Armoloy Specifications

What is AMS 2460?

AMS 2460 is a specification from the SAE Aerospace Material Specifications (AMS) Committee that defines the requirements for electrodeposited chromium plating. This standard is widely used in aerospace, automotive, and commercial industries, ensuring plated components meet stringent performance and aesthetic requirements. The current revision, AMS 2460B, is based on similar requirements to the now-canceled AMS-QQ-C-320B but is generally more stringent.

The standard categorizes chromium plating into two main classes:

Class 1 - Decorative: Used in applications where corrosion protection and visual aesthetics are key. These coatings are typically thinner and available in bright (Type I) and satin (Type II) finishes. Testing focuses on surface appearance and corrosion resistance.

Class 2 - Engineering: Designed for functional performance in high-stress or wear-intensive environments. This type of plating is thicker and harder, offering wear resistance, reduced friction, and abrasion protection. Testing emphasizes mechanical integrity and durability.

AMS 2460 provides precise specifications for plating thickness, adhesion, and surface finish, balancing form and function to meet the needs of diverse applications.

The Role of AMS 2460 in Electrodeposited Chromium Plating

AMS 2460 sets the industry standard for hard chromium plating, ensuring components meet the highest quality, durability, and performance levels. Its key contributions include:

- Defining Quality Standards: Covers tests for coating thickness, adhesion, hardness, surface finish, porosity, and other factors for consistent, high-performance plating.

- Maximizing Wear Resistance: Produces tough, abrasion-resistant coatings that extend component lifespan in demanding conditions.

- Balancing Form and Function: Combines durability and wear resistance with a refined surface finish, supporting both practical and aesthetic requirements.

- Supporting Industry Compliance: Aligns with industry specifications and certification requirements, streamlining approval processes.

AMS 2460 provides the technical foundation for high-performance chromium plating, guiding manufacturers in producing coatings that meet the toughest operational demands.

AMS 2460 Testing Methodology & Results

AMS 2460 includes a variety of tests to confirm that chromium plating meets functional and aesthetic requirements. Some of the tests performed under AMS 2460 include:

- Thickness Test (Class 1 & 2): Verifies the coating’s thickness to ensure it meets AMS 2460 specifications for both decorative and functional applications.

- Adhesion Test (Class 1 & 2): Confirms the coating is bonded to the substrate.

- Hardness Test (Primarily Class 2): Measures the plating’s hardness to confirm its resistance to deformation.

- Visual Inspection (Class 1 & 2): Assesses surface appearance for uniformity, brightness, and other aesthetic or functional needs.

- Porosity Test (Primarily Class 1): Evaluates the coating for microscopic pores that could allow corrosion.

- Hydrogen Embrittlement Test (Class 2 only): Confirms the plating process does not weaken high-stress components due to hydrogen absorption.

Additional tests may apply based on the application and material, helping deliver consistent quality and performance whether used for decorative or engineering purposes.

Industries that Follow AMS 2460

AMS 2460 is vital for industries that rely on high-quality chromium plating for functional and decorative applications. Key sectors include:

