Our coatings are compatible with a wide range of materials used in the nuclear industry, including stainless steels, Inconel, Hastelloy, titanium, and tool steels. Whether you’re dealing with legacy reactor systems or next-gen SMR (Small Modular Reactor) components, Armoloy coatings provide consistent surface performance without compromising material integrity.

power up your protection

The Purpose of Nuclear Coatings

By shielding critical parts from radiation-induced degradation and chemical wear, nuclear coatings extend the lifespan of reactor components and reduce the risk of failures, thereby ensuring continuous and safe operation.

These coatings not only enhance the reliability of nuclear facilities but also play a key role in protecting the environment and public health by preventing the release of hazardous materials.

Benefits of Nuclear Plating Services from Armoloy

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Complete Surface Coating Oversight

- At Armoloy, we provide end-to-end surface treatment solutions backed by a fully equipped metallurgical lab and deep technical expertise. From the initial project review through coating application and final inspection, we ensure your components meet the rigorous standards required in nuclear applications.

Engineered Processes You Can Rely On

- Our innovation center is dedicated to designing and qualifying coating procedures that deliver predictable, repeatable outcomes. Once validated, these methods are implemented across our fulfillment locations to ensure uniform coating performance—regardless of where your parts are processed.

Global Capacity with Local Precision

- With strategically placed fulfillment centers worldwide, Armoloy delivers dependable service and consistent results. Our global reach allows us to meet tight timelines while maintaining the same stringent quality benchmarks across every region.

Process Accreditations at Armoloy

Armoloy nuclear coatings have undergone and passed rigorous testing to qualify for the following accreditations:

- AS9100D

- ISO 9001:2015

- ISO 14001:2015

- RoHS Compliance

- NADCAP

- WEEE Compliance

- REACH Compliance

- NAMSA

- ISO 19011

- ISO 10993

Coating Specifications at Armoloy

Armoloy nuclear coatings are fully compliant with ASTM D5144, NRC regulations, NQA-1, and most customer-specific standards throughout the nuclear coatings industry. We operate processing tanks dedicated to ASTM D5144 requirements, and our coatings can be applied to nearly all ferrous and non-ferrous base materials.

