Cavitation can silently damage metal surfaces over time, so spotting early warning signs is essential for preventing costly failures in pumps, turbines, and fluid-handling equipment.

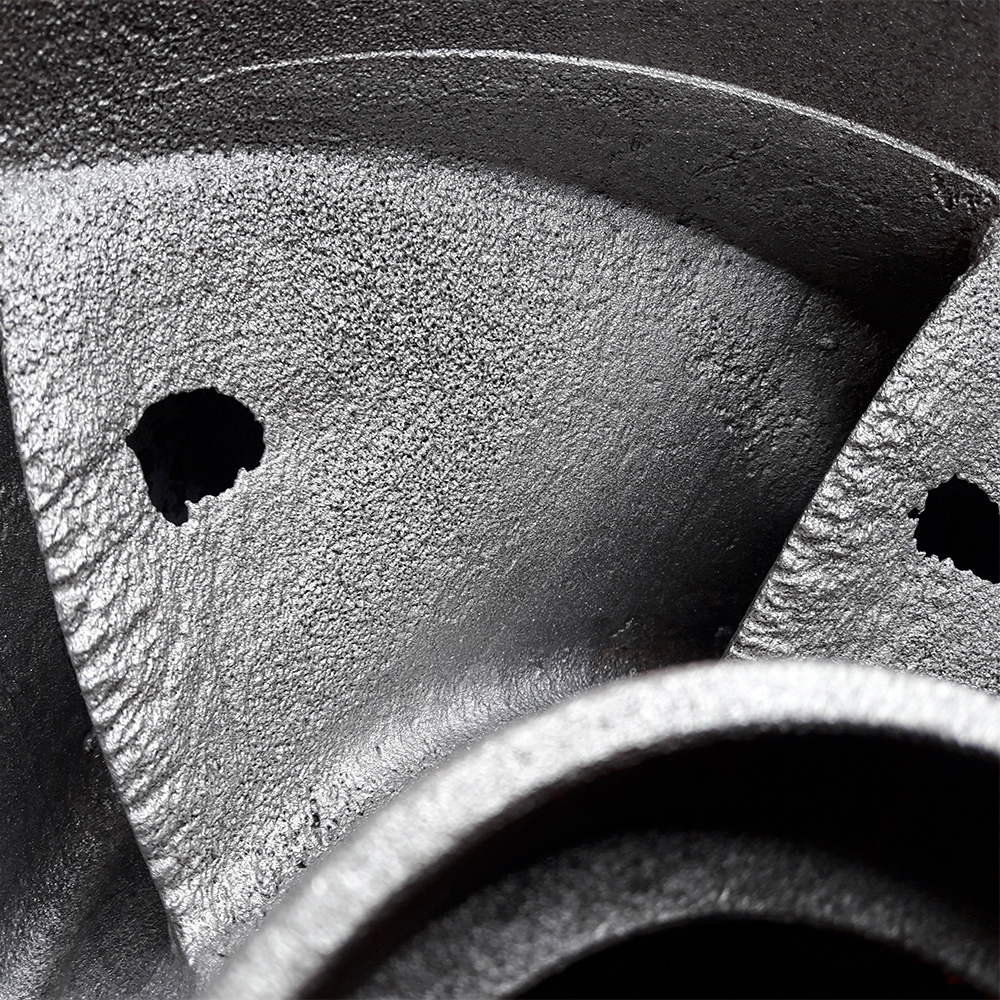

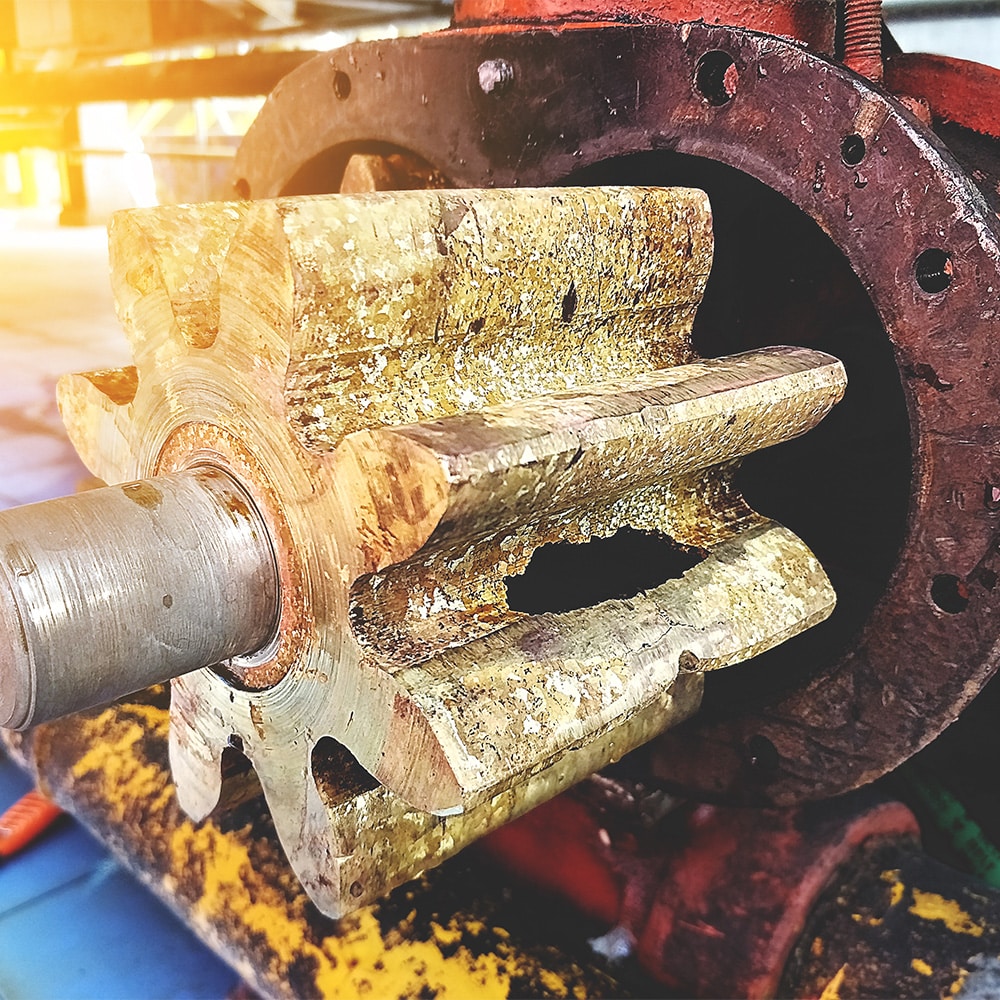

- Surface Pitting: Tiny, crater-like holes or rough patches often appear on impellers, valves, or propellers — usually in high-velocity or low-pressure zones.

- Unusual Vibration or Noise: Cavitation often causes a “rumbling” or “gravel-like” sound inside pumps or flow systems, along with abnormal vibration.

- Drop in Performance: A sudden loss in flow rate, pressure, or efficiency may indicate cavitation is disrupting normal fluid dynamics.

- Localized Erosion: Cavitation can accelerate wear in specific areas, especially downstream of flow restrictions or sharp turns in piping systems.

Routine inspections and monitoring for these symptoms help catch cavitation damage early — before it leads to severe pitting, metal fatigue, or total part failure.