Absolutely. Armoloy coatings offer outstanding resistance to etchants, cleaning chemistries, plasma environments, and reactive gases used in deposition, etching, and cleaning processes. Their hard, dense surface protects stainless steel, aluminum, and other base materials from pitting, erosion, and surface breakdown—helping extend component life in high-throughput semiconductor tools.

advancing advanced materials

The Purpose of Semiconductor Coatings

Benefits of Semiconductor Plating Services from Armoloy

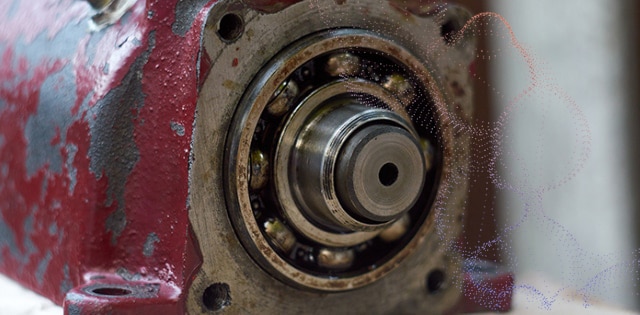

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

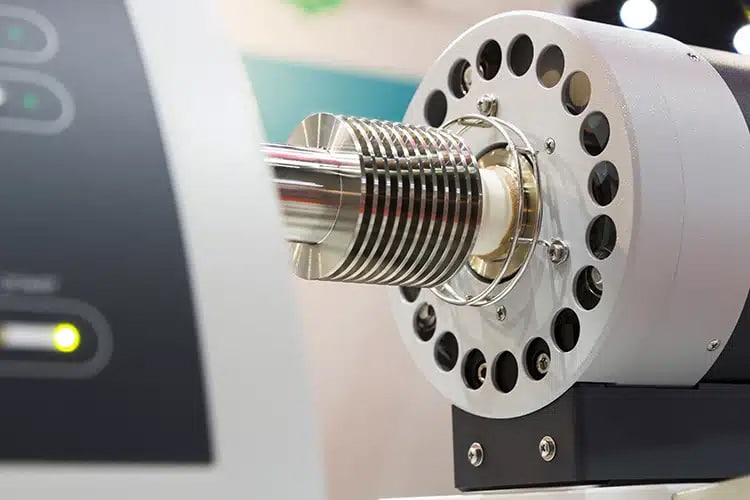

High-Precision Surface Solutions

- Armoloy provides full-service coating support for the semiconductor industry, where cleanliness, precision, and durability are critical. From initial consultation through application and inspection, our metallurgical team ensures every surface treatment meets strict process demands.

Repeatable Processes for Sensitive Environments

- Our innovation center develops and rigorously validates coating methods designed for stability, repeatability, and minimal particle generation. These standardized processes are deployed globally to ensure consistent performance across cleanroom-compatible components.

Global Coverage with Uniform Results

- With fulfillment centers across key regions, Armoloy delivers coatings on time and to exacting standards. Our worldwide network ensures that semiconductor manufacturers receive the same quality and precision, wherever their production takes place.

Process Accreditations at Armoloy

Armoloy coatings are fully compliant with most customer-specific standards throughout the chrome coatings industry.

- AS9100D

- ISO 9001:2015

- ISO 10993

- RoHS Compliance

- NADCAP

- ISO 19011

- ISO 14001:2015

- WEEE Compliance

- NAMSA

- REACH Compliance

Coating Specifications at Armoloy

Armoloy coatings are compliant with most customer-specific standards throughout the chrome coatings industry.

Frequently Asked Questions

Yes. Armoloy coatings are non-outgassing, non-flaking, and stable under vacuum, making them suitable for Class 1–1000 cleanrooms and UHV applications. Their smooth, micro-cracked or nodular surfaces resist particle generation and help prevent contamination—an essential factor in front-end semiconductor processing and lithography equipment.

Armoloy coatings enhance the performance of wafer handling tools, vacuum chamber parts, precision guides, and actuating systems by providing low-friction movement, corrosion resistance, and surface protection. This ensures consistent tool performance in high-vacuum, high-temperature, and chemically aggressive environments while maintaining cleanliness standards critical to wafer fabrication and inspection.

Fabricating with precision? Let’s protect your surfaces.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.