Steel-on-steel handles higher shock loads and is greaseable; maintenance-free reduces service but has lower PV/load limits.

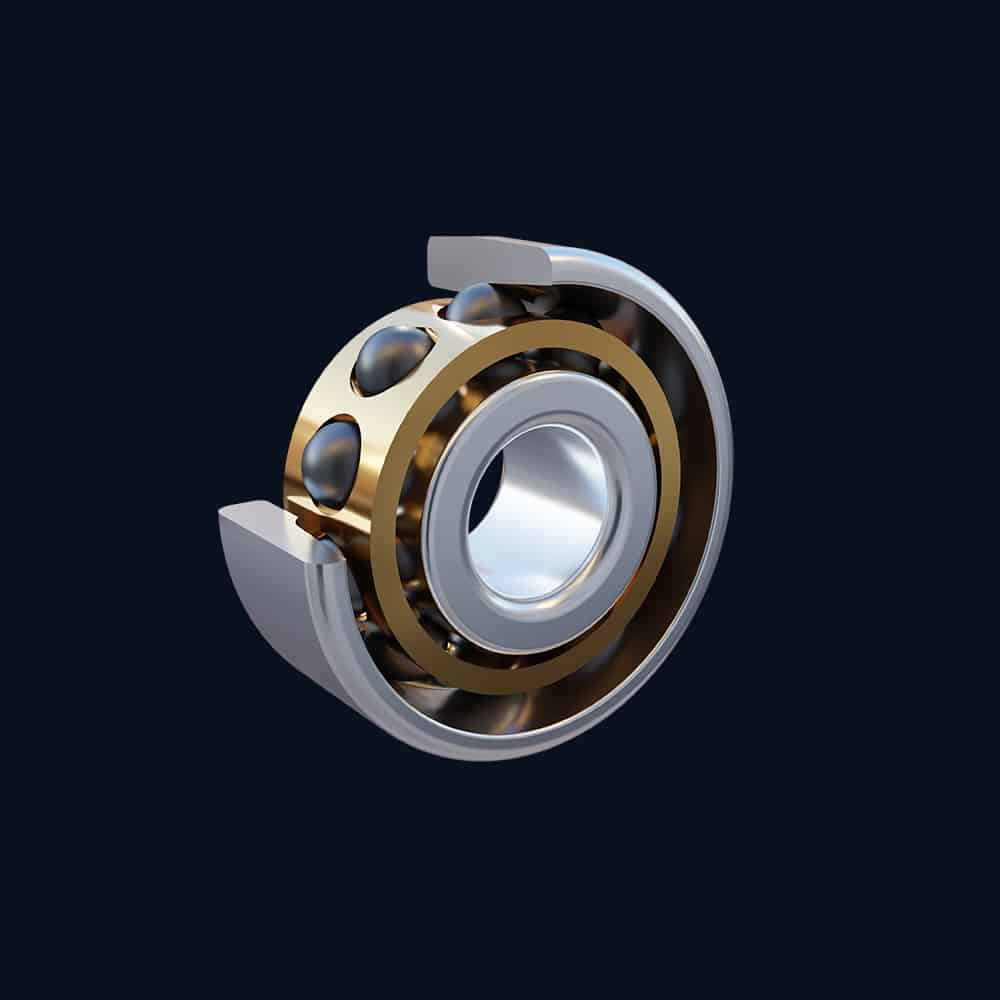

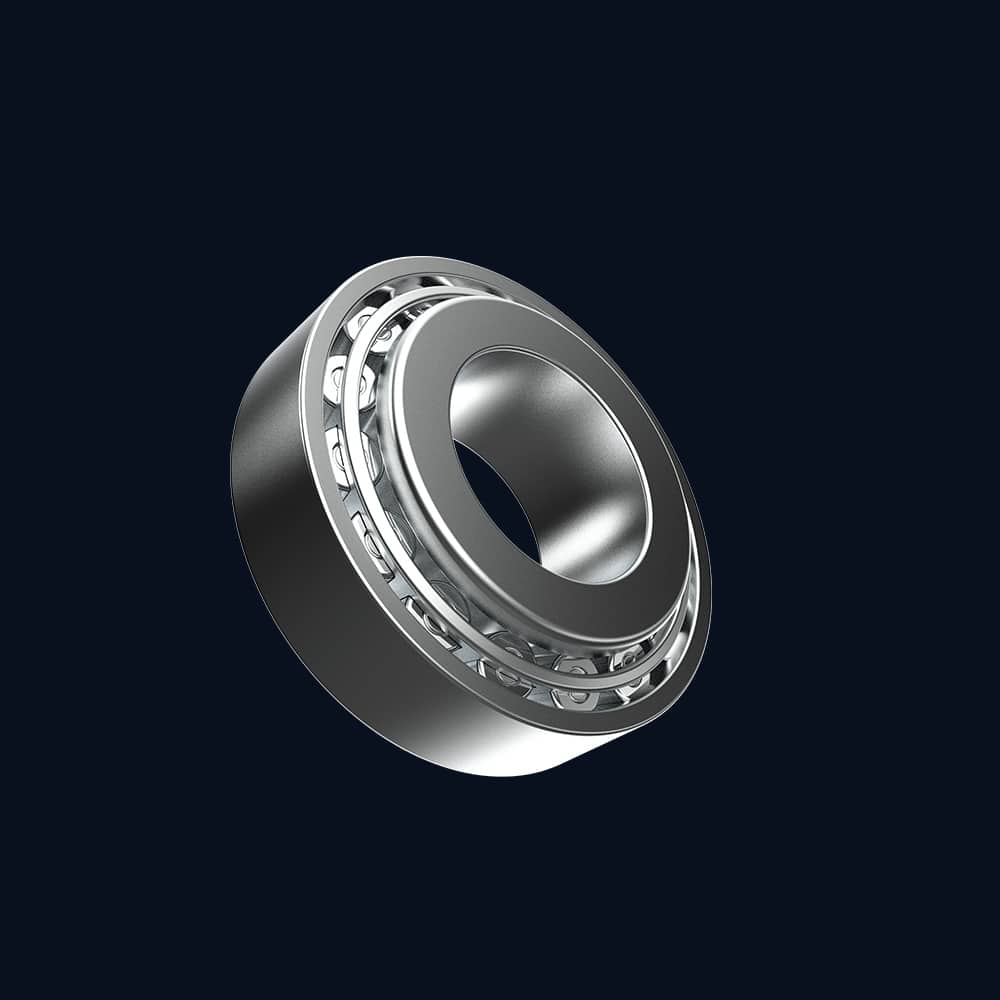

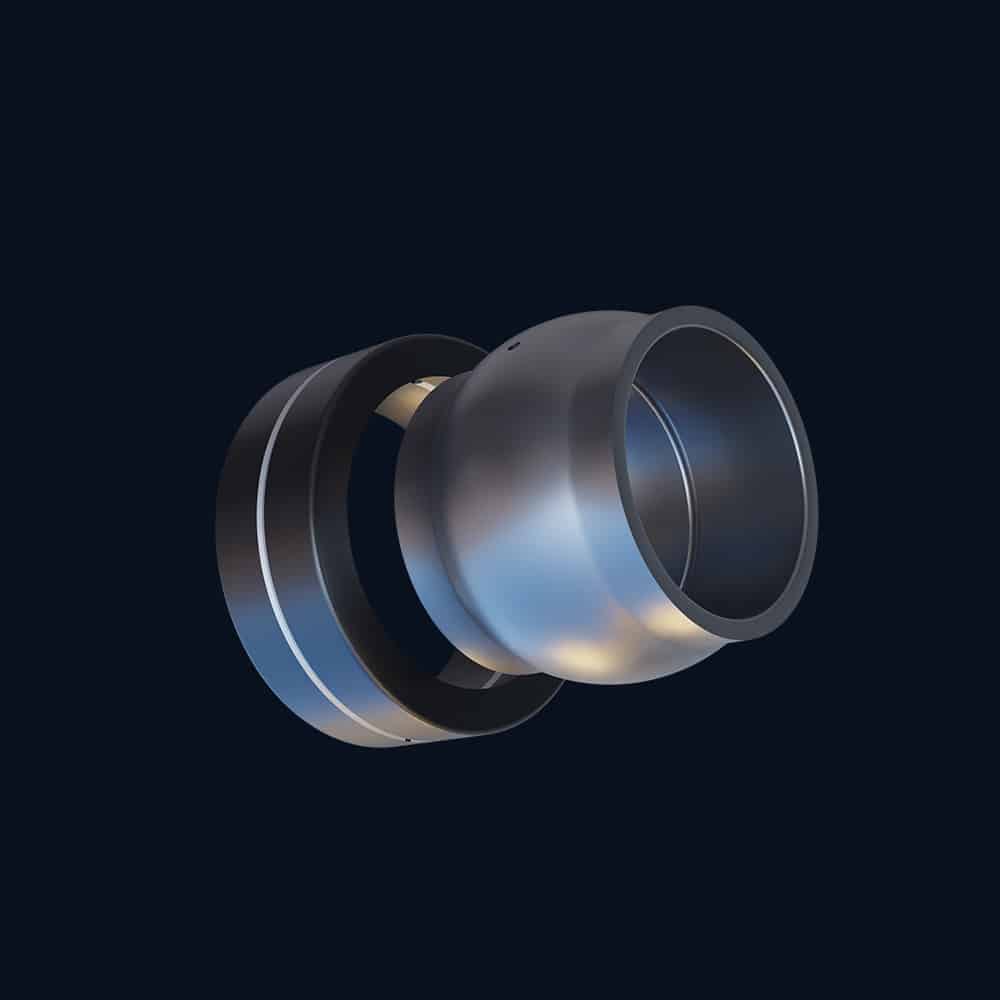

What Is a Spherical Plain Bearing (Radial + Rod Ends)?

A spherical plain bearing supports a pin/shaft with a spherical sliding contact—an inner ring (ball) with convex radius running in a concave outer ring. It carries primarily radial load and accommodates misalignment and oscillation. Rod ends integrate the bearing into a threaded eye for easy linkage mounting.

Typical uses: hydraulic cylinder ends, linkages and tie-rods, heavy equipment joints, robotics and cobot arms, packaging pick-and-place joints, vehicle suspensions, agricultural machinery, marine deck gear.

Selection Cheatsheet (Duty, Misalignment, Liner, Environment)

- Oscillation with shock? Steel-on-steel, greaseable; hardened pin; consider boots/wipers.

- Maintenance-limited or cleanroom? PTFE/composite maintenance-free liner; lower load ratings—check PV.