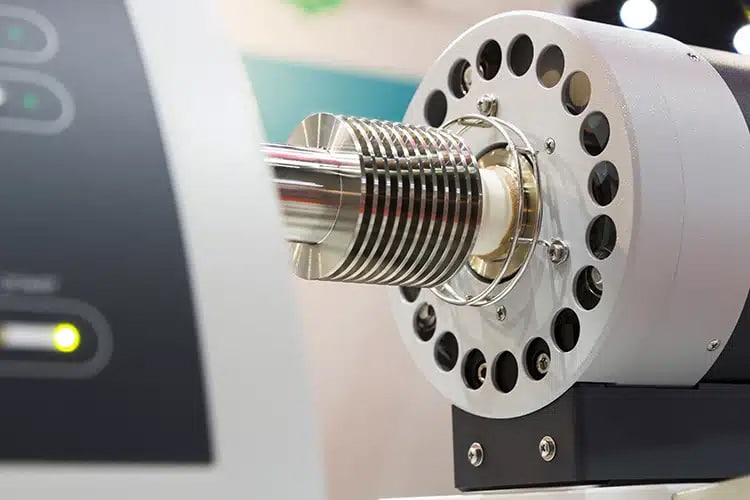

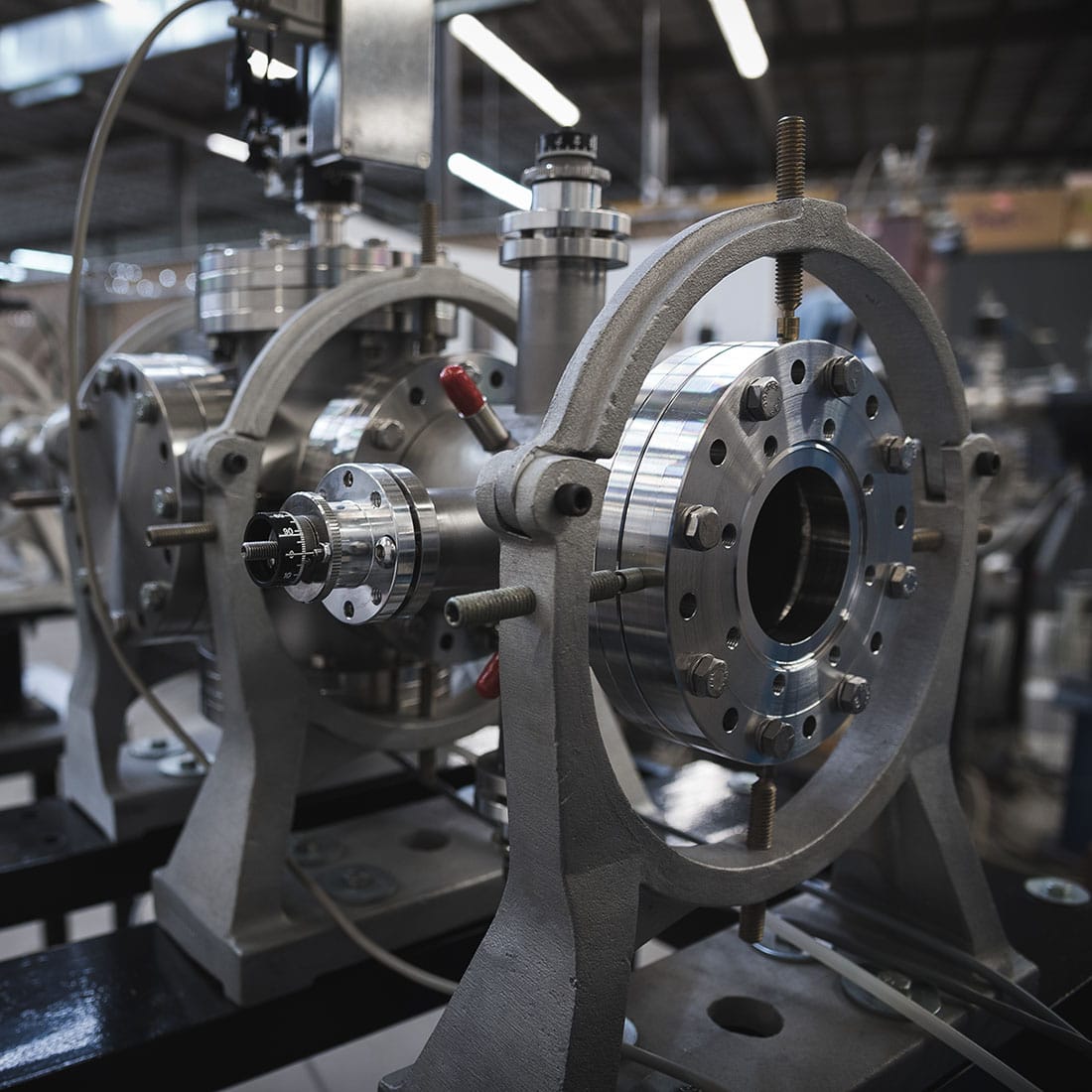

Nuclear Coatings Applications

Armoloy coatings enhance the functionality of various nuclear components and applications, including:

- Ball, swivel, universal & slip joints

- Bearing Surfaces

- Bushings

- Cylinders

- Drilling equipment

- Electronic components

- Gears & sprockets

- Hydraulic valves, pistons & housings

- Impellers (oil, air, water)

- Linear Motions Guides

- Power Transmission Systems

- Pump shafts & liners

- Robotic Joints

- Speciality Fasteners

Frequently Asked Questions

Armoloy’s coatings are engineered to remain stable in radiation-rich environments and under elevated temperatures, offering long-term protection against oxidation, wear, and corrosion. Their microcrystalline or nodular structure resists flaking and maintains adhesion even in aggressive coolant systems or vacuum chambers. These properties make them ideal for valve seats, pump shafts, control rods, and other mission-critical components.

Yes. Armoloy coatings have been applied to components used in commercial nuclear power plants, research reactors, and radioactive material handling systems. Our coatings meet strict requirements for dimensional consistency, corrosion resistance, and radiation stability, and can be processed under documentation-controlled environments when needed. Certifications and traceability can be provided to support nuclear QA programs.

Operating in extremes? Let’s talk nuclear-grade coatings

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.