Armoloy Accreditations

What is Nadcap®?

Nadcap® (National Aerospace and Defense Contractors Accreditation Program) is the leading accreditation for aerospace and defense manufacturing. Developed by the Performance Review Institute (PRI), it establishes strict requirements to ensure special processes, such as chrome plating, meet industry standards for safety, reliability, and performance.

Unlike general quality certifications, Nadcap is an industry-managed accreditation developed by aerospace manufacturers, suppliers, and government representatives. It provides a standardized approach to process validation, ensuring that all accredited suppliers meet industry-defined requirements—not just regulatory minimums.

By eliminating redundant audits, Nadcap streamlines compliance and creates a single, recognized standard for aerospace and defense contractors.

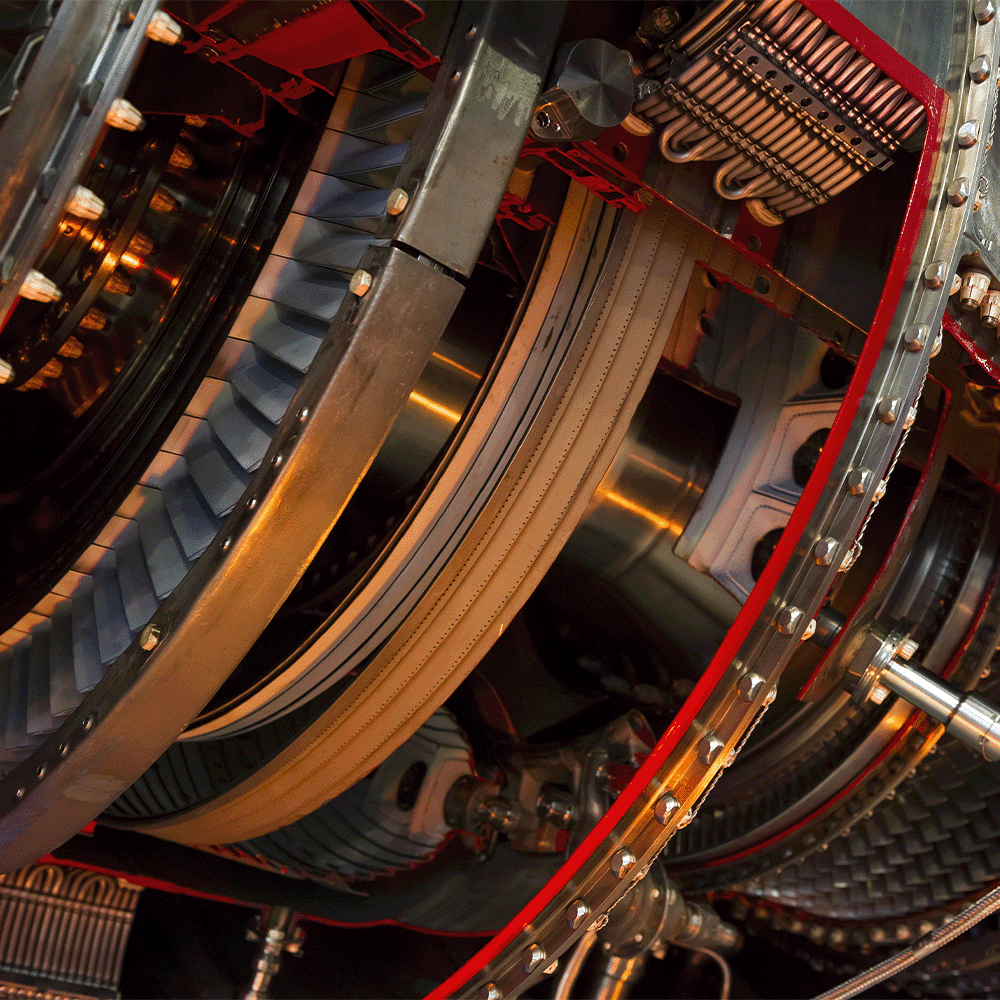

In aerospace and defense, precision is critical. Every plated component must perform flawlessly under extreme conditions, from high temperatures to intense mechanical stress. As a Nadcap-accredited provider, Armoloy ensures its chrome plating processes meet the highest aerospace standards, with strict process controls, traceability, and continuous quality monitoring. This level of oversight reduces inconsistencies, mitigates risk, and guarantees performance in mission-critical applications.

