Armoloy Specifications

What is ASTM B650?

ASTM B650 is a standard specification for engineering-grade hard chromium coatings applied to ferrous alloy surfaces through electrodeposition. Unlike decorative chrome, these coatings are thicker and designed for durability, making them ideal for improving wear resistance, reducing friction, protecting against corrosion, and restoring undersized or worn parts.

The standard classifies coatings into two thickness categories:

Class 1: 2.5 to 25 µm for light-duty applications.

Class 2: Greater than 25 µm for heavy-duty applications.

ASTM B650 creates a structured approach to hard chromium plating, ensuring every coating meets exact engineering requirements, regardless of application. By regulating thickness, adhesion, and performance characteristics, ASTM B650 eliminates guesswork and gives manufacturers confidence in every plated component.

Beyond quality control, ASTM B650 also integrates safety and environmental considerations, aligning plating operations with industry best practices. For applications where failure isn’t an option—like oil and gas extraction, injection molding, and hydraulic pumps—this standard ensures components perform reliably under extreme conditions.

The Role of ASTM B650 in Electrodeposited Engineering Chromium

ASTM B650 contributes to hard chromium plating in several key ways:

- Supports High-Precision Applications: Class 1 coatings down to 2.5 µm are ideal for parts that require tight tolerances and smooth movement.

- Simplifies Part Repair and Rebuilds: Standardized thickness and adhesion criteria help restore worn or undersized components to spec.

- Standardizes Processes: Establishes uniform testing and application methods, helping engineers and finishers achieve consistent results.

- Mitigates Safety Risks: Requires post-plating heat treatments to reduce hydrogen embrittlement in high-strength steel parts.

Engineers and finishers rely on ASTM B650 to produce durable, high-quality hard chrome coatings for demanding industries.

ASTM B650 Testing Methodology & Results

ASTM B650 outlines strict testing methods to verify hard chromium coatings’ strength, reliability, and consistency. Key tests include:

- Thickness Measurement: Uses methods like microscopy, magnetic testing, coulometry, and X-ray spectrometry to confirm coatings meet Class 1 or Class 2 thickness standards.

- Adhesion Testing: Bend, file, push, and heat-quench tests check that coatings stay bonded to the surface without peeling, flaking, or delaminating.

- Porosity and Corrosion Testing: Ferroxyl, salt spray, and copper sulfate tests help identify tiny pores or defects that can lead to corrosion.

- Hydrogen Embrittlement Prevention: Pre-plating heat treatments reduce residual stress, while post-plating baking strengthens high-strength steels and prevents brittleness.

These tests simulate real-world challenges so coatings perform as expected where it matters most.

Industries that Rely on ASTM B650

ASTM B650 is critical in industries that demand precision, strength, and long-lasting protection for ferrous components. These coatings are essential in:

- Aerospace: Reduces friction and enhances wear resistance in landing gear, engine parts, and hydraulic systems.

- Automotive: Increases durability in piston rings, brake rotors, and transmission components, improving performance and reducing maintenance.

- Machined Components: Provides precise, wear-resistant coatings to extend the life of high-precision industrial parts.

- Oil and Gas: Protects drilling tools, pipelines, and valves from corrosion and wear in harsh environments.

