When using fully supported shafts/rails to control deflection on long spans. The slot clears the support; ensure proper under-support to avoid ovalizing.

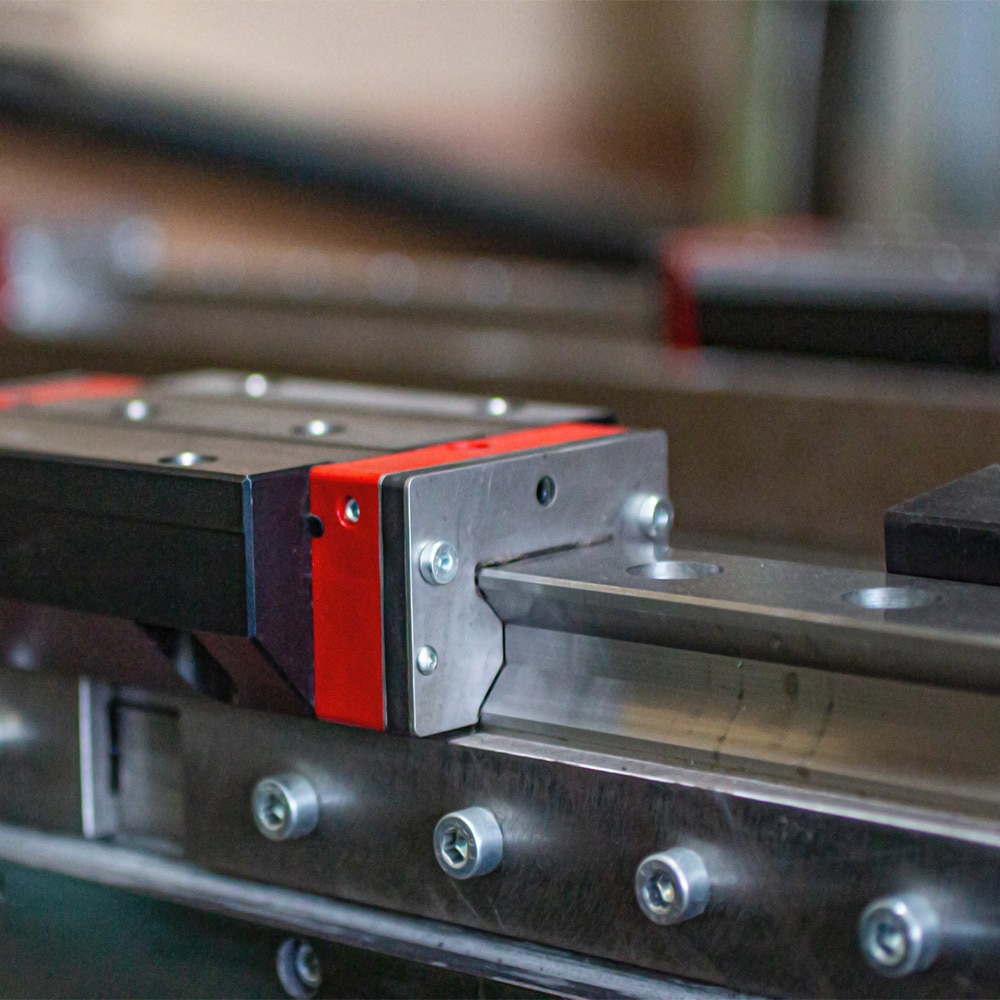

Linear Ball Bushing (Round Shaft)

A cylindrical sleeve with recirculating balls that ride on a hardened round shaft.

Offers low friction, modular mounting (open/closed, pillow blocks), and economical long-stroke motion.

Typical uses: packaging/automation axes, pick-and-place, 3D printing gantries, lab equipment, light CNC fixtures, adjustable slides.

Selecting Your Linear Ball Bushing System

Choose bushing style, housing, and shaft strategy to balance stiffness, contamination control, and cost.

| Choice | Use when | Watch-outs | Notes |

|---|---|---|---|

| Closed vs. Open bushing | Closed for standard shafts; open when using fully supported rails. | Open bushings need proper support under the slot to prevent ovalizing. | Open enables long spans with supported shafts; good for compact gantries. |

| Single vs. Double-length | Double length for higher load and moment capacity per bushing. | Longer units increase friction and envelope; maintain shaft straightness. | Two singles spaced apart can outperform one long in pitch/yaw. |

| Housing: Rigid vs. Self-aligning | Self-aligning pillow blocks tolerate small angular errors. | Rigid housings demand better parallelism—binding risk if misaligned. | Use one fixed datum housing + one floating to absorb growth. |

| Shaft support: End-supported vs. Fully supported | Fully supported for long spans/heavier loads; end-supported for short/light axes. | End-supported shafts deflect → binding/uneven feel; check sag/critical speed. | Use larger diameter or supported rail to control deflection. |

| Shaft material/finish | Through-hardened or case-hardened precision shafting; polished low-Ra surface. | Soft or rough shafts groove quickly; noise and backlash rise. | Stainless/coated shafts where corrosion or washdown exist. |

| Seals & wipers | Add in dust/spray; consider shaft covers near process areas. | More contact raises drag—verify motor sizing for long strokes. | Purge after washdown to refresh film and flush debris. |

