Armoloy Specifications

What is ASTM B117?

ASTM B117 is the industry standard for evaluating corrosion resistance using a controlled salt spray (fog) test. It is widely used in quality control and process validation, and often referenced in specifications and programs such as ASTM B650 and Nadcap Certification.

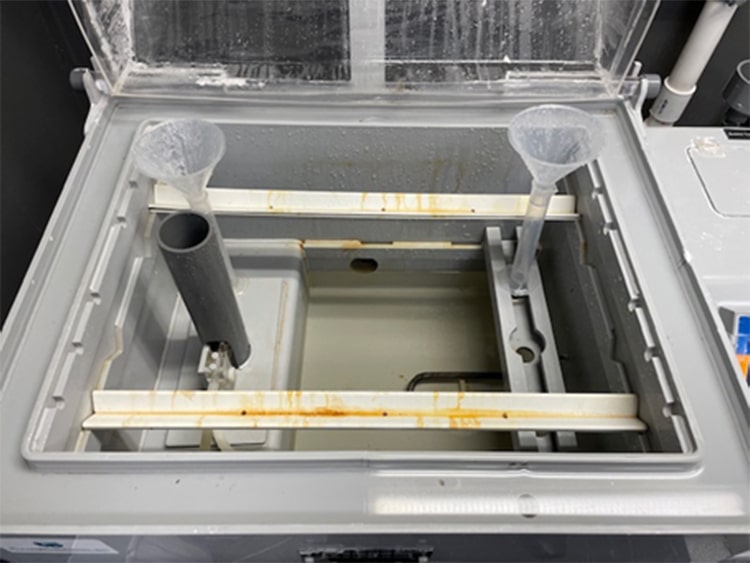

Developed by ASTM International, it simulates harsh environments by exposing samples to a 4-6% sodium chloride (NaCl) mist in a chamber maintained at 35°C (95°F). Testing durations range from 24 hours to over 1,000 hours, depending on material requirements.

