Use a flanged bushing when you need radial + moderate axial in a compact part. For high axial or serviceable stacks, a separate thrust washer is easier to replace and size.

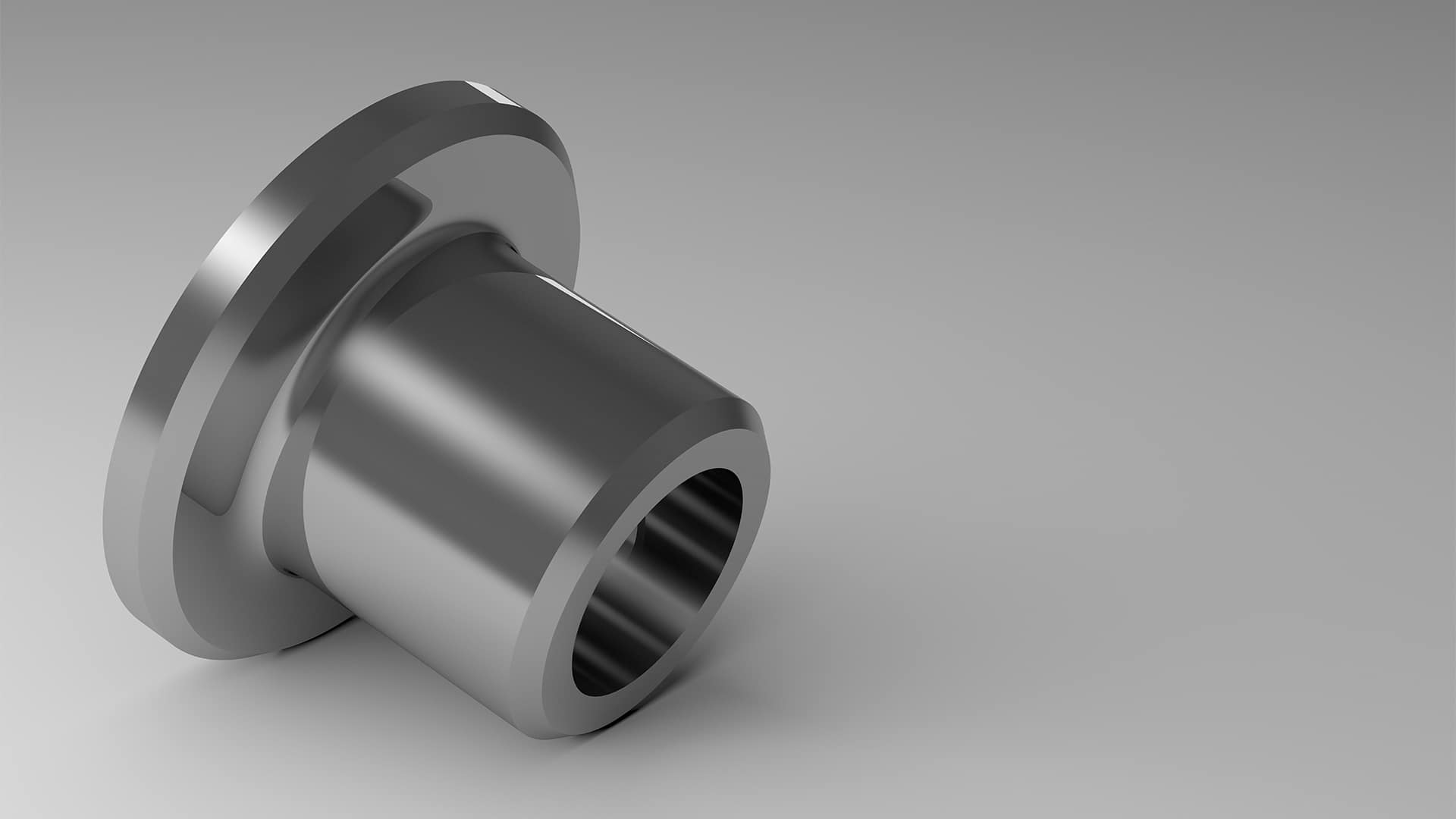

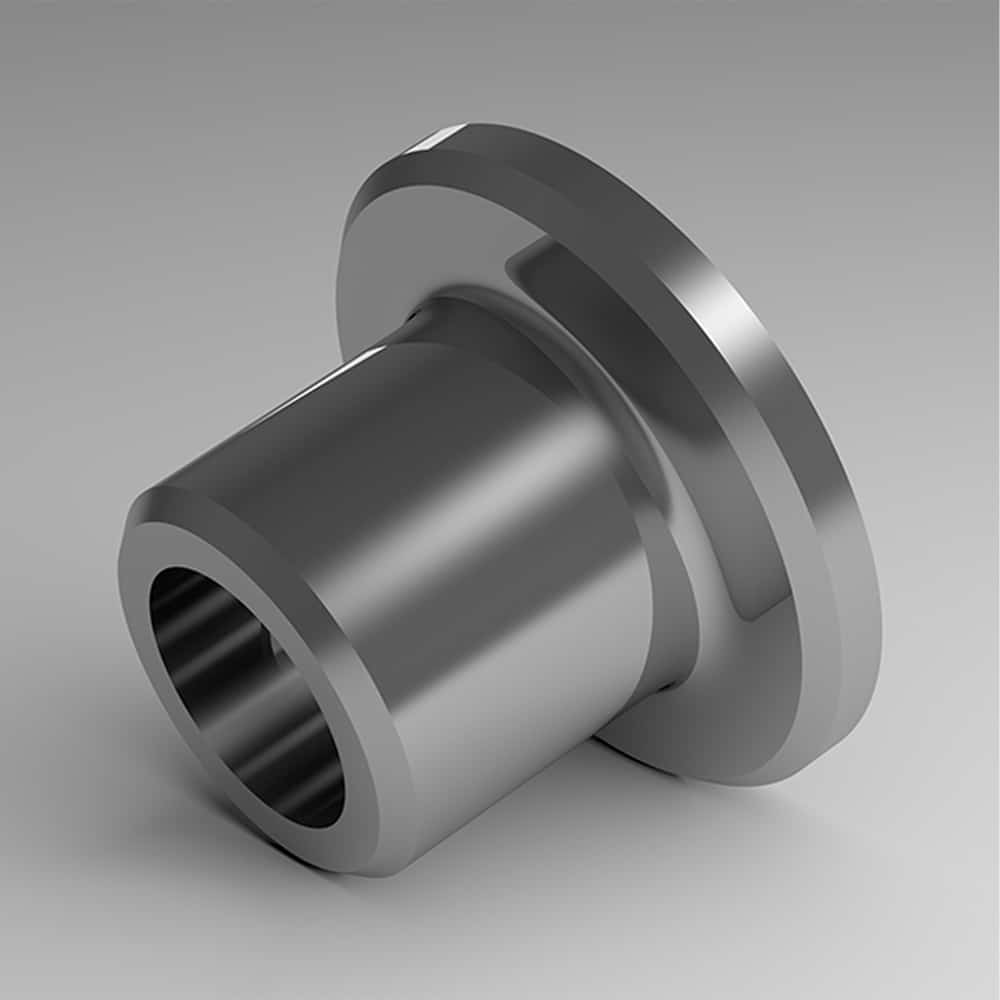

What Are Thrust & Flanged Bushings?

Thrust bushings (thrust washers) carry axial load between faces.

Flanged bushings are sleeve bushings with an integral flange that locates the bushing and/or

shares axial load while the cylindrical ID still supports radial load on the shaft.

They run in boundary/mixed lubrication much of the time; life depends on PV, materials, clearance, and surface finish.

Typical uses: linkages with end thrust, stop faces, indexing tables, actuators with axial reaction,

hinges and door mechanisms, conveyors (end thrust), packaging & food equipment (washdown), marine and outdoor hardware.

Selection Cheatsheet (Duty, PV, Geometry, Environment)

- Mostly axial load? Thrust washer or flanged bushing with adequate flange area; verify face pressure and torque.

- Combined load? Flanged bushing handles radial via ID and axial at flange; confirm both PV (ID) and face pressure (flange).

- Oscillation/start-stop? Favor PTFE/composite liners or polymers tuned for boundary regime.

- Sustained rotation? Use oil feed and groove pattern that doesn’t starve the loaded arc; consider bronze/babbitt.

- Environment drives materials: washdown → stainless + inert coatings; abrasive → hard low-roughness surfaces + seals.

- After coatings: re-measure ID/OD, flange thickness & flatness, face runout, and hot clearance.

Environment → Attributes Matrix