Mounting & Design Rules (Quick)

-

Align shafts as a pair: One shaft “master”, the other shimmed/floating; torque-map travel to find tight spots.

-

Straightness & support: Control deflection with supported rails or larger diameters on long spans.

-

Surface matters: Hardened, polished shafts (low Ra) extend life and keep motion smooth.

-

After coating: Re-measure shaft size/roundness; re-check bushing clearance and seal contact.

Environment → Recommended Attributes (Ball Bushings)

| Environment | Bushing/Housing | Shafting | Sealing/Covers | Lube |

|---|---|---|---|---|

| Dusty / light chips | Closed bushings in pillow blocks; self-aligning if base is rough. | Hardened, polished carbon steel shafts. | End wipers + simple covers/deflectors. | Grease with regular purge. |

| Washdown / corrosive | Stainless/coated bushings; self-aligning housings preferred. | Stainless or coated shafts; protect against jets at seals. | Wipers + shaft covers; avoid directing jets at wipers. | NSF H1 grease; purge + drying routine. |

| Long span / heavier load | Double-length or two spaced bushings per station. | Fully supported shafts or larger diameters. | Covers to keep debris off support extrusions. | Grease or light oil; verify heat rise. |

| Cleanroom / lab | Low-noise cages; precise housings. | Polished shafts with very low Ra. | Minimal-contact wipers; clean covers. | Low-bleed grease or metered light oil. |

Common Failures & Diagnostics

1) Shaft Grooving / False Brinelling

Symptoms

Rough feel, audible clicking, lines or dimples along the stroke path.

Likely causes

Soft/rough shafting, contamination, vibration at rest with marginal film.

Checks

Shaft hardness/finish, wiper condition, grease condition, parked position habits.

Non-coating actions

Upgrade shaft (hardened/polished), improve wipers/covers, increase purge cadence, move park point.

When surface treatments help

Hard, low-Ra chromium-family surfaces on shafts resist fretting initiation.

2) Binding / Stick-Slip Mid-Stroke

Symptoms

Variable torque, jerky motion, noise near certain positions.

Likely causes

Shafts not parallel or sagging; rigid housings with misalignment; open bushings without support.

Checks

Parallelism with indicators; shaft deflection model; housing squareness.

Non-coating actions

Add support rail or larger diameter; switch one housing to self-aligning; re-shim “slave” side.

When surface treatments help

Not primary—mechanics first; coatings only for corrosion/wear margin.

3) Corrosion / Staining After Washdown

Symptoms

Brown staining near wipers, noisy restart, early seal wear.

Likely causes

Aggressive cleaners, poor drying, incompatible grease.

Non-coating actions

Change wash angles, protect wipers from direct jets, use validated H1 grease, add drying routine.

When surface treatments help

Thin dense chrome on shafts slows rust initiation and eases cleanup.

Corrosion, Lubricity, Dimensional Stability

| Concern | Controls (non-coating first) | When coatings help | Notes |

|---|---|---|---|

| Corrosion | Wipers, shaft covers, wash/dry protocol, compatible grease. | Chromium-family thin dense on shafts (and housings if needed). | Re-check clearance after coating; verify seal contact. |

| Lubricity | Right viscosity; purge cadence; protect wipers from jets. | Low-Ra hard chrome reduces fretting/false brinelling. | Coatings complement lubrication—not a replacement. |

| Dimensional stability | Supported rails for long spans; one housing floating; re-shim after assembly. | Controlled-thickness coatings; verify post-coat fit & runout. | Open bushings need proper under-support to avoid ovalizing. |

Frequently Asked Questions

Two spaced bushings per shaft dramatically increase moment capacity and reduce racking. Adjust spacing to tune stiffness vs. envelope.

Yes—coating thickness on shafts changes running clearance and seal contact. Measure post-coat, then re-hone/adjust as needed.

Likely shaft straightness/finish variation or contamination at wipers. Torque-map the stroke and inspect/replace wipers; re-polish or replace shaft if grooved.

Partner With Us

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).