- High misalignment? Pick series with larger α (angle); or use spacers/clevis geometry to avoid edge loading.

- Corrosion risk? Stainless rings or steel with corrosion-resistant coatings; sealed rod ends; H1 grease where needed.

- Moment load present? Space bearings (or pair with rolling support) to carry overturning moment; SPBs alone are not moment bearings.

- After coatings: re-measure bore/pin diameters, sphericity, and torque; small thickness changes shift preload/clearance.

Environment → Attributes Matrix

| Environment | Material / Surface | Clearance & Fit | Sealing | Lubrication | Notes |

|---|---|---|---|---|---|

| Outdoor / Washdown | Stainless or coated rings; hard chrome on pins | Maintain running clearance after coating; pin h6–h9 typical | Boots/wipers; deflectors; protect seal lips from jets | H1 grease validated vs. cleaners/temps | Dry-out routine; avoid direct jetting at the spherical interface |

| Dusty / Abrasive | Hardened rings; wear-resistant surfaces; coated pins | Avoid too-tight fits that scrape liners | Labyrinth boots + shields | Grease with sealing behavior; purge schedule | Control ingress at clevis/eye gaps |

| Cleanroom / Vacuum | Stainless + passivated; maintenance-free liners | Low torque clearance; verify outgassing | Non-contact covers; particle control | Dry/liner operation or low-volatility lubricants | Avoid greases that shed or outgas |

| High Misalignment Hydraulics | High-angle series; robust liners or steel-on-steel | Check edge-loading; confirm clevis spacing | Boots; pin-side shields | Grease channels aligned to load path | Model axial float and stroke-induced moments |

| Corrosive / Marine | Stainless or chrome/Ni-P on rings & pins | Hold clearance after coating; confirm torque | Sealed rod ends; deflectors | Marine-grade grease; purge after spray | Rinse + dry-out; avoid galvanic couples |

Common Failures & Diagnostics

Rapid Triage

1) Corrosion / Ingress at Spherical Pair

Symptoms

Brown/red staining, rising breakaway torque, rough feel after washdowns.

