Armoloy Specifications

What is AMS 2404?

Developed by the SAE Aerospace Material Specifications (AMS) Committee, AMS 2404 ensures exceptional wear resistance, corrosion protection, and solderability, even in extreme conditions up to 1000°F (538°C).

AMS 2404 sets a high standard for consistent, high-quality electroless nickel plating. It provides a trusted framework for quality control, compliance, and reliable performance across industries.

The Role of AMS 2404 in Electroless Nickel Plating

AMS 2404 standardizes electroless nickel plating for industries that require durable, precision-coated components across diverse applications. Its role includes:

- Consistency Across Batches: Establishes guidelines for uniform plating processes, delivering repeatable, high-quality results across production runs.

- Corrosion and Wear Resistance: Specifies parameters for creating durable coatings that protect against environmental degradation, friction, and abrasion.

- Precision and Uniformity: Enables even coverage on intricate and irregular surfaces, ensuring predictable functionality.

- Material Versatility: Supports plating on steel, aluminum, copper alloys, and more, expanding design possibilities.

- Stable, High-Performance Components: Reduces plating inconsistencies and ensures that plated components meet operational requirements.

AMS 2404 is crucial in advancing plating technology, supporting industries that require precision-engineered components built for endurance and peak efficiency.

AMS 2404 Testing Methodology & Results

AMS 2404 mandates various tests to comply with its electroless nickel plating specifications:

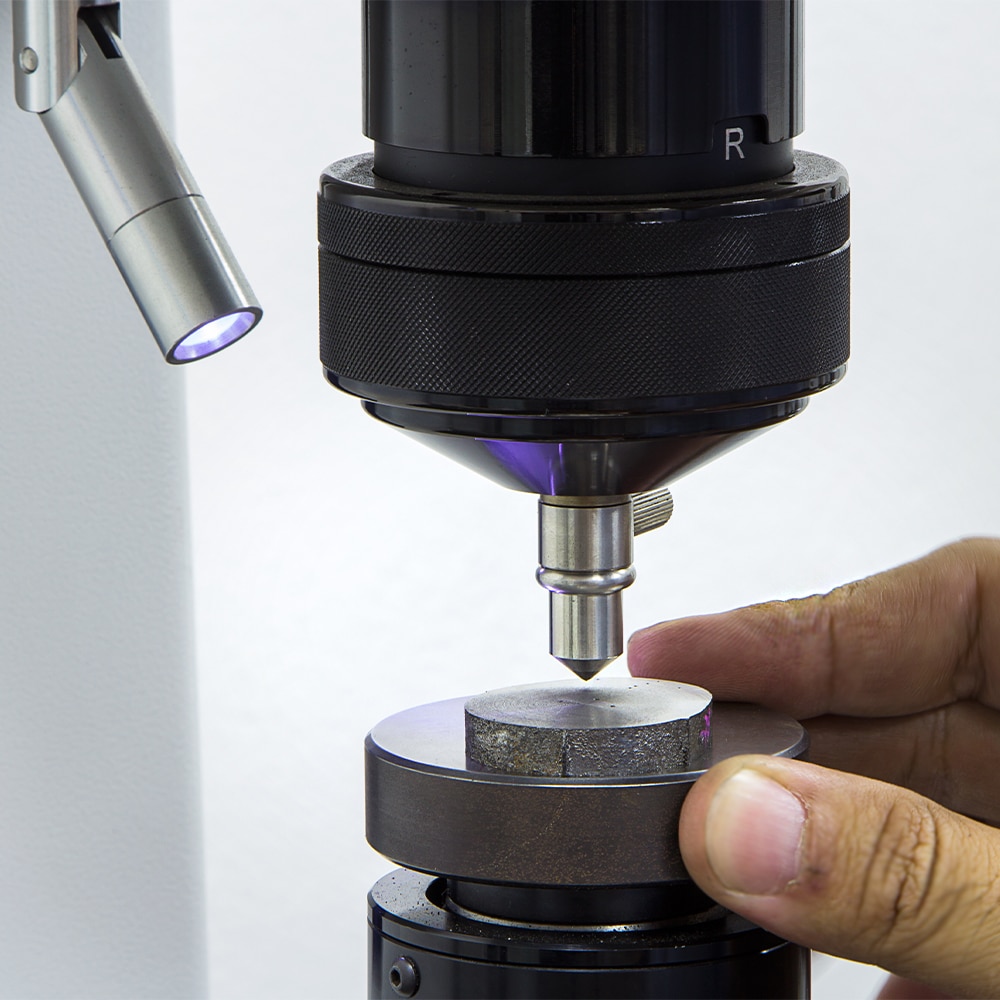

- Thickness Measured: Verifies coating thickness using X-ray fluorescence (XRF), beta backscatter, or microscopical examination.

- Adhesion Testing: Evaluates the bond strength of the nickel-phosphorus coating to the substrate through thermal cycling or bend tests .

- Corrosion Resistance Testing: Assesses plating resilience using salt spray testing to confirm protection in harsh environments.

- Microhardness Testing (Knoop): Measures hardness to confirm performance, primarily for Class 2 coatings with specific hardness requirements.

- Chemical Composition Analysis: Verifies the amount of phosphorus in the nickel coating to match its specific class and performance needs.

- Thermal Treatments by Class: Tailors heat treatments to enhance coating properties based on specific class requirements:

- Class 1: No post-plating thermal treatment, except hydrogen embrittlement relief when necessary, ensuring basic functionality without altering the coating.

- Class 2: Heat-treated at 450°F (232°C) or higher to improve hardness and wear resistance.

