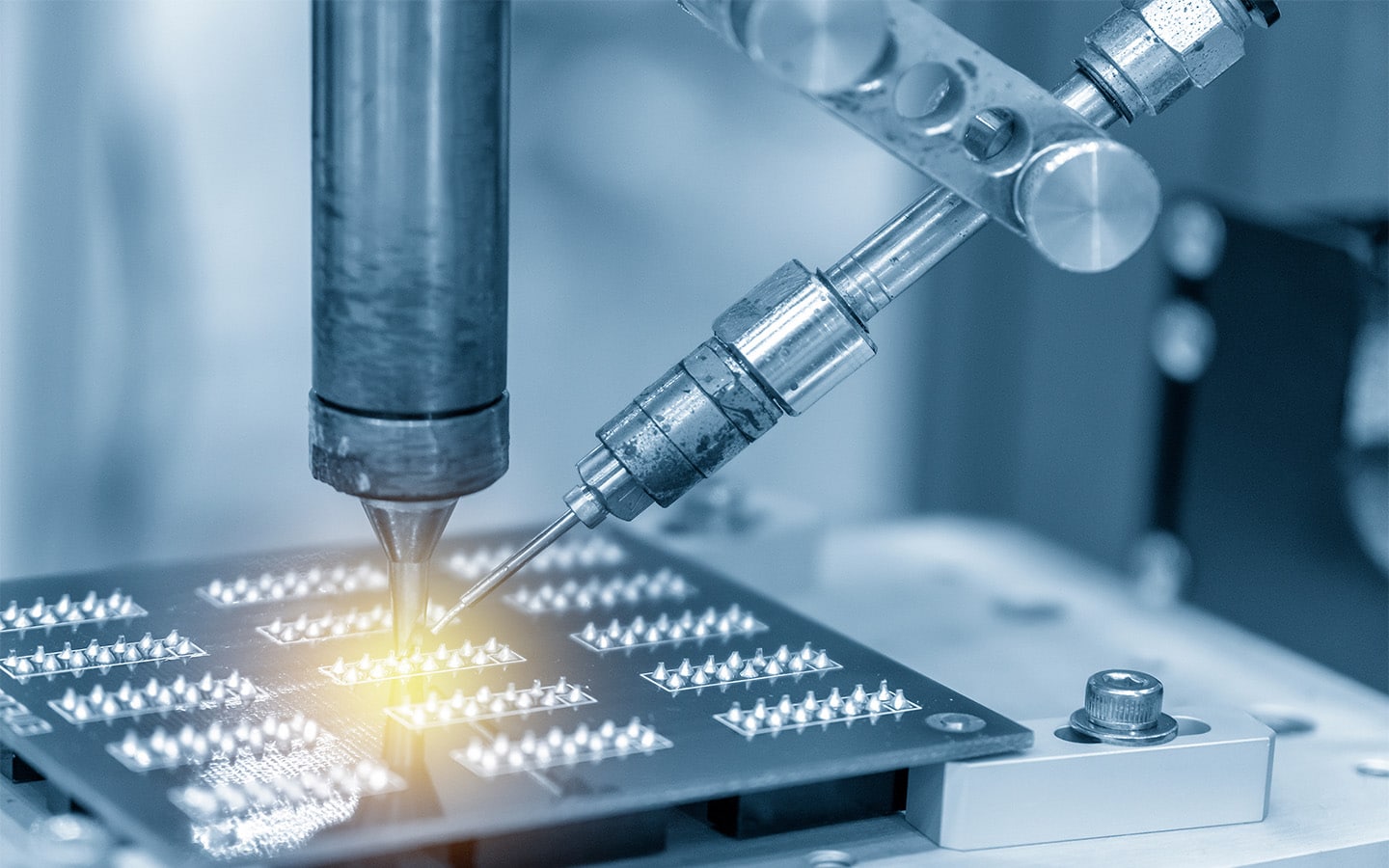

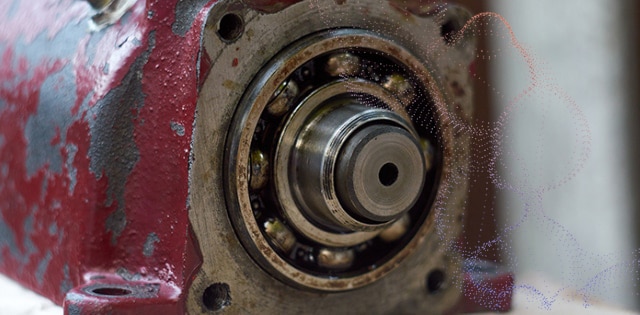

- Dry Film Lubricants: Used in aerospace, defense, and automotive sectors to reduce wear and prevent galling in moving metal components.

- High-Temperature Greases: Added to lubricating oils and greases to enhance performance under thermal and mechanical stress.

- Anti-Friction Coatings: Applied to parts like gears, cams, and threaded fasteners to minimize friction in extreme-pressure conditions.

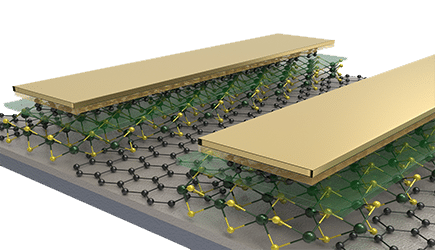

- Electronics & Semiconductors: Valued for its unique electronic and optoelectronic properties in nanoscale applications.

- Catalysis: Acts as a catalyst in hydrodesulfurization and other chemical reactions.

MoS2 is ideal for demanding applications where reliable, long-term lubrication is essential — especially in environments where oil or grease can’t be used.