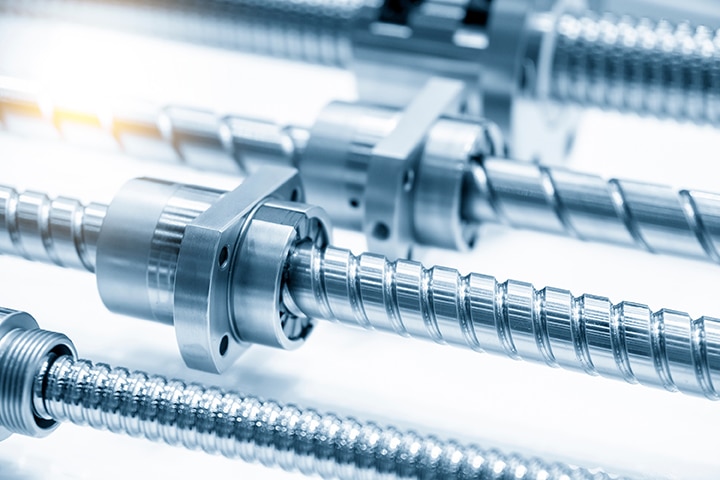

Not significantly. Armoloy Thin Dense Chrome (TDC) is engineered for precision applications and is applied in ultra-thin layers — generally between 0.0001″ and 0.0005″ per side. This minimal thickness allows components to retain critical dimensional tolerances, making TDC highly compatible with linear motion systems including bearings, guideways, and ball screws where clearance, alignment, and consistent movement are essential.

Thanks to its uniform deposition, TDC can usually be integrated into existing part geometries without requiring dimensional changes or adjustments to mating parts. This makes it a smart solution for high-precision systems in automation, robotics, and other motion-critical environments that demand both accuracy and durability.