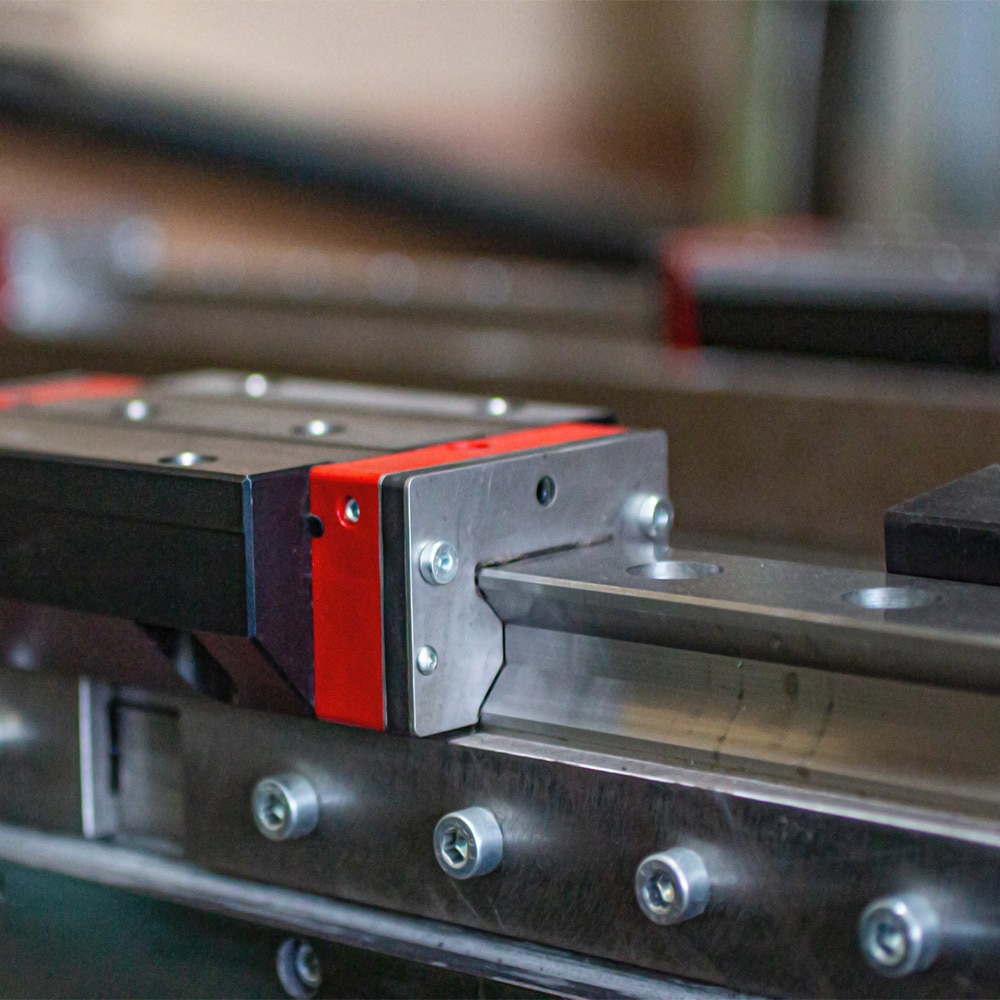

Two per rail dramatically increase pitch/yaw moment capacity and reduce rail stress. Use carriage spacing to tune stiffness vs. envelope.

