Yes — selecting incompatible metal combinations can accelerate both fretting wear and galvanic corrosion, leading to surface damage and material loss in pairings like these:

- Aluminum with Copper or Brass: Aluminum is anodic to copper, making it highly prone to corrosion when combined under vibration or mechanical load.

- Steel with Zinc or Galvanized Components: The zinc layer breaks down quickly when paired with steel under cyclic motion.

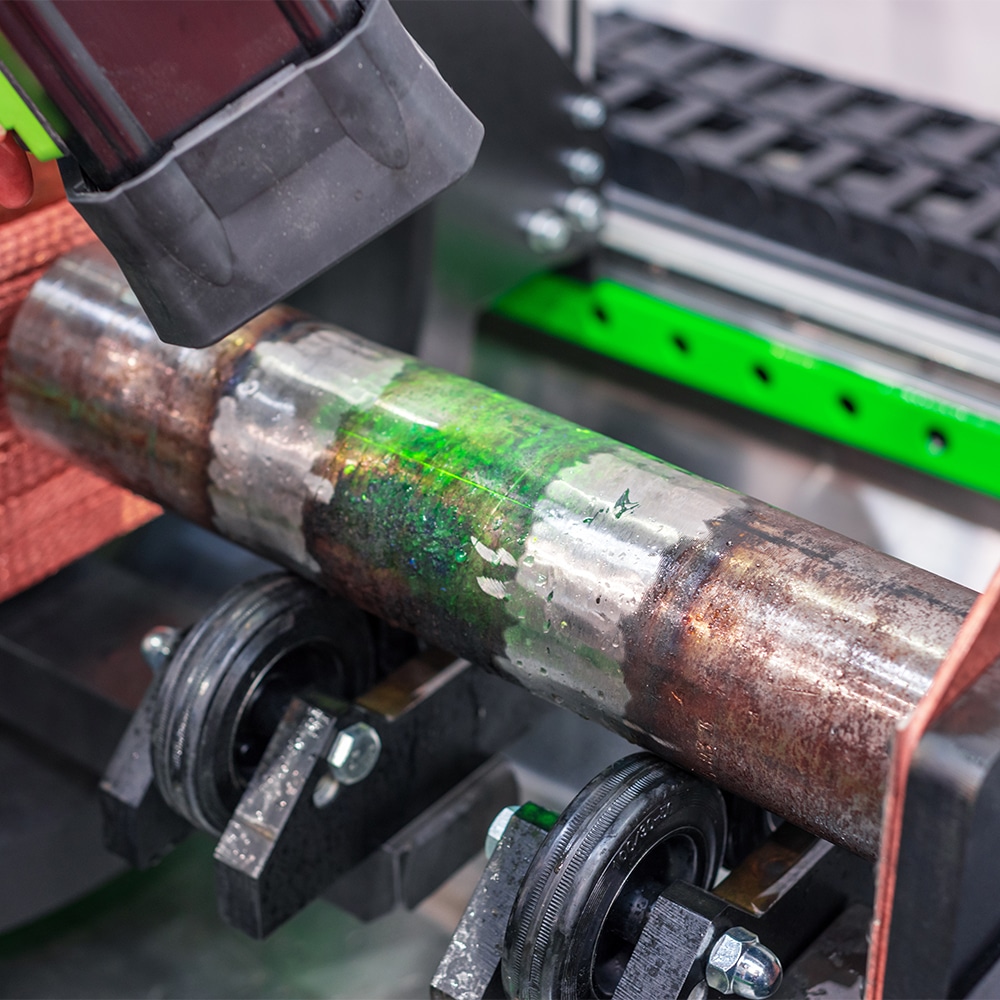

- Stainless Steel with Carbon Steel: Micromotions between these metals can trigger fretting corrosion, especially in moist or loaded joints.

- Magnesium with Other Metals: Magnesium’s extreme anodic nature makes it highly vulnerable when contacting dissimilar metals under friction.

- Steel with Bronze or Brass: Repeated micro-movement in these pairings encourages fretting wear and galvanic reactions.

Prevention tips for fretting and corrosion in mixed metals:

- Use compatible metals with similar electrochemical properties.

- Apply hard surface coatings or platings to reduce friction and isolate contact.

- Use vibration dampers, lubricants, or flexible joints to limit micro-movement.

Avoid incompatible metal pairings, particularly in parts exposed to vibration or load, to reduce the risk of fretting and corrosion.