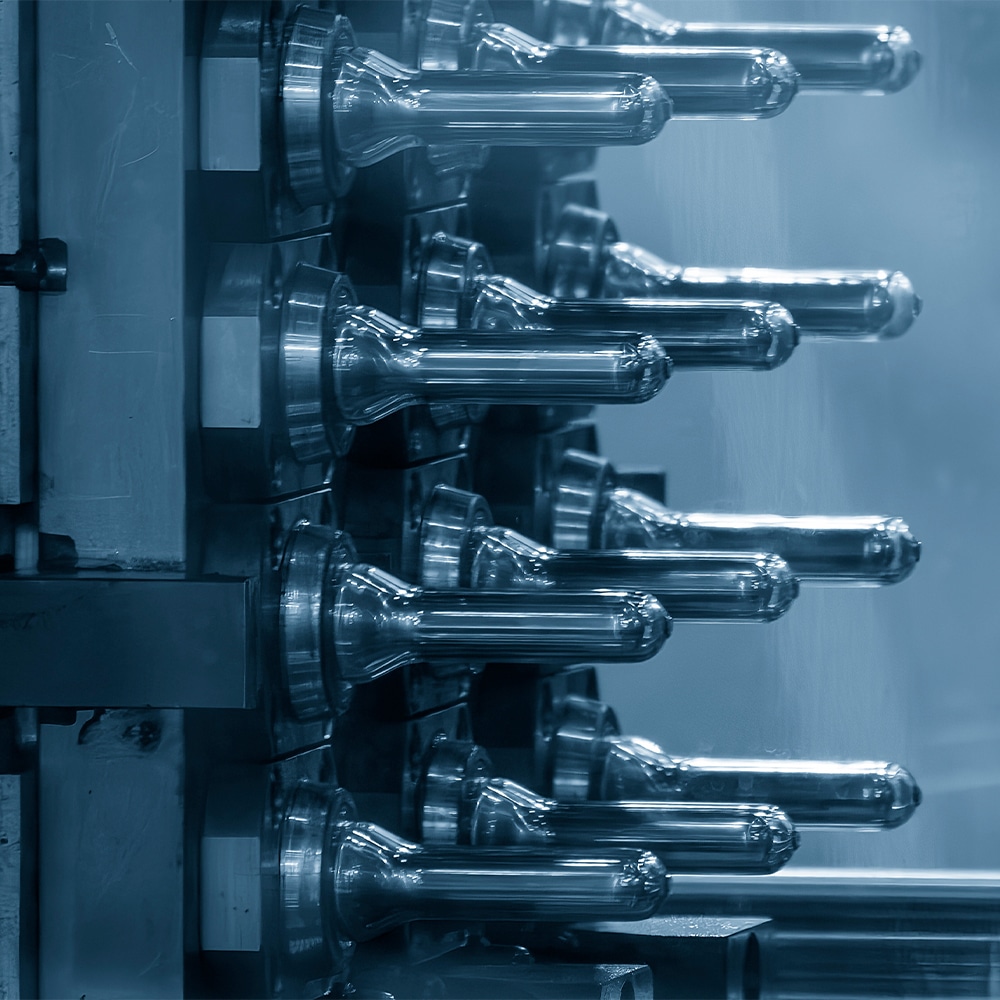

WHAT IS INJECTION BLOW MOLDING

Did You Know?

Injection Blow Molding (IBM) makes hollow plastic parts by injection‑molding a hot preform on a core rod, then blowing it into a cooled mold after indexing, which yields fully finished parts without flash. Typical uses include pharmaceutical and cosmetic bottles with precise neck finishes.

At-A-Glance Facts:

-

Also called:

triple-station IBM

- Typical where: small to medium bottles and jars in pharma/cosmetics and personal care

- Key inputs/components: injection mold, core rods, indexing turret (typically 3 stations), blow mold, take-out

- Quality risks to watch: thread/neck finish scuff from sliding on tooling; part-to-part wall balance depends on core-rod temperature and transfer timing

-

Common materials:

PP,

PE,

PETG,

PVC (application-dependent)

How It Works

A preform (parison) is injection‑molded onto a core rod. The turret indexes the core rod to a blow station, where compressed air enters through the rod and expands the hot preform against the blow mold.

The part cools in the mold and is stripped/ejected at the next station. IBM typically produces no flash because the neck finish is fully formed during injection.