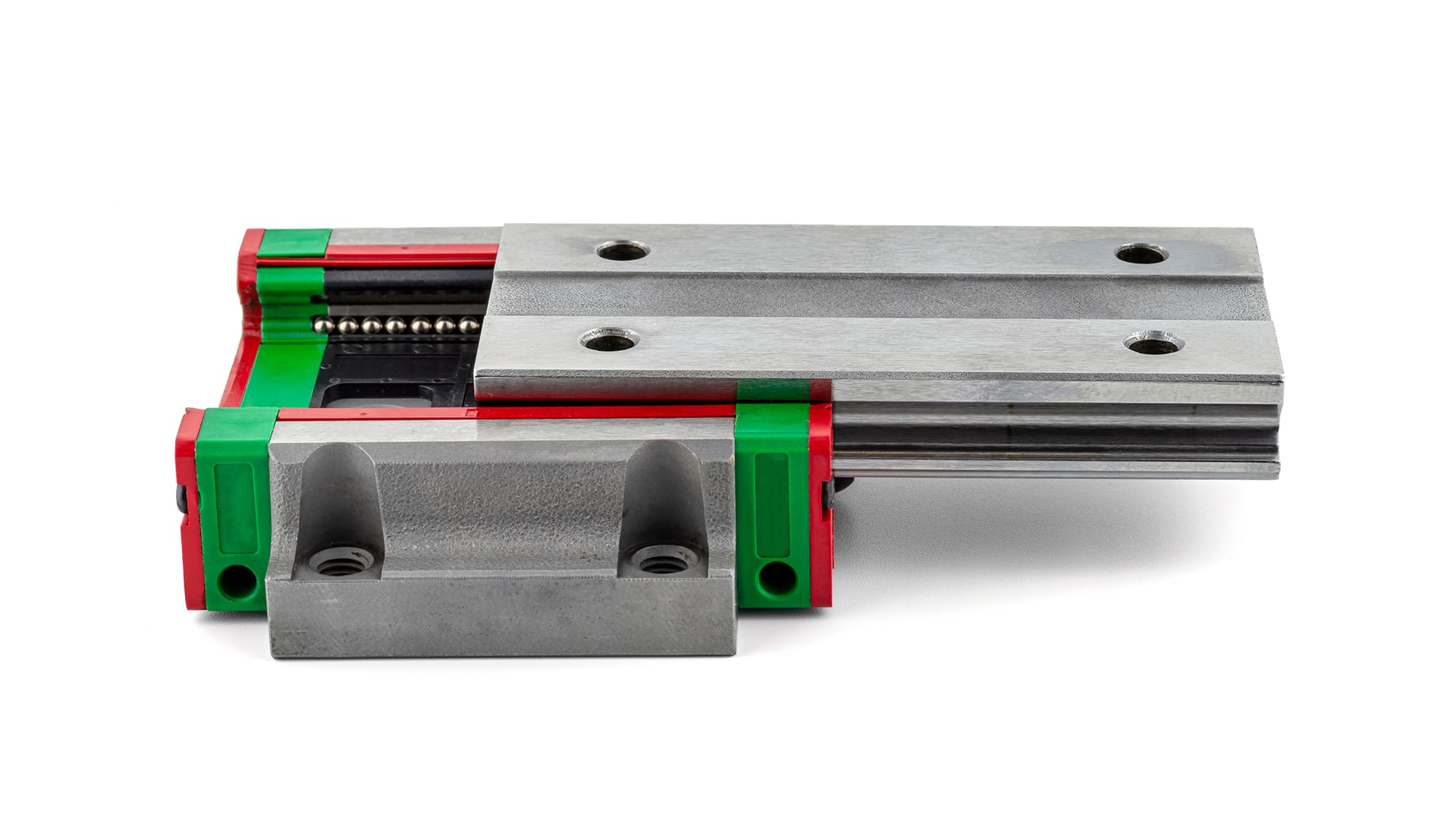

Profile Rail — Recirculating Ball Guides

Linear guideway with hardened steel rails and a ball-recirculating carriage. Provides smooth motion with four-direction load capacity, configurable preload, and compact form factor.

Typical uses: CNC/automation axes, pick-and-place, packaging lines, medical devices, lab automation, 3D printers (industrial), inspection stages.

Selecting Your Ball Profile Rail

Pick carriage form factor, preload, and sealing based on load, stiffness, contamination, and duty cycle.

| Choice | Use when | Watch-outs | Notes |

|---|---|---|---|

| Carriage length: Short / Std / Long | Long for higher moment stiffness; short for compact z-axes or low M loads. | Longer blocks add friction and cost; ensure straightness to avoid binding. | Two carriages per rail increase pitch/yaw capacity significantly. |

| Preload: Light / Medium / Heavy | Light for most automation; medium for machining/precision cuts. | Higher preload raises torque/heat; traps debris in dirty service. | Verify running torque post-assembly; avoid over-preloading stacked axes. |

| Sealing: End wipers / Scrapers / Bottom seals | Scrapers for chips/slurry; bottom seals for inverted/side-mount; double-lip for spray. | More seal contact = more drag; confirm motor sizing. | Add bellows/covers where chips or jetting overwhelm wipers. |

| Material/finish: Std / Stainless / Coated | Stainless/coated rails for washdown or corrosives. | Coating thickness can shift height; re-map after install. | Protective caps for screw holes help cleanliness and appearance. |

| Rail strategy: Fixed + Floating | Long travels; temperature swings; mixed materials. | Both rails fixed = binding as system heats. | Index “master” rail first; shim “slave” rail to torque map. |

Mounting & Design Rules (Quick)

-

Master → slave rail: Align one rail as the datum; torque-map carriage drag while shimming the second rail.