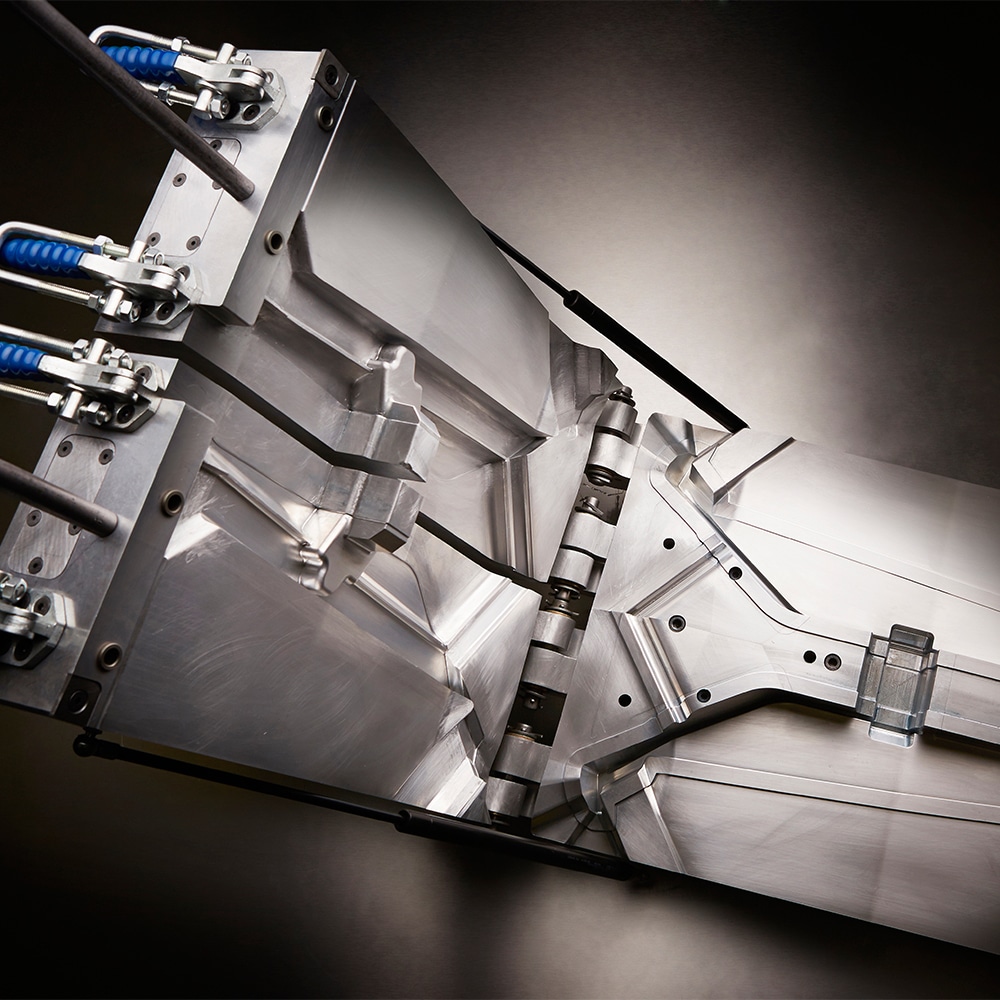

- Injection Molds: Strengthens molds, dies, and cutting tools, maintaining precision in high-stress manufacturing settings.

From hydraulics to high-speed tooling, manufacturers in these sectors rely on ASTM B650 for consistent plating, part protection, and operational efficiency.

Benefits of Working with an ASTM B650 Provider

Turnkey partnership

Work with experts who guide you through the entire process, from material selection to final delivery, ensuring seamless project execution

Durable coating solutions

Compliant coatings deliver exceptional wear and abrasion resistance, extending component life and reducing replacements

Performance optimization

Enhance equipment functionality with coatings that minimize friction, galling, and corrosion

Predictable maintenance

High-quality coatings reduce unexpected failures, making maintenance more predictable and cost-effective

Regulatory confidence

ASTM B650 providers support compliance with industry regulations worldwide

Precision restoration

Restore undersized or worn parts with coatings that meet stringent engineering requirements, reducing material waste

Consistent quality

Standardized plating processes ensure repeatable, high-performance coatings across every batch

Risk mitigation

Comprehensive testing verifies that coatings meet strict quality standards, minimizing the chance of failures

Specifications at Armoloy

Armoloy offers plating solutions that meet ASTM B650 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to ASTM B650, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of ASTM B650 within its own processes and does not constitute official or authorized guidance from ASTM International.

ASTM B650 is a proprietary standard developed and owned by ASTM International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. References to ASTM B650 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized engineering chromium plating standards.

This content is not intended to substitute for the official specification, which should be obtained directly from ASTM International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.