Likely causes

Water/chemical ingress; incompatible cleaners; inadequate boots/wipers; purge neglected.

Checks

Seal/boot integrity; jet angles; grease compatibility; dry-out routine.

Non-coating actions

Add/repair boots; change wash strategy; use H1 grease; set purge cadence.

When surface treatments help

Hard, inert chromium-family or Ni-P reduces corrosion initiation on rings/pins.

2) Liner Wear / Delamination (Maintenance-free types)

Symptoms

Increasing radial play, torque spikes, flakes/debris from liner edge.

Likely causes

PV exceeded; edge loading from misalignment; abrasive ingress; heat.

Checks

PV vs. catalog; alignment (clevis spacing); particle control; operating temp.

Non-coating actions

Move to higher-PV liner or steel-on-steel; improve sealing; adjust geometry.

When surface treatments help

Low-roughness pins reduce adhesion and heat once PV is within spec.

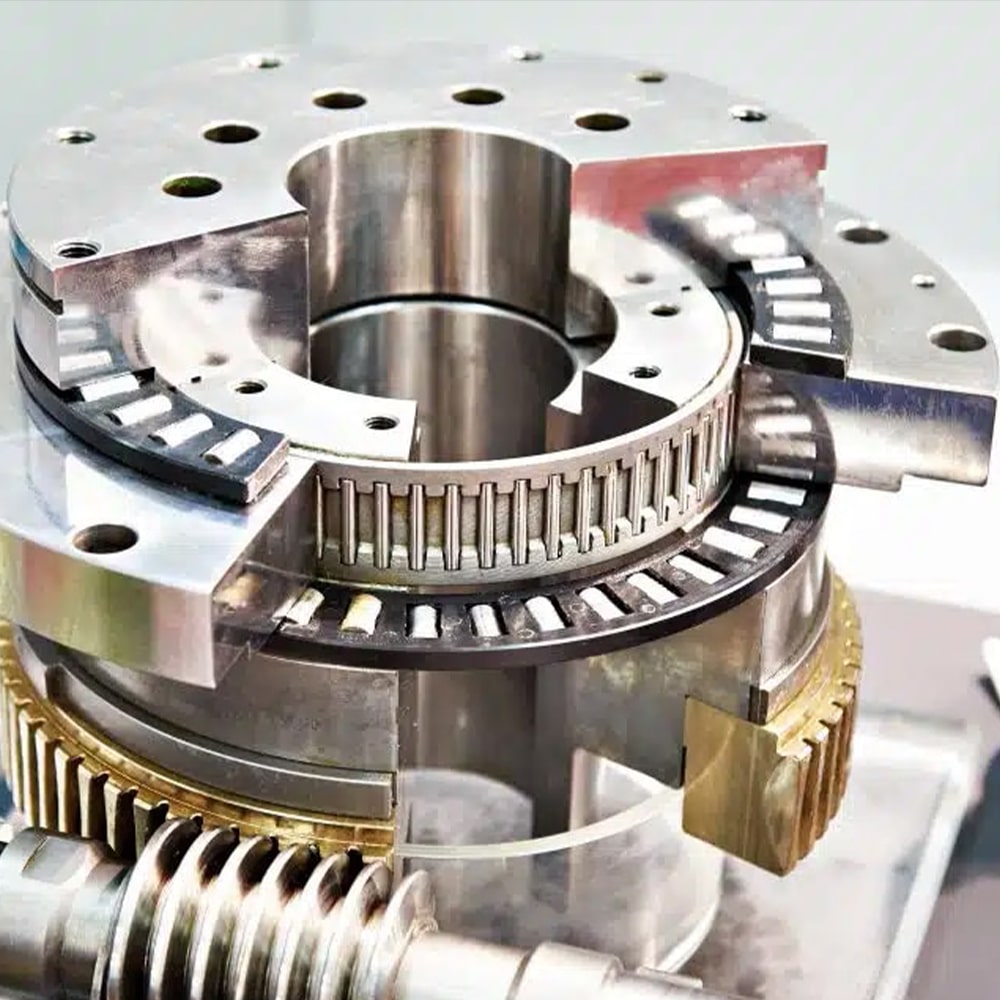

3) Fretting at Pin/Eye Seats

Symptoms

Reddish oxide at fit lines, creak/squeak, visible micro-motion marks.

