- Armoloy of Ohio has specialized in Thin Dense Chrome for more than 40 years, serving industries that depend on precision above all else.

- Under the leadership of Chris Neely, Vice President of Sales, the team combines craftsmanship with collaboration across Armoloy’s Licensed Network of Fulfillment Centers worldwide.

- Through shared processes, science, and quality systems, the facility continues to deliver fast turnaround times, consistent results, and trusted partnerships that strengthen Armoloy’s global reputation for surface performance.

In Ohio’s industrial corridor just west of Columbus, Armoloy of Ohio has built its reputation on mastering one discipline: Thin Dense Chrome. For decades, its coatings have protected components in food production lines, automotive assemblies, linear motion systems, and aerospace equipment — industries that depend on accuracy above all else.

To understand what drives that consistency, we sat down with Chris Neely, Vice President of Sales, whose team in Ohio plays a vital role within the broader Armoloy network. His facility represents the legacy and the future of the brand: decades of hands-on expertise paired with a renewed spirit of collaboration across Armoloy Fulfillment Centers worldwide.

Through shared science, continuous improvement, and a collective commitment to quality, Armoloy of Ohio reflects a larger vision — where every facility works together to strengthen the surfaces that move the world forward.

Masters of Thin Dense Chrome

Few coatings have earned a reputation as enduring as Thin Dense Chrome, and for Armoloy of Ohio, it’s the foundation of everything they do. “Thin Dense Chrome is our specialty,” says Neely. “It’s the coating we’ve built our name on, and we’ve been perfecting it for years.”

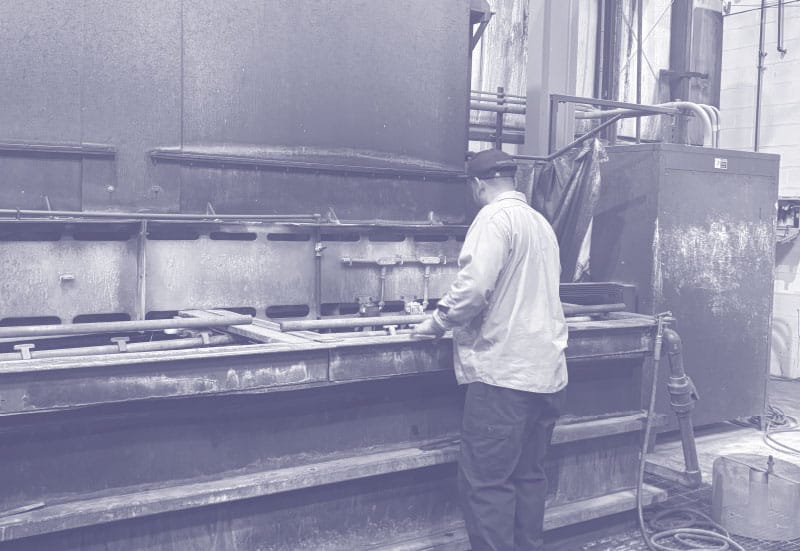

The team’s experience spans nearly every part geometry and size, from intricate dies to multi-ton turbine rolls. With three plating tanks — including one large enough for oversized components — and two five-ton bridge cranes running overhead, the facility is equipped for both finesse and heavy-duty applications. That capability supports industries where performance margins are tight and tolerances are non-negotiable.

Food processing remains one of their core strengths. Armoloy of Ohio has spent years coating pizza dies, tooling, and other components for frozen food production lines, developing an intuitive understanding of what each part demands. “We know what can be oiled, what needs a food-safe finish, and where the tolerances are tightest,” Neely explains. “That rhythm comes from years of repetition and relationships.”

Precision — in both measurement and method — defines the facility’s culture. Every technician knows the subtleties of their tanks, how current flows across a complex part, and what a perfect finish should look like. It’s a craft learned through experience, passed down from one generation of platers to the next, and carried forward with every part that leaves the shop floor.

Growth Through Collaboration

As precise as their work is, Armoloy of Ohio knows progress doesn’t happen in isolation. Collaboration across facilities has become essential to refining their craft and raising their standards.

Neely’s team recently completed Armoloy’s Tooling & Die Certification, a program designed to strengthen and align best practices for racking, current control, and setup across the entire network. The certification gave the Ohio team a chance to benchmark their methods against Armoloy’s standardized process playbook, validate what was already working well, and identify a few targeted refinements to elevate their operation even further.

One of those adjustments involved switching from copper racks to aluminum in key areas — a change that made day-to-day work safer and more efficient. “Aluminum is lighter and easier for the team to handle,” Neely explains. “That makes a real difference when you’re lifting racks in and out of tanks all day.” His crew also began building racks in-house that match vendor quality but can be fabricated in a week, rather than waiting months for shipment.

The certification reinforced another lesson that’s second nature in Ohio: quality starts before a part ever enters the tank. “Getting the setup right — the materials, the current flow, every contact point — leads to a cleaner, more precise deposit,” says Neely. “When you put that effort in upfront, the results speak for themselves.”