Core Principles of Nadcap®

Nadcap accreditation is founded on key principles that ensure consistency, reliability, and accountability in aerospace and defense manufacturing:

- Industry-Led Oversight: The industry experts and government representatives who rely on aerospace components set Nadcap’s policies. Manufacturers, suppliers, and regulatory bodies define and enforce their standards.

- Standardized Audits: One audit, one universal standard. Nadcap eliminates redundant assessments, ensuring every supplier meets the same strict criteria.

- Process Validation: It’s not just about the final product. Nadcap verifies how components are made, ensuring precision in every step—bath chemistry, plating thickness, and beyond.

- Risk Mitigation: By enforcing rigorous process controls, Nadcap prevents defects before they happen, protecting lives and multimillion-dollar equipment.

- Continuous Improvement: Regular audits push suppliers to refine and advance their processes, keeping pace with industry demands.

These principles collectively contribute to higher quality and efficiency in aerospace components.

Nadcap® Requirements for Chrome Plating

Many aerospace OEMs require coating providers to hold AS9100D certification, which includes ISO 9001:2015, as part of their supplier qualification process. While not a formal requirement for Nadcap, this certification supports a structured, consistent approach to quality that aligns with Nadcap’s audit expectations.

To earn Nadcap accreditation, coating providers must meet detailed process and quality control requirements, including:

- Process Control: Plating baths must be precisely maintained, with chemistry, temperature, and current density monitored for uniform, defect-free coatings.

- Material Testing: Adhesion, hardness, and thickness tests verify durability and compliance.

- Chemical Analysis: Regular testing ensures plating solutions remain stable, preventing defects.

- Documentation & Traceability: Every process detail is recorded for full transparency and audit compliance.

- Operator Training: Only qualified personnel handle plating to maintain industry standards.

Suppliers must also undergo regular Nadcap audits and demonstrate ongoing process enhancements.

Nadcap® Certification Areas

Nadcap subscribers, including major aerospace OEMs, establish standardized audit criteria to ensure consistent quality across the aerospace supply chain. The program accredits suppliers performing special processes critical to product safety and performance, including:

- Chemical Processing: This includes anodizing, chemical cleaning, and conversion coatings.

- Coatings: Applications such as plating, heat treating, vapor deposition, and paint.

- Heat Treating: Processes including annealing, hardening, tempering, and stress relieving.

- Non-Destructive Testing (NDT): Techniques like liquid penetrant, magnetic particle, ultrasonic, and radiographic inspections.

As an accredited Nadcap provider, Armoloy delivers coating solutions that meet aerospace-grade precision, consistency, and durability.

Benefits of Working with a Nadcap-Certified Provider

Supply chain approval

Nadcap certification streamlines supplier approval with major aerospace OEMs and contractors

Risk reduction

Nadcap oversight minimizes process failures, cutting down on escapes, rework, and warranty costs

Regulatory compliance

Meets FAA, DoD, and global aerospace requirements, reducing the need for additional audits

Enhanced traceability

Comprehensive documentation supports audits and accountability

Streamlined procurement

Reduces the need for redundant audits and qualifications, making supplier selection more efficient

Continuous improvement

Regular audits drive process advancements and keep suppliers ahead of industry standards

Competitive advantage

Certification opens doors to new contracts and partnerships, as many aerospace companies require it

Cost savings

Standardized processes reduce variability, waste, and inefficiencies, lowering production costs

Accreditations at Armoloy

Armoloy is Nadcap-certified and accredited to AS9100D and ISO 9001, ensuring compliance with the highest aerospace and defense standards. Contact us to find the optimal plating solution for your application.

Disclaimer: The interpretations and overviews of Nadcap® certification for chrome plating provided by The Armoloy Corporation are solely the views of Armoloy and may not represent the views of other entities. These interpretations are intended for informational purposes only and should not be considered as definitive or legally binding. The Armoloy Corporation is not responsible for the accuracy of these interpretations and expressly disclaims any liability for loss or damage arising from their use. This disclaimer is subject to change and does not create any express or implied warranty regarding the information provided.