Armoloy coatings offer impressive resistance to hydrogen sulfide (H₂S), chlorides, brines, and other corrosive fluids encountered in upstream and midstream operations. They prevent pitting, crevice corrosion, and stress corrosion cracking — making them ideal for components exposed to sour service, offshore conditions, or high-pressure fluid transport.

proven in the toughest conditions

Oil and Gas Coatings for High-Stress Environments

In addition to protecting from corrosion and wear, the unique surface properties of Armoloy coatings can also improve media flow rates due to reduced friction. Our customers in the field have realized flow improvements of up to 10%.

Benefits of Oil and Gas Coatings from Armoloy

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Start-to-Finish Surface Solutions

- Armoloy delivers comprehensive surface treatment services designed to meet the extreme performance requirements of oil and gas applications. From design consultation to final quality checks, our metallurgical team ensures your components are protected and built to endure.

Process Development You Can Trust

- At our innovation center, we create and qualify coating methods engineered for repeatability and resilience. These validated processes are standardized across all Armoloy fulfillment locations—so your parts receive the same high-performance treatment, no matter where they’re coated.

Global Reach. Consistent Protection

- With fulfillment centers located across key regions, Armoloy optimizes delivery and ensures coating consistency from site to site. Our worldwide footprint allows us to support oil and gas operations wherever they operate, from upstream drilling to downstream processing.

Process Accreditations at Armoloy

Armoloy oil and gas coatings comply with ASTM B117, ASTM D4060-10, and ASTM F519 and meet rigorous industry standards for corrosion resistance and durability. Our specialized processing tanks adhere to stringent ASTM specifications, ensuring our coatings provide excellent protection for all ferrous and non-ferrous base materials used in oil and gas applications.

- AS9100D

- ISO 9001:2015

- ISO 14001:2015

- RoHS Compliance

- NADCAP

- WEEE Compliance

- REACH Compliance

Coating Specifications at Armoloy

Armoloy oil and gas coatings comply with ASTM B117, ASTM D4060-10, ASTM F519, and MIL-C-26074 and meet rigorous industry standards for corrosion resistance and durability. Our specialized processing tanks adhere to stringent ASTM specifications, ensuring our coatings provide optimal protection for all ferrous and non-ferrous base materials used in oil and gas applications.

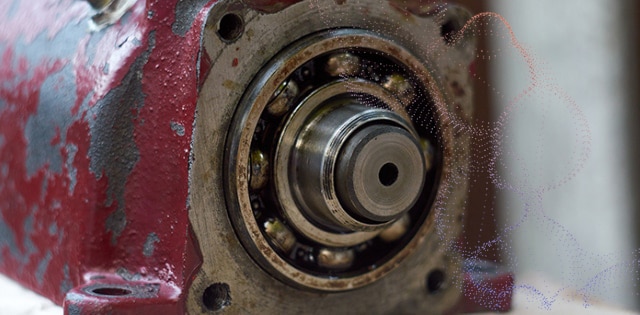

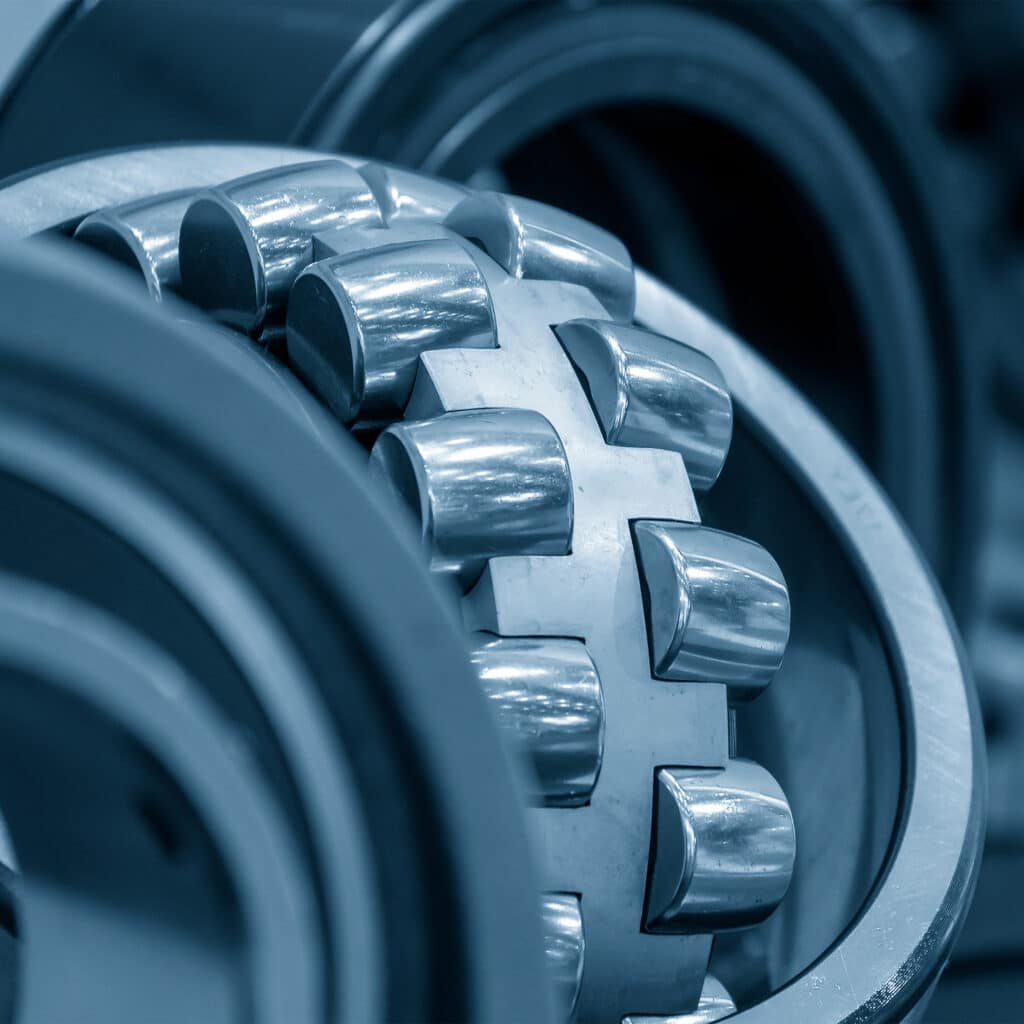

Oil and Gas Coating Applications

Armoloy coatings enhance the functionality of various oil and gas components and applications, including:

- Ball, swivel, universal & slip joints

- Bearing surfaces

- Drilling equipment

- Gears & sprockets

- Hydraulic valves, pistons & housings

- Impellers (oil, air, water)

- Pumps, shafts & liners

- Pistons, rings & rods

- Cylinders

Frequently Asked Questions

Armoloy coatings are ideal for downhole tools, valves, pump rods, actuator components, wear rings, and sealing surfaces that experience high loads, friction, and chemical exposure. Whether you’re operating in drilling, extraction, or refining environments, our coatings improve durability, reduce metal-on-metal contact, and extend part life under extreme pressure and temperature.

Challenging conditions? Let’s protect your equipment.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.