- Class 3: Treated at 375°F (191°C) to enhance adhesion on non-heat-treatable substrates, such as specific aluminum or beryllium alloys.

- Class 4: Special thermal treatment for heat-treatable aluminum alloys to optimize coating adhesion.

- Visual and Surface Inspection: Ensures uniformity, smoothness, and defect-free finishes.

By adhering to these methodologies, the standard ensures electroless nickel coatings meet the demands of critical applications, offering reliable performance in challenging environments.

Industries that Use AMS 2404

AMS 2404 plays a key role in industries that depend on precision coatings for functional performance and long-term stability:

- Aerospace: Protects turbine blades, engine parts, and landing gear from wear and environmental exposure.

- Automotive: Enhances fuel injectors, pistons, and transmission components for efficient operation and extended lifespan.

- Oil and Gas: Strengthens drilling and refining equipment against high temperatures and chemical exposure.

- Medical Devices: Supports biocompatibility and material integrity in surgical tools, implants, and diagnostic instruments.

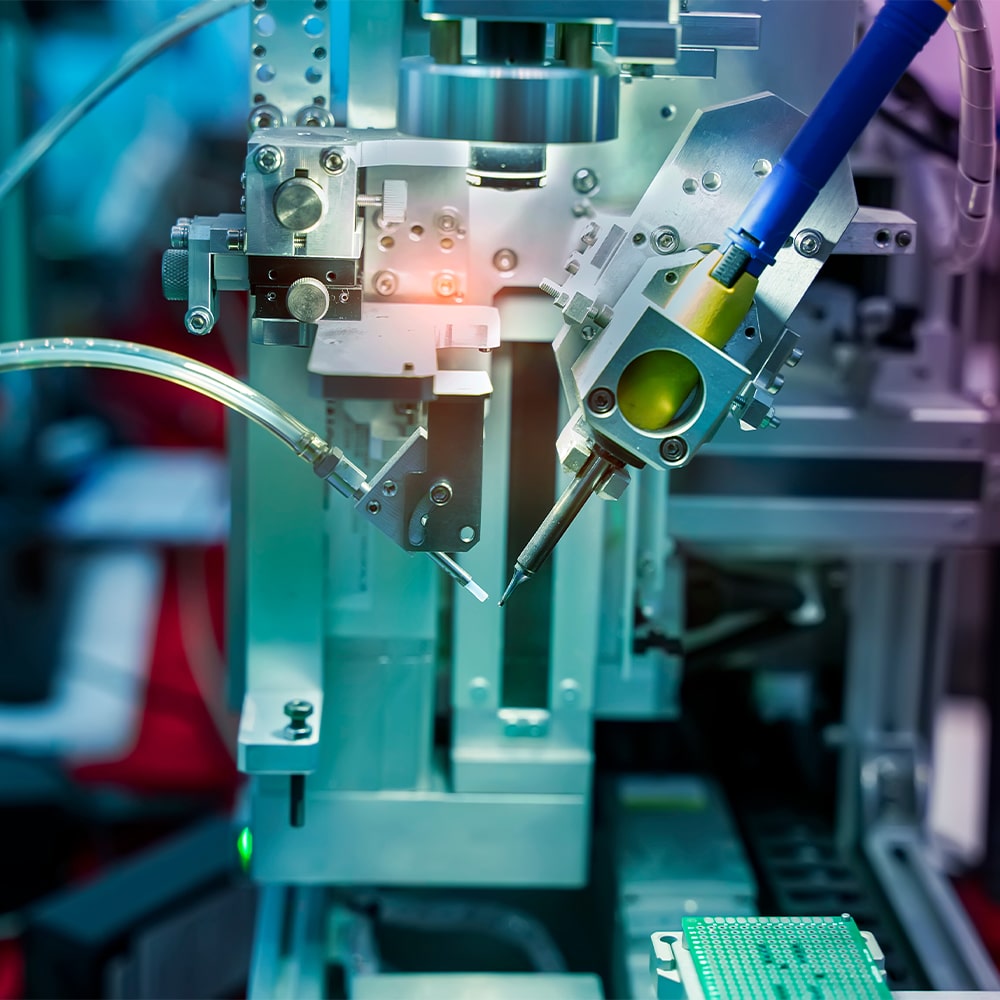

- Semiconductors: Improves solderability and performance in connectors, circuit boards, and microelectronic components.

AMS 2404 helps industries maintain precise coating quality, optimizing components for specialized applications in demanding environments.

Benefits of Working with an AMS 2404 Provider

Guaranteed compliance

AMS 2404-compliant providers meet stringent plating standards, ensuring components are built to exact specifications

Advanced process control

Providers implement refined procedures to ensure uniform and defect-free nickel coatings for all parts

Electroless nickel expertise

Providers bring expertise in electroless nickel plating, offering tailored solutions for complex requirements

Reliable performance

Precision application minimizes variability, ensuring consistent performance in critical applications

Comprehensive testing

Providers conduct rigorous quality checks, such as adhesion and thickness tests, to meet high-performance demands

Adaptable solutions

Providers tailor coatings to diverse needs, from wear-resistant machinery to precision medical devices

Audit support

Providers maintain comprehensive records to support compliance, traceability, and customer audits

Global expertise

Adherence aligns with international standards, supporting seamless integration into global supply chains

Specifications at Armoloy

Armoloy offers plating solutions that meet AMS 2404 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to AMS 2404, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of AMS 2404 within its own processes and does not constitute official or authorized guidance from SAE International.

AMS 2404 is a proprietary standard developed and owned by SAE International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. References to AMS 2404 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized plating standards.

This content is not intended to substitute for the official specification, which should be obtained directly from SAE International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.