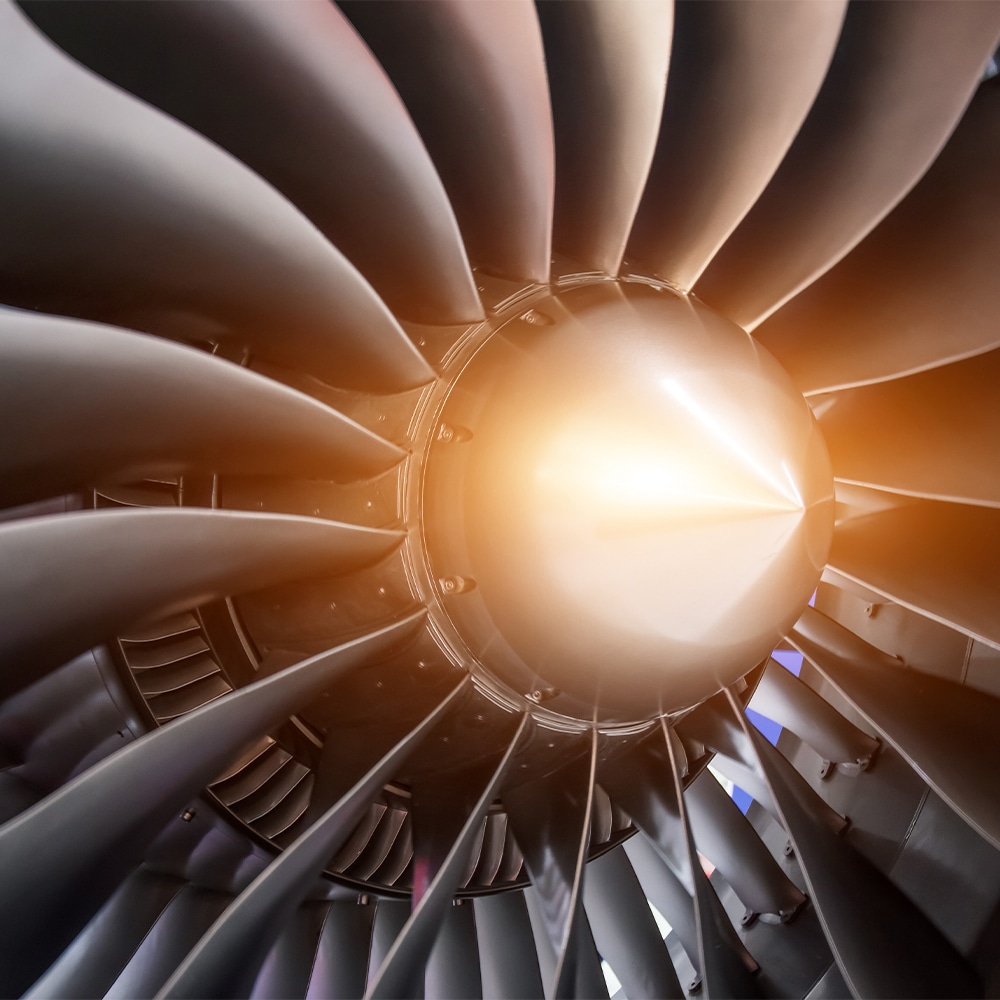

- Aerospace: Used for critical components such as landing gear, engine parts, and hydraulic systems.