Those insights have paid off beyond the plating line. Working with other Fulfillment Centers and Armoloy’s corporate engineering team has helped standardize improvements across the network, especially in tank chemistry. Cleaner solutions, tighter controls, and shared maintenance methods allow the Ohio facility to maintain fast turnaround times without compromising finish quality.

What began as a certification exercise became a model for how collaboration drives progress within a unified system. For Neely and his team, each shared idea — from racking to chemistry — adds up to a smoother process, stronger results, and a better experience for every customer.

Fast Turnarounds and Trusted Partnerships

In manufacturing, downtime can halt entire production lines. Responsiveness matters as much as precision, and Armoloy of Ohio has built its reputation on both.

“Our turnaround time really sets us apart,” says Neely. “We pride ourselves on getting jobs done in three to five days — even five to seven is considered long for us.” Two shifts keep the tanks running from early morning to late evening, ensuring that critical parts move quickly through the line without sacrificing quality.

That speed comes from discipline — clean chemistry, tight process control, and crews who plan every step before the part hits the line. “We’ve got two solid crews who know how to keep things running,” Neely explains. “That’s what lets us respond fast when a customer calls with a line-down situation. In this business, every minute matters.”

For many customers, that reliability turns a vendor relationship into a partnership. Neely’s team manages jobs from quote to delivery, coordinating with other Armoloy facilities when parts require coatings beyond Thin Dense Chrome. “Customers don’t need to make four phone calls or juggle different vendors,” he says. “They call me, and I route it to the right place in the network.”

The network he refers to is Armoloy’s Licensed Network of Fulfillment Centers, which includes 15 locations worldwide: eight across North America and others throughout Europe, Asia, and South Africa. Each operates under the same processes, science, and quality systems, giving customers consistency wherever their parts are coated.

That collaboration defines the Armoloy approach: local expertise supported by the reach and technical depth of a global organization. For Neely’s customers, it means a seamless experience, clear communication, and confidence that every coating, no matter where it’s applied, meets the same high standard.

As Neely puts it, “Our customers trust that when they call us, the job’s going to get done right and on time. That trust is everything. It’s what keeps them coming back.”

The Culture Behind the Craft

Walk through Armoloy of Ohio’s shop floor and you’ll see the kind of familiarity that only comes with time. Many employees have spent more than a decade here — some more than two. “Our average tenure is around fifteen or sixteen years,” says Neely. “That kind of time builds trust. We know each other’s families, and our kids go to school together. You can argue on a Tuesday and be laughing about it on Wednesday.”

That trust extends to how work gets done. The shop runs on open communication and mutual respect — an environment where questions are encouraged and every voice carries weight. Experienced platers share what they know, while younger technicians bring new ideas and fresh ways of thinking. “It’s a good mix,” Neely says. “The younger guys push for new approaches, and the seasoned guys know what’s proven to work when time is tight. It keeps things balanced.”

Curiosity keeps the work meaningful. When technicians understand where a part is headed, they take personal pride in the result. “If we’re coating a mold that makes millions of name-brand trash bags, the team takes pride knowing their work keeps a familiar product running in homes across the country,” Neely explains. “If it’s a stamping die for a flagship American sports car, they give it the same attention, because they know it’s going into something special.”

That curiosity — wanting to know how each component will perform and who it’s for — keeps people engaged and accountable. It turns the routine of plating into a shared purpose: helping customers build products that perform better and last longer.

Stronger, Together

After 40 years in business, Armoloy of Ohio still approaches every project as a chance to improve. The team’s focus on clean chemistry, disciplined setup, and shared learning across the network keeps their process sharp and their results consistent. “We’re putting out the best product we possibly can, and we’re doing it more efficiently than we could a few years ago,” says Neely. “What used to take extra effort now runs like clockwork.”

Working closely with other Armoloy Fulfillment Centers has strengthened that momentum. Collaboration on process control, tank maintenance, and customer applications helps every facility move forward together — guided by the same processes, science, and quality systems.

For Neely, the reward comes down to trust. “Our customers know that when they send work our way, it’s going to be done right,” he says. “That’s what keeps us focused. That’s what keeps us proud to be part of Armoloy.”

Armoloy of Ohio continues to embody what makes the brand unique: precision rooted in craftsmanship, elevated by collaboration, and proven one surface at a time.

About The Armoloy Corporation

Headquartered in DeKalb, Illinois, Armoloy operates more than 15 licensed Fulfillment Centers worldwide. Since 1957, Armoloy has partnered with engineers, manufacturers, and innovators across every major industry to improve component performance, reduce friction and wear, and extend service life through advanced thin dense chrome and engineered coatings.

Today, every Armoloy Fulfillment Center operates under the same rigorous standards, training programs, and continuous-improvement systems — working together as one global network with one shared purpose: to strengthen the surfaces that move the world forward.