| Environment | Material / Surface | Clearance / Flatness | Fits (shaft / housing) | Sealing | Lubrication |

|---|---|---|---|---|---|

| Oscillating hinge with end thrust | PTFE/composite liner; hard chrome on pin & flange face | Nominal clearance; flange flatness critical for smooth torque | Pin h6–h9 / Housing H7 with OD interference to prevent spin | Deflectors or boots | Grease purge schedule; compatible with liner |

| Indexing table axial stop | Bronze/babbitt thrust washer; ground face; optional chrome | Face flatness/parallelism; runout <= torque spec | Clamped stack; anti-rotation features | Non-contact shields; chip guards | Oil feed or high-quality grease for stop impacts |

| Washdown / Food | Stainless shells; inert chrome or Ni-P on faces & pins | C3-like looseness concept if thermal rise; verify torque hot | k5–m6 / H7; confirm post-coat ID & flange thickness | Contact seals + deflectors; avoid jets at faces | H1 grease; purge after wash; dry-out routine |

| Dusty / Abrasive | Hard, low-roughness shaft & face coatings; wear-tolerant liners | Don’t over-tighten; allow film | Secure fits; add anti-rotation notch if needed | Labyrinth + shields; purge paths | Grease with sealing behavior; set purge interval |

| High temperature | High-temp polymers/composites or bronze/babbitt | Clearance for thermal growth; face flatness maintained hot | Thermal growth model for fits/clamp | Heat shields / non-contact seals | High VI oil or dry-film compatible liner |

Common Failures & Diagnostics

Rapid Triage

1) Thrust Face Wear / Grooving

Symptoms

Rising axial play, scratch rings on face, torque fluctuations.

