Armoloy Specifications

What is ASTM D4060?

ASTM D4060 is a standardized test method developed by ASTM International to evaluate the abrasion resistance of coatings using a Taber Abraser. This test measures a coating’s ability to withstand abrasive wear by tracking material loss after controlled, repeated abrasion. Commonly cited in product specifications and industry accreditations like ISO 9001:2015, it supports quality control for abrasion-critical applications.

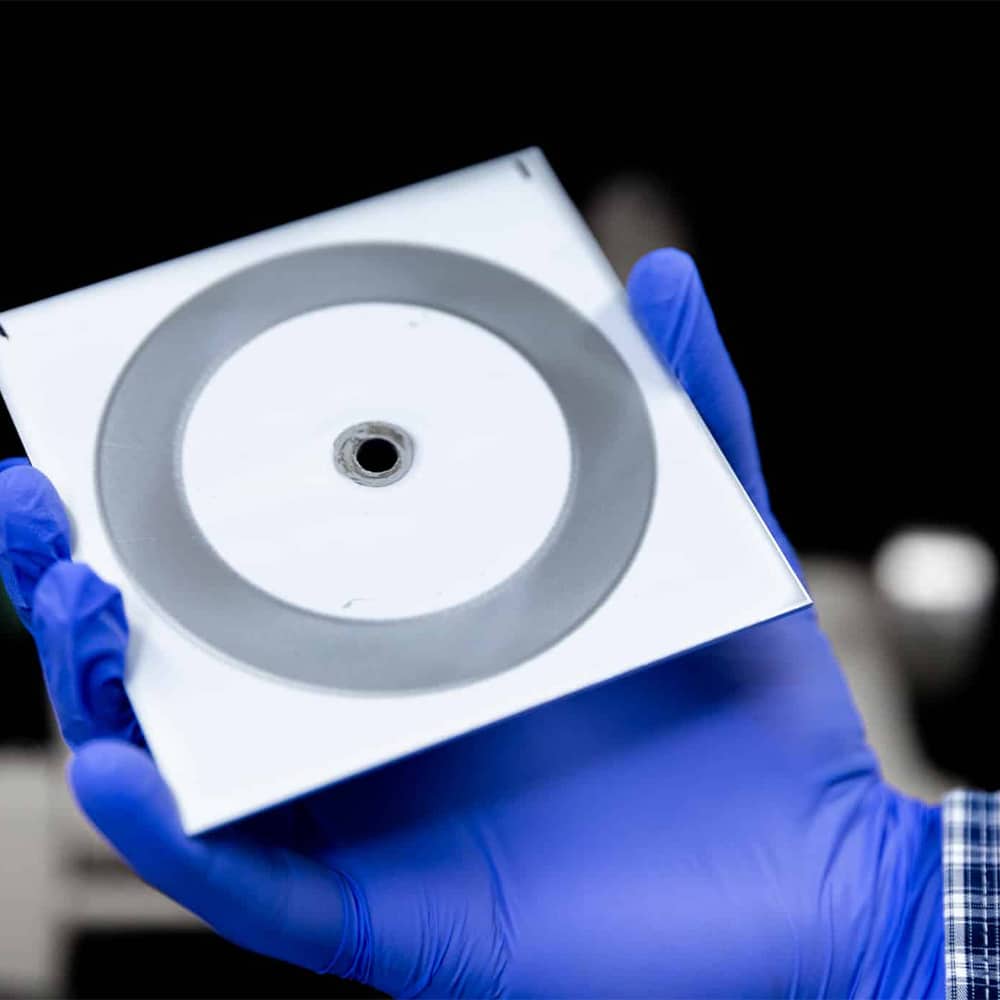

The test involves mounting a coated specimen on a rotating turntable and abrading it with two weighted wheels under specified pressure. After a set number of cycles, the specimen is reweighed to determine how much material was lost. Results are typically expressed as weight loss in milligrams or as a calculated wear index.

Initially intended for organic coatings such as paints and polymers, ASTM D4060 is also used to evaluate harder finishes such as electroplating, anodizing, and thermal sprays when applied to flat, rigid substrates. Variables like wheel type, test duration, and load can be adjusted to simulate different wear conditions.

Manufacturers, finishers, and quality teams rely on this method to understand how coatings perform under friction, handling, or repeated contact. ASTM D4060 offers a repeatable, quantifiable way to compare coating durability across a range of materials and surface treatments.

The Role of ASTM D4060 in Abrasion Resistance Testing

ASTM D4060 plays a pivotal role in helping manufacturers evaluate the durability of coated surfaces. By offering a consistent testing protocol, it helps companies:

- Standardize Testing: Ensures consistent results across coatings, laboratories, and production batches.

- Select the Right Coating: Helps identify coatings that meet specific performance criteria under friction, handling, or mechanical wear.

- Improve Quality Control: Allows monitoring of coating consistency and early detection of performance issues.

- Validate Durability Claims: Backs up abrasion-resistance claims with quantifiable data suitable for technical documentation and customer assurance.

Whether for proving product reliability or optimizing surface treatments, ASTM D4060 provides a measurable edge in coating performance evaluation.

ASTM D4060 Testing Methodology & Results

The ASTM D4060 test quantifies how much material a coating loses under controlled abrasion. The process uses a Taber Abraser to simulate wear through the following steps:

- Prepare the Sample: Coatings are applied to flat, rigid substrates and conditioned as per standard requirements.

- Set the Machine: The sample is mounted on a rotating turntable, with two abrasive wheels placed under a prescribed load.

- Abrasion Testing: The specimen rotates for a specified number of cycles, simulating repeated mechanical contact.

- Measure Results: After testing, the sample is reweighed. Material loss is recorded in milligrams or as a wear index.

These results offer a standardized benchmark to evaluate abrasion resistance across different coatings and surface treatments.

Industries That Use ASTM D4060

ASTM D4060 is applicable across industries where coatings are exposed to friction, surface contact, and wear. Common sectors include:

- Bearings: Assesses coating longevity under rotational stress and continuous contact.

- Food Processing Equipment: Tests wear resistance on surfaces exposed to harsh cleaning, abrasive foods, and continuous use.

- Pumps: Evaluates coatings on impellers, housings, and internal components subjected to abrasive fluids.

- Injection Molding: Verifies that coatings endure repeated high-friction cycles during part ejection and molding operations.

For manufacturers in these fields, ASTM D4060 provides a trusted method for extending the life of critical components and validating product quality.

Benefits of Working with an ASTM D4060 Provider

Reliable durability testing

Standardized procedures ensure accurate, repeatable results

Quality assurance

Testing uses calibrated equipment and conforms to ASTM standards

Longer component life

Helps optimize coatings to reduce wear, failure, and replacement frequency

Standards compliance

Supports certifications and product qualification in regulated industries

Consistent results

Uniform testing protocols deliver predictable outcomes across batches

Clear documentation

Provides traceable test reports for audits, QA, and technical data sheets

Proven expertise

Professional providers offer confidence in test validity and data accuracy

Custom test scenarios

Test conditions can be tailored to replicate real-world applications

Specifications at Armoloy

Armoloy offers plating solutions that meet ASTM D4060 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to ASTM D4060, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of ASTM D4060 within its own processes and does not constitute official or authorized guidance from ASTM International.

ASTM D4060 is a proprietary standard developed and owned by ASTM International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. References to ASTM D4060 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized abrasion resistance testing standards.

This content is not intended to substitute for the official specification, which should be obtained directly from ASTM International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.