Likely causes

Insufficient interference/clamp; vibration in idle; thermal cycles.

Checks

Fit class; torque audit; transport profile; surface hardness.

Non-coating actions

Increase interference/retention; stabilize transport; raise hardness.

When surface treatments help

Micro-textured chrome on pins/bores reduces adhesion after fit is corrected.

4) Brinelling / Impact Damage

Symptoms

Dents/flat spots on spherical surface; step in torque near dent angle.

Likely causes

Shock loading, mis-rigged cylinders, hammer assembly.

Checks

Load paths; stop design; assembly method; material hardness.

Non-coating actions

Add stops/buffers; upsize bearing; improve assembly procedure.

When surface treatments help

Hard, tough surfaces can improve dent resistance but won’t save under gross overload.

5) Stick-Slip / High Breakaway Torque

Symptoms

Jerky starts, audible squeak, positional overshoot in robots.

Likely causes

Boundary regime with high μs/μk ratio; low-bleed grease; rough pins.

Checks

Grease chemistry; pin finish (Ra); temperature; liner type.

Non-coating actions

Change grease; polish pins; select liner with lower μ or add preload control.

When surface treatments help

Low-roughness chrome on pins reduces μ variance once lube/liner are correct.

The Big Three: Corrosion, Lubricity, Dimensional Stability

Apply coatings when they address surface-driven issues (corrosion, fretting, abrasion) on pins, eyes, and bearing rings. Coatings don’t replace proper clearance, alignment, sealing, or grease choice.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Prevent rust/pitting on spherical pair and pin/eye | Seals/boots; wash angles; drying; grease compatibility | Thin dense or micro-cracked chrome; Ni-P; validated stainless | Re-measure torque/clearance after processing |

| Lubricity | Low stick-slip under oscillation; good film retention | Correct grease viscosity; purge plan; liner choice for duty | Low-roughness or micro-textured chrome on pins/seats | Coatings complement—don’t replace grease or liner selection |

| Dimensional stability | Hold sphericity/clearance and assembly torque | Flat/parallel faces; correct fits; thermal model | Controlled-thickness coatings; post-coat metrology | Small thickness shifts change torque and misalignment capacity |

Fits, Axial Location & Misalignment (Quick Rules)

-

Pin fit: keep a sliding fit for rotation/oscillation (e.g., pin h6–h9 vs. bearing bore). Harden pin & finish Ra ≤ ~0.2–0.4 μm for liners.

-

Housing/eye fit: prevent creep—use interference or threaded rod ends; verify clamp sequence so the outer ring is fixed.

-

Misalignment budget: stay within catalog angle; use spacers/clevis geometry to avoid edge loading.

-

After coatings: re-check bore/pin size, sphericity, axial locating faces, and starting torque.

Checklist

-

Pin hardness/finish verified

-

Housing interference or thread engagement set

-

Misalignment angle within series limit

-

Post-coat torque/clearance measured

Frequently Asked Questions

Series-dependent (often ±5–15°). Exceeding this edge-loads the liner/race—upsize or adjust geometry.

Coatings can meet many corrosion goals at lower cost, but validate chemistry and re-measure torque/clearance.

Ingress or corrosion, degraded grease, liner wear, or post-coat clearance change. Inspect seals, chemistry, and geometry.

Choose based on packaging. Consider left-hand threads to maintain adjustment under load reversals.

Case Snapshots

- Cylinder clevis corrosion — Breakaway torque rose after sanitation cycles.

Actions: sealed rod ends + boots, switched to H1 grease, hard-chrome pins; validated cleaner chemistry.

Outcome: stable torque; no staining over 3 months. - Robot wrist stick-slip — Overshoot at low angles with PTFE-lined joints.

Actions: polished pins, changed to compatible low-shear lube, added light preload control.

Outcome: smoother starts; reduced position error.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).