Uncoated metal surfaces can demonstrate moderate to high friction, particularly in dry metal-on-metal applications. The actual level of friction depends on a variety of factors that influence surface interaction and resistance to motion:

- Surface Texture: Rough or unfinished metals increase friction due to greater surface asperity contact, while polished or treated metals reduce it.

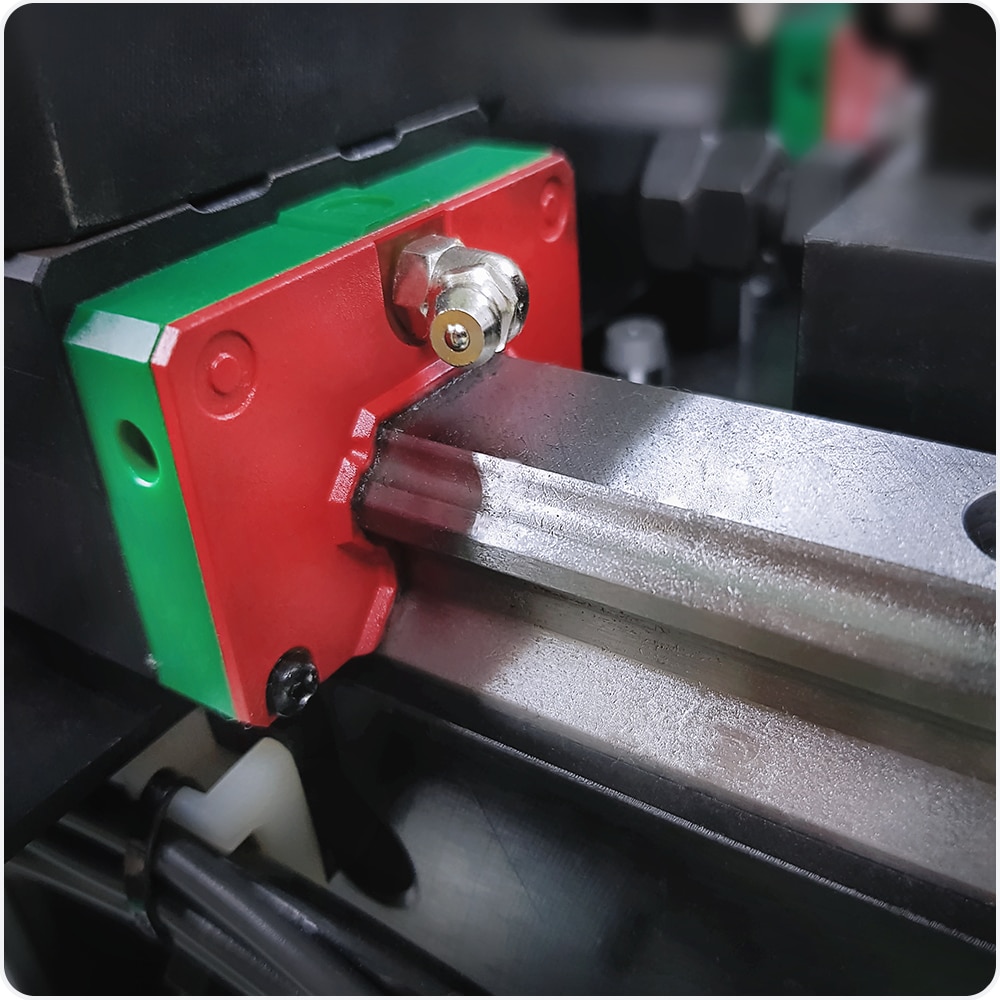

- Presence of Lubricants: Lubrication—using oil, grease, or dry-film lubricants—can drastically reduce the friction coefficient. Advanced coatings like Thin Dense Chrome (TDC) are also effective at minimizing friction under load.

- Material Combinations: Similar metals in contact (e.g., steel-on-steel) typically produce more friction than dissimilar pairings like metal-on-polymer or metal-on-ceramic.

- Operating Conditions: Factors like temperature, humidity, oxidation, or contamination can alter surface behavior and increase or reduce friction over time.

For perspective, the dry coefficient of friction for untreated steel-on-steel may range from 0.5 to 0.8. With proper lubrication or coatings, this value can drop below 0.1—critical for reducing wear and energy loss in industrial applications like bearings, actuators, molds, and sliding systems.