-

Parallelism & flatness: Verify with straightedge/laser; record torque vs. position to catch local errors.

-

Thermal growth: Use fixed+floating rails; avoid over-constraining long bases.

-

After coating: Re-measure rail height/straightness; re-check preload and seal contact.

Environment → Recommended Attributes (Profile Ball Rails)

| Environment | Rail/Carriage Options | Sealing/Covers | Lube | Notes |

|---|---|---|---|---|

| Washdown / Food | Stainless or coated rails; corrosion-tolerant blocks | Double-lip wipers; deflectors; avoid direct jets at lips | NSF H1 grease; purge after wash; drying routine | Cap holes; manage water traps at ends |

| Chips / Abrasives | Hardened rails; long blocks for moment loads | Metal scrapers; full covers/bellows; vacuum extraction | Tacky greases; scheduled purge | Keep recirculation grooves shielded |

| Cleanroom / Metrology | High accuracy class; low-outgassing grease | Non-contact shields/clean covers | Light oil metering or low-bleed grease | Cable routing to minimize force ripple |

| High Speed / Long Stroke | Light preload; standard blocks to reduce drag | Low-drag seals; continuous covers | Oil metering preferred; check heat rise | Fixed+floating rails; expansion joints |

Common Failures & Diagnostics

1) Contamination → Brinelling / Rough Runs

Symptoms

Clicking at repeat positions, rising drag, vibration bands in machined finish.

Likely causes

Weak wipers, no covers; chips packing at end caps; magnetized fines.

Checks

End-seal integrity; debris behind scrapers; grease condition; torque map vs. position.

Non-coating actions

Upgrade to scrapers + bellows; add vacuum or deflectors; set purge cadence.

When surface treatments help

Hard, low-Ra coatings on rails improve fretting and corrosion resistance.

2) Corrosion After Downtime

Symptoms

Brown staining at ends/seal lips; noisy restart after wash.

Likely causes

Aggressive cleaners, poor drying, incompatible grease.

Non-coating actions

Change wash angles; H1 grease validated vs. chemistry; drying routine.

When surface treatments help

Thin dense/micro-cracked chrome reduces rust initiation on rails.

3) Binding Mid-Stroke / Hot Carriage

Symptoms

Axis stalls, burnt grease odor, torque spikes near joints.

Likely causes

Rails not parallel/flat; both rails fixed; carriage stack misaligned.

Checks

Dial/lazer straightness; temperature scan; joint step at rail butt.

Non-coating actions

Re-shim slave rail; set fixed+floating; reduce preload; re-index joints.

When surface treatments help

Not primary—correct mechanics first; coatings only for corrosion control.

Corrosion, Lubricity, Dimensional Stability

| Concern | Non-coating controls first | When coatings help | Notes |

|---|---|---|---|

| Corrosion | Seals/wipers + covers; wash protocol; drying; hole caps | Chromium-family thin dense coatings on rails/shafts | Validate vs. cleaner chemistry; re-map height after coat |

| Lubricity | Right viscosity; purge interval; avoid over-preload | Micro-textured hard chrome reduces fretting/false brinelling | Coatings complement lubrication—not a substitute |

| Dimensional stability | Flatness/parallelism; fixed+floating; joint relief | Controlled-thickness coatings; verify post-coat straightness | Long rails & thin sections are sensitivity hotspots |

Frequently Asked Questions

Start light. Go medium if deflection degrades cut quality/accuracy. Heavy only on clean, well-sealed systems with ample motor torque.

Coating thickness can alter rail height/straightness at the micron level. Always re-map after coating and adjust shim/preload.

Thermal growth and base expansion can over-constrain rails and cause binding. Fix one rail, let the other float to absorb growth.

Partner With Us

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).