Common Metal/Tooling Challenges in IBM

- Neck rings & thread splits: sliding contact → galling/scuffing and wear

- Core rods (blow pins): surface wear and sticking if finish is too “grippy”; occasional corrosion depending on resin/additives

- Blow molds: localized wear on parting features; heat‑checking where cooling is non‑uniform

- Plasticating unit (if integrated): abrasive/corrosive wear on screws/barrels when processing filled or PCR materials

Surface Engineering Options

Siloed by what you’re seeing on the tool (symptoms) so you can choose the right surface solution.

Start with the question: did the metal fail, or is it failing?

In injection blow molding, symptoms like scuffing on neck rings, sticking on core rods, hot spots near parting/neck features, or corrosion marks are the bridge between performance issues and root cause.

- Galling / scuffing on sliding interfaces

- Edge wear / geometry loss on critical features

- Corrosion / pitting (material- and chemistry-dependent)

- Hydrogen embrittlement risk (after electroplating on susceptible steels)

Performance failures we target

- Sticking / adhesion / buildup that disrupts cycle consistency

- Thread/neck finish scuff and cosmetic defects

- Frequent cleaning and maintenance interruptions

- Heat-related issues (hot spots, seam/parting integrity)

Important: “Armoloy-available treatments” are what we provide. “Other industry options” are common alternatives that may be supplied by other providers.

| What you’re seeing (symptoms) | Likely failure mode | Armoloy-available treatments | Other industry options (not offered by Armoloy) | Benefit focus |

| Scuffing on neck rings, thread splits, wear marks on sliding zones; parts show surface scuffs tied to tooling contact | Adhesive wear (galling) + sliding wear under load; friction-driven damage on contact interfaces |

Thin Dense Chrome (TDC) Thin, uniform hard surface to help mitigate wear and preserve critical geometry where tight tolerances matter. Surface engineering consult |

DLC (PVD/PACVD) (typical 1–5 µm) CrN (PVD) (typical 2–4 µm) Often selected for low friction and anti-galling behavior; supplied by PVD providers. |

Metal + performance Less galling/scuff, steadier quality |

| Sticking on core rods/blow pins; material pickup; higher ejection force; occasional corrosion marks depending on resin/additives | Friction + adhesion (buildup) and/or corrosion-driven surface roughness that increases “grip” |

High-Phos Electroless Nickel (ENP) (where specified) Uniform barrier coverage where corrosion resistance and thickness control are priorities. Electroless Nickel + PTFE (EN-PTFE) (where specified) |

DLC topcoat on select zones Sometimes used as a low-friction top layer; supplied by other providers. |

Performance failures Sticking, downtime, scrap reduction |

| Edge wear on critical features; loss of sharp definition leading to inconsistent neck finish, sealing issues, or cosmetic defects | Abrasive wear and geometry loss on sharp or high-contact features |

Thin Dense Chrome (TDC) Thin, uniform hard chromium to preserve sharp geometry with minimal dimensional growth. |

CrN (PVD) and other hard PVD films Often used when an external provider is selected for thin-film wear protection. |

Metal failures Wear mitigation / geometry retention |

| Hot spots, seam/parting integrity issues, temperature-driven dimensional instability near neck/parting features | Thermal management limitation (heat extraction and stability) more than a pure “coating problem” |

Surface engineering consult We help confirm whether a surface treatment is compatible with thermal goals and which areas should remain untreated for heat transfer. |

High-conductivity copper alloys (e.g., MoldMAX HH; AMPCOLOY 944) Common substrate/insert option to improve heat extraction in hot zones (material selection). |

Performance failures Quality stability / seam integrity |

| Corrosion risk, staining, haze after cleaning/washdown; surfaces that trap buildup or contaminate product | Corrosion initiation + surface roughness/buildup sites |

Electropolish + passivation (where applicable) Surface smoothing and corrosion-resistance restoration on suitable alloys to reduce buildup sites and improve cleanliness. |

ASTM A967 passivation (industry standard process) Commonly specified for stainless corrosion performance improvements (performed by qualified providers). |

Metal + performance Corrosion control & cleanliness |

| Concern about high-strength steels after electroplating; cracking risk under load after plating | Hydrogen embrittlement susceptibility (process risk that must be managed) |

Relief bake (post-plate) (when required by material/process) Used to reduce embrittlement risk on susceptible high-strength steels following electroplating. |

ASTM B850 guidance (industry standard) Common reference for post-plating embrittlement relief practices. |

Metal failures Risk mitigation |

How to use this section: Tell us the symptom, where it shows up (neck rings, core rods/blow pins, parting features), the resin/fill, and your dimensional constraints. We’ll validate the best Armoloy-available treatment—or point you to a proven industry alternative when that’s the better engineering call.

Have a Molding Issue? Let’s Chat

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.