Wear is a common failure mode in mechanical systems, and it generally falls into four key categories:

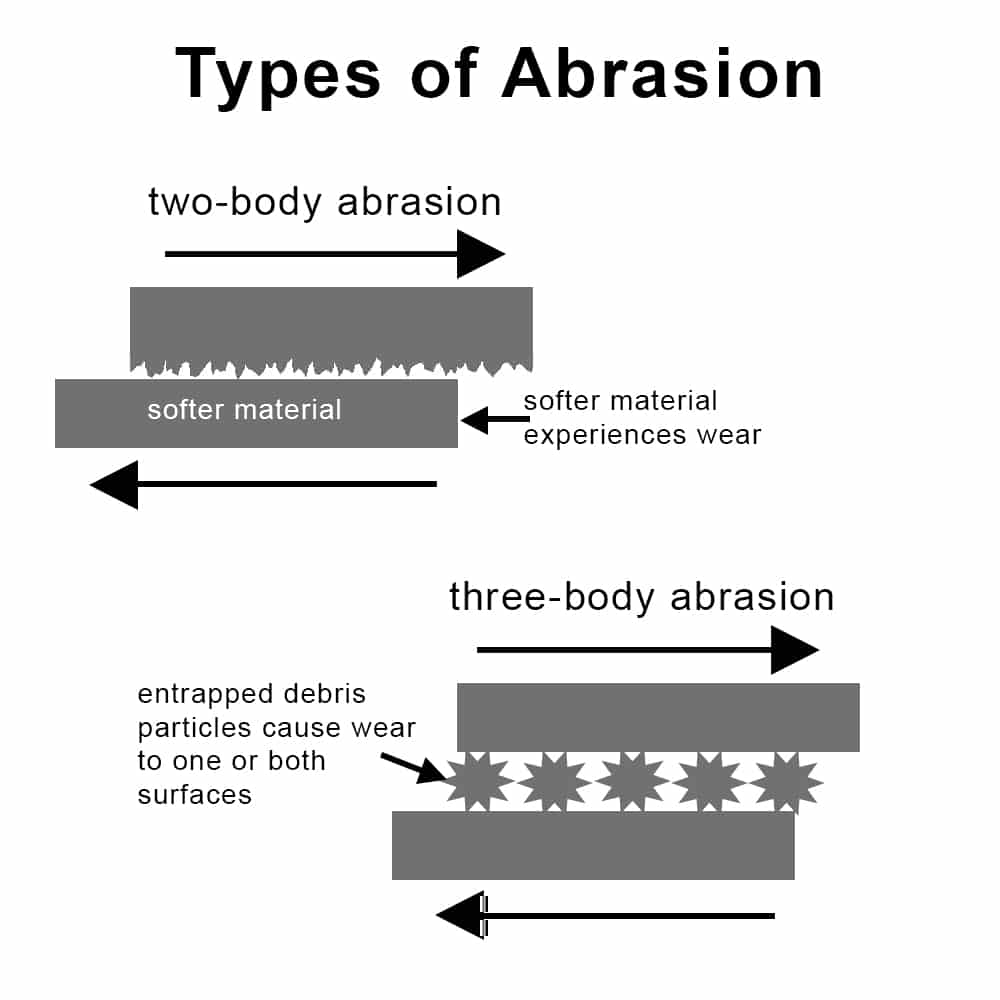

- Abrasive Wear: This type of wear occurs when hard particles or rough surfaces move across a softer material, leading to gradual material loss. It’s frequently encountered in dusty or particle-heavy environments, especially where filtration is limited.

- Adhesive Wear: When two metal surfaces slide against each other under pressure, microscopic welding and subsequent tearing can occur, resulting in material transfer. This mechanism can cause galling, seizing, and surface scoring.

- Corrosive Wear: A combination of chemical attack and mechanical motion, corrosive wear happens when a material is weakened by chemical exposure — such as acids, alkalis, or moisture — making it more susceptible to surface removal during operation.

- Fatigue Wear: Unlike the others, fatigue wear results from repeated cyclic loading that initiates microcracks and eventually leads to surface material flaking or pitting. It’s commonly seen in rotating parts like bearings, gears, and shafts under dynamic stress conditions.

Each type of wear may require a different surface engineering approach — whether through coating selection, material change, or process optimization — to reduce downtime and extend component life.