Likely causes

Abrasive ingress, PV over limit, inadequate lubrication, face not flat/parallel.

Checks

Face flatness & runout; contamination paths; PV vs. catalog; groove design.

Non-coating actions

Improve sealing/guards; adjust grease/oil; redesign grooves; reduce load or speed.

When surface treatments help

Hard, low-roughness chrome on face reduces abrasion once ingress is controlled.

2) Seizure / Scoring (ID or face)

Symptoms

Squeal, heat spike, visible scoring on shaft or face.

Likely causes

Clearance too tight hot, viscosity too low, misalignment, overload.

Checks

Hot clearance; viscosity @ temp; face parallelism; alignment.

Non-coating actions

Resize clearance; raise viscosity/cooling; correct alignment; add grooves.

When surface treatments help

Low-roughness chrome reduces adhesion after clearance/lube are correct.

3) Fretting at Flange Seat / OD

Symptoms

Reddish oxide at OD or under flange, creak/squeak, micro-motion marks.

Likely causes

Insufficient interference or clamp; vibration; thermal cycles.

Checks

Fit classes; clamp torque sequence; seat finish; transport profile.

Non-coating actions

Increase interference/anti-rotation features; improve clamp and seat flatness.

When surface treatments help

Micro-textured chrome on seats lowers adhesion once fits are corrected.

4) Flange Cupping / Extrusion

Symptoms

Edge-high contact, uneven wear ring, flange deformation.

Likely causes

Face not supported; clamp over-torque; thermal gradients; polymer creep.

Checks

Seat flatness; clamp distribution; temperature map; material choice.

Non-coating actions

Improve backing washer/seat; adjust clamp; choose stiffer material.

When surface treatments help

Not primary; geometry/support dominates.

5) Stick-Slip / High Breakaway Torque

Symptoms

Jerky axial starts, audible squeak, inconsistent positioning.

Likely causes

Boundary regime with high μs/μk; incompatible grease; rough faces.

Checks

Grease chemistry; face finish; temperature; groove pattern.

Non-coating actions

Change grease; polish faces; adjust preload or dwell profile.

When surface treatments help

Low-roughness chrome reduces μ variance after lube/grooves are corrected.

The Big Three: Corrosion, Lubricity, Dimensional Stability

Use coatings when they address surface-driven issues (corrosion, fretting, abrasion) on pins/shafts, faces, and housing seats. Coatings don’t replace clearance control, alignment, sealing, or lubricant choice.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Protect faces, IDs/ODs, and pins from rust/chemicals | Seals/deflectors; wash angles; drying; compatible H1 grease | Thin dense/micro-cracked chrome or Ni-P on faces & pins | Re-measure ID and face flatness after processing |

| Lubricity | Reduce stick-slip under axial load and oscillation | Right grease/oil; groove design; PV within material limits | Low-roughness/micro-textured chrome on pins & faces | Coatings complement—don’t replace lubrication discipline |

| Dimensional stability | Keep clearance, flange thickness, and face runout in spec | Thermal model; rigid seats; correct clamp sequence | Controlled-thickness coatings; post-coat metrology | Small thickness shifts change torque & axial play |

Fits, Geometry & Axial Location (Quick Rules)

-

Pin/shaft fit: sliding fit for motion (e.g., h6–h9 vs. bushing ID). Finish Ra ≤ ~0.2–0.4 μm for liners.

-

OD/seat: prevent spin/fretting—use interference or anti-rotation features; seat flatness matters under the flange.

-

Flange face: perpendicular to bore; adequate thickness; support with a flat backing surface to avoid cupping.

-

Grooves & chamfers: add grease/oil pockets without starving loaded arc; chamfers clear shaft radii.

-

After coatings/linings: ream/hone to size; re-measure ID, flange thickness, face runout, and hot clearance.

Checklist

-

Seat flatness/parallelism verified

-

Hot clearance modeled/checked

-

Face runout & torque within spec

-

Post-process metrology complete

Frequently Asked Questions

Within its face area and material PV limit—verify face pressure and torque. For heavy axial duty, consider a dedicated thrust washer/bearing.

Only liners designed for dry running should run dry. Bronze/babbitt needs grease/oil; polymers vary—check the catalog.

Yes. Control thickness, then ream/hone IDs and re-measure flange thickness and face runout after coating.

Use proper OD interference, knurls/serrations, flats, or anti-rotation tabs; confirm clamp sequence.

Case Snapshots

- Indexing stop face wear — Bronze thrust washer grooved after packaging dust ingress.

Actions: added deflectors, switched to micro-textured hard chrome face + filtered oil feed; verified runout.

Outcome: torque stabilized; no new grooves after 6 weeks. - Washdown hinge stick-slip — PTFE-lined flanged bush squealed after sanitation cycles.

Actions: hard-chrome pins + H1 grease purge; added boots; validated cleaner pH; rechecked flange flatness.

Outcome: smooth start torque; reduced staining through audit period.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).