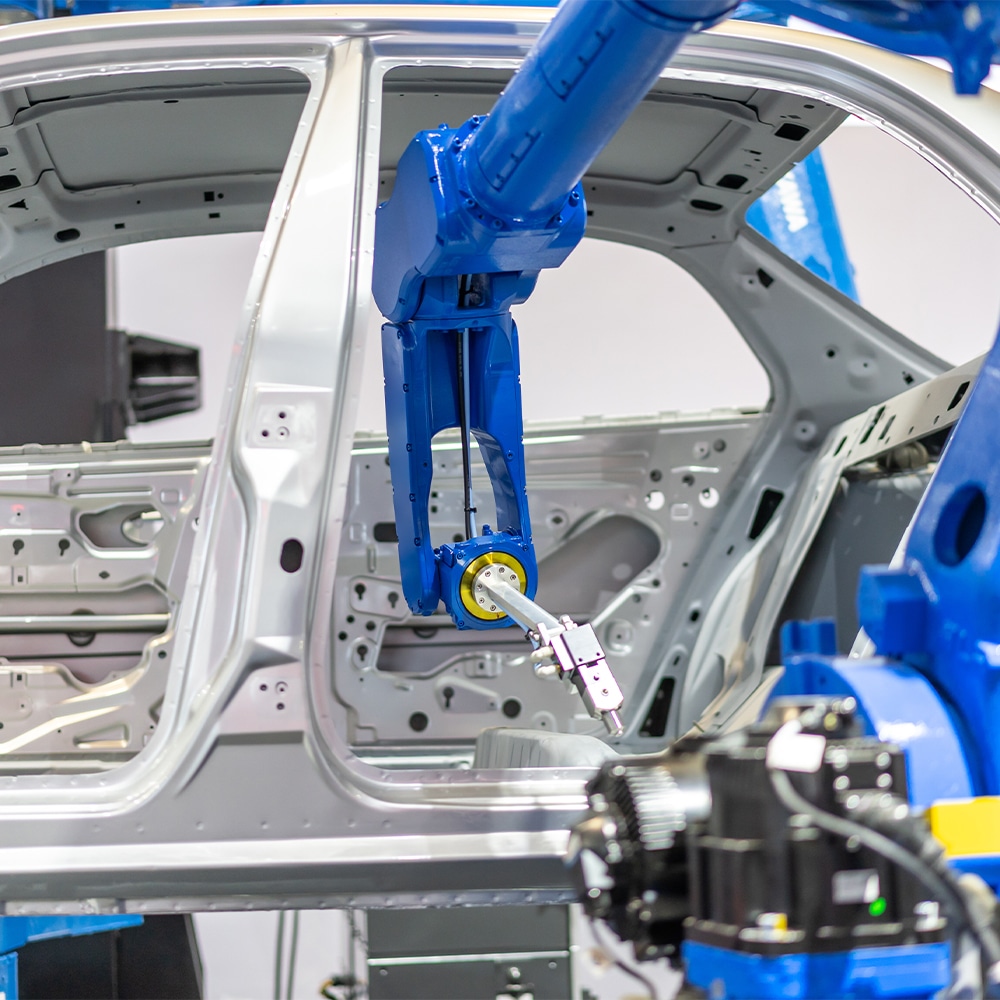

- Automotive: Ensures corrosion protection, aesthetic finishes for trim pieces, and wear resistance for engine and transmission components.

- Defense: Provides durable coatings for military equipment and weaponry.

- Oil and Gas: Protects drilling equipment, valves, and pipelines from harsh environments.

- Injection Molds: Enhances the longevity and performance of molds, dies, and other precision tools.

These industries depend on AMS 2460 to ensure their components meet durability, performance, and appearance requirements.

Benefits of Working with an AMS 2460 Provider

Consistent quality standards

Providers meet criteria for thickness, hardness, adhesion, porosity, hydrogen embrittlement, and surface finish, ensuring consistent results

Enhanced durability

Components plated to AMS 2460 standards resist wear, corrosion, and abrasion, extending their service life and reducing maintenance needs

Dual applications

Providers deliver solutions for both decorative and engineering applications, meeting the needs of industries requiring aesthetic finishes or high-performance coatings

Thorough testing

AMS 2460 mandates thorough testing protocols, ensuring all coatings meet stringent quality and performance benchmarks

Regulatory compliance

Providers that adhere to specifications help manufacturers meet industry standards and regulatory requirements

Tailored solutions

Providers can adjust plating parameters to suit functional or decorative requirements while staying within specification limits

Documentation and traceability

Providers maintain comprehensive records, offering transparency and traceability to support audits and specification compliance

Expertise and reliability

Providers bring extensive experience and technical knowledge, ensuring accurate results and dependable performance for critical components

Specifications at Armoloy

Armoloy offers plating solutions that meet AMS 2460 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information presented on this page, including any descriptions, interpretations, or summaries related to AMS 2460, is provided solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of AMS 2460 within its own processes and does not constitute official or authorized guidance from SAE International.

AMS 2460 is a proprietary standard developed and owned by SAE International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. Any reference to AMS 2460 is made in accordance with fair use principles and is intended to illustrate Armoloy’s alignment with widely recognized plating standards.

This content is not intended to substitute for the official specification, which should be obtained directly from SAE International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.