Armoloy’s thin dense chrome coatings create a low-friction, smooth surface that resists the buildup of lint, dyes, and fiber particles. This keeps textile equipment running cleaner and more efficiently, particularly in environments where natural or synthetic fibers create residue that can otherwise lead to wear or product contamination.

the fabric of protection

The Purpose of Coatings for Textile Machinery

Benefits of Coating Services for Textile Machinery from Armoloy

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Start-to-Finish Surface Solutions

- Armoloy provides full-scope surface treatment solutions designed to enhance equipment performance and longevity. From initial consultation through application and final inspection, we guide every project with technical expertise and attention to detail.

Reliable Processes, Repeatable Results

- Our innovation center develops and validates coating methods built for consistent, long-term performance. These processes are applied across our global fulfillment network—ensuring every component receives the same high-quality finish, wherever it’s coated.

Global Reach. Local Dependability

- With fulfillment centers strategically located worldwide, Armoloy delivers coatings on time and to spec. Our international footprint ensures you get the protection and performance you need—no matter where your textile operations take place.

Process Accreditations at Armoloy

Armoloy coatings have passed the rigorous quality requirements for the following standards:

- AS9100D

- ISO 9001:2015

- ISO 10993

- RoHS Compliance

- NADCAP

- ISO 19011

- ISO 14001:2015

- WEEE Compliance

- REACH Compliance

Coating Specifications at Armoloy

Armoloy ensures compliance with industry standards, such as ASTM D737-18, and specifications to meet the rigorous demands of textile machinery coatings.

Applications of Coatings for Textile Machinery

Armoloy coatings enhance the functionality of various textile machinery components and applications, including:

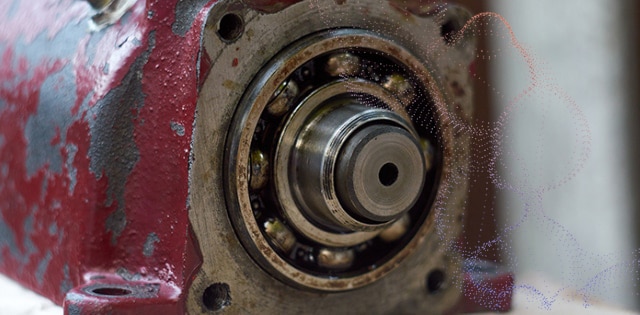

- Bearing surfaces

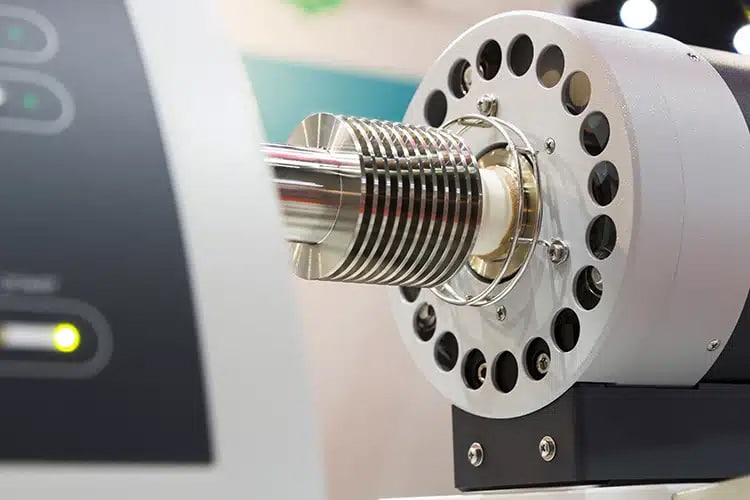

- Rollers

- Cutters

- Cylinders

- Gears & sprockets

- Heat sealing equipment

- Hydraulic valves, pistons & housings

- Linear motion guides

- Plastic extrusion molding

- Stamps

Frequently Asked Questions

Armoloy coatings are ideal for rollers, guides, cams, shafts, spindles, and feed mechanisms in textile machines. These parts are subject to constant friction, fiber abrasion, and chemical exposure. Our coatings extend their life by reducing wear and galling, helping maintain smoother fabric handling and minimizing machine downtime.

Dealing with abrasion or buildup? Let’s protect your equipment.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.