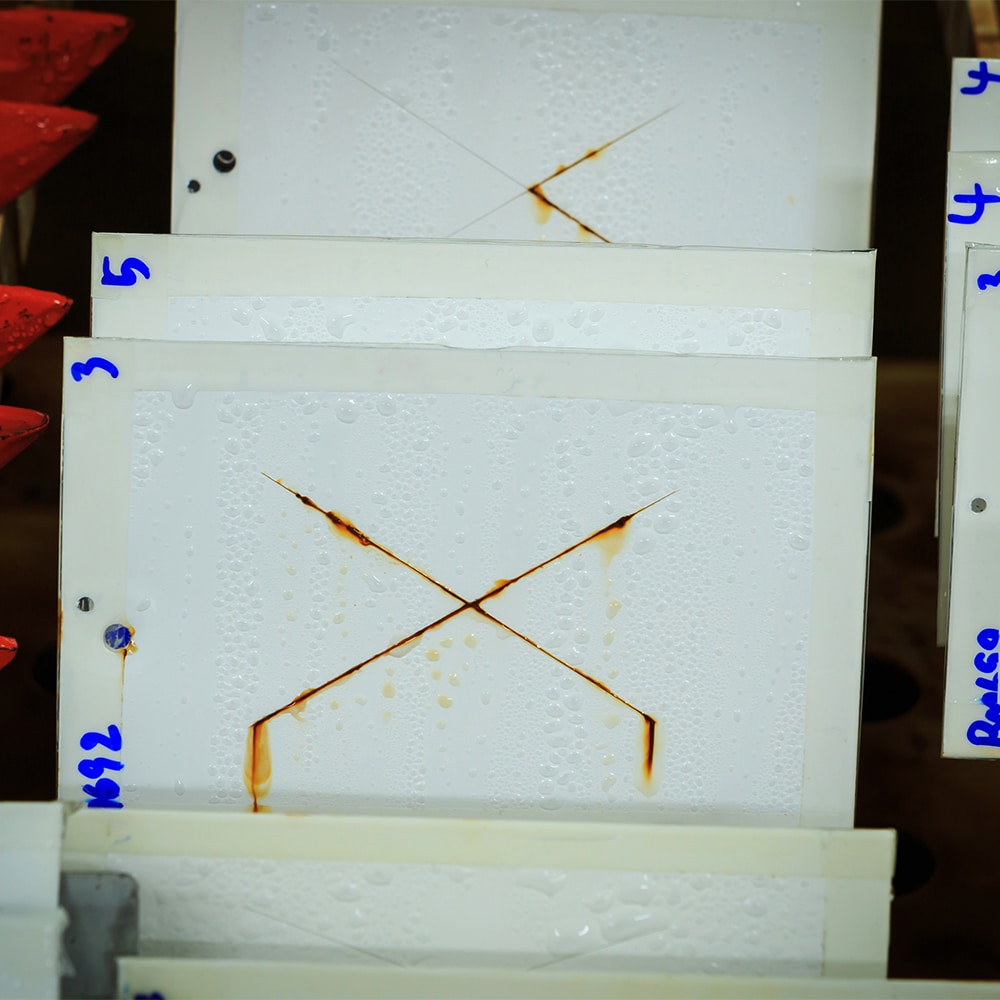

After exposure, samples are evaluated for rust, pitting, and surface degradation, providing valuable insights and comparisons of material performance. While the test doesn’t directly predict real-world performance, it is widely used in the aerospace, automotive, and defense industries to benchmark corrosion protection.

This test applies to metals like steel, aluminum, and stainless steel, as well as coatings such as chrome, zinc, and nickel. Its versatility and ease of use make ASTM B117 a critical tool for improving material longevity and performance.

The Role of ASTM B117 in Corrosion Resistance Testing

ASTM B117 is the leading industry benchmark for evaluating corrosion resistance in the U.S., providing a controlled method to simulate salt-laden environments. Its key contributions include:

- Standardized Testing: Provides consistent, repeatable conditions for comparing material and coating performance.

- Industry Benchmark: Used globally to streamline compliance, product validation, and cross-industry collaboration.

- Quality Assurance: Helps manufacturers confirm that materials and coatings meet durability standards before real-world use.

- Advancing Materials Science: Supports the development of advanced protective coatings and corrosion-resistant materials.

As a cornerstone of corrosion testing, ASTM B117 ensures manufacturers can engineer products that withstand harsh environments and maintain long-term performance.

ASTM B117 Testing Methodology & Results

ASTM B117 follows a standardized procedure to assess corrosion resistance in a controlled salt spray environment. Key steps include:

- Sample Preparation: Materials are cleaned and prepped to match real-world applications.

- Testing Chamber Setup: Samples are placed in a chamber that sprays a fine mist of 4-6% sodium chloride (NaCl) solution at 35°C (95°F), with a controlled pH between 6.5 and 7.2.

- Exposure Duration: Test lengths vary based on material requirements, often lasting 24, 48, or over 1,000 hours.

- Corrosion Inspection: Samples are examined for rust, pitting, and surface damage using visual and analytical methods.

- Performance Evaluation: Results are measured by time to first corrosion or surface deterioration percentage, providing a comparative corrosion resistance metric.

While ASTM B117 cannot predict real-world performance, it remains a vital tool for comparing materials and coatings.

Industries that Use ASTM B117

ASTM B117 is a cornerstone for industries that demand corrosion resistance:

- Aerospace: Protects fasteners, landing gear, and structures from harsh conditions.

- Automotive: Ensures trim, wheels, and engine parts withstand road salt and moisture.

- Medical Devices: Prevents corrosion in surgical tools and implants.

- Oil and Gas: Shields pipelines, valves, and drilling equipment from corrosive environments.

- Packaging: Preserves metal coatings on moisture-exposed materials.

- Semiconductors: Extends the lifespan of components in industrial and outdoor settings.

By standardizing corrosion testing, ASTM B117 helps industries build durable, high-performance materials.

Benefits of Working with an ASTM B117 Provider

Proven quality

Comprehensive testing ensures materials meet corrosion resistance standards

Industry compliance

Providers ensure components meet or exceed regulatory requirements for automotive, aerospace, and industrial applications

Technical expertise

Experienced teams offer guidance on material selection and optimized protective coatings

Risk mitigation

Prevents premature failures, minimizing downtime and disruptions

Efficient resource allocation

Outsourcing corrosion testing to an ASTM B117-adherent laboratory with ASTM B117 capabilities frees up internal resources for core operations

Enhanced product development

Providers use test results to refine coatings and materials, improving product performance

Comprehensive reporting

Documentation supports traceability and informed decision-making

Global compatibility

Testing aligns with international standards like ISO 9227, supporting seamless global integration

Specifications at Armoloy

Armoloy offers plating solutions that meet ASTM B117 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to ASTM B117, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of ASTM B117 within its own processes and does not constitute official or authorized guidance from ASTM International.

ASTM B117 is a proprietary standard developed and owned by ASTM International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. References to ASTM B117 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized corrosion testing standards.

This content is not intended to substitute for the official specification, which should be obtained directly from ASTM International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.