High load at low speed, oscillation, contamination tolerance, simplicity, or quiet operation—especially when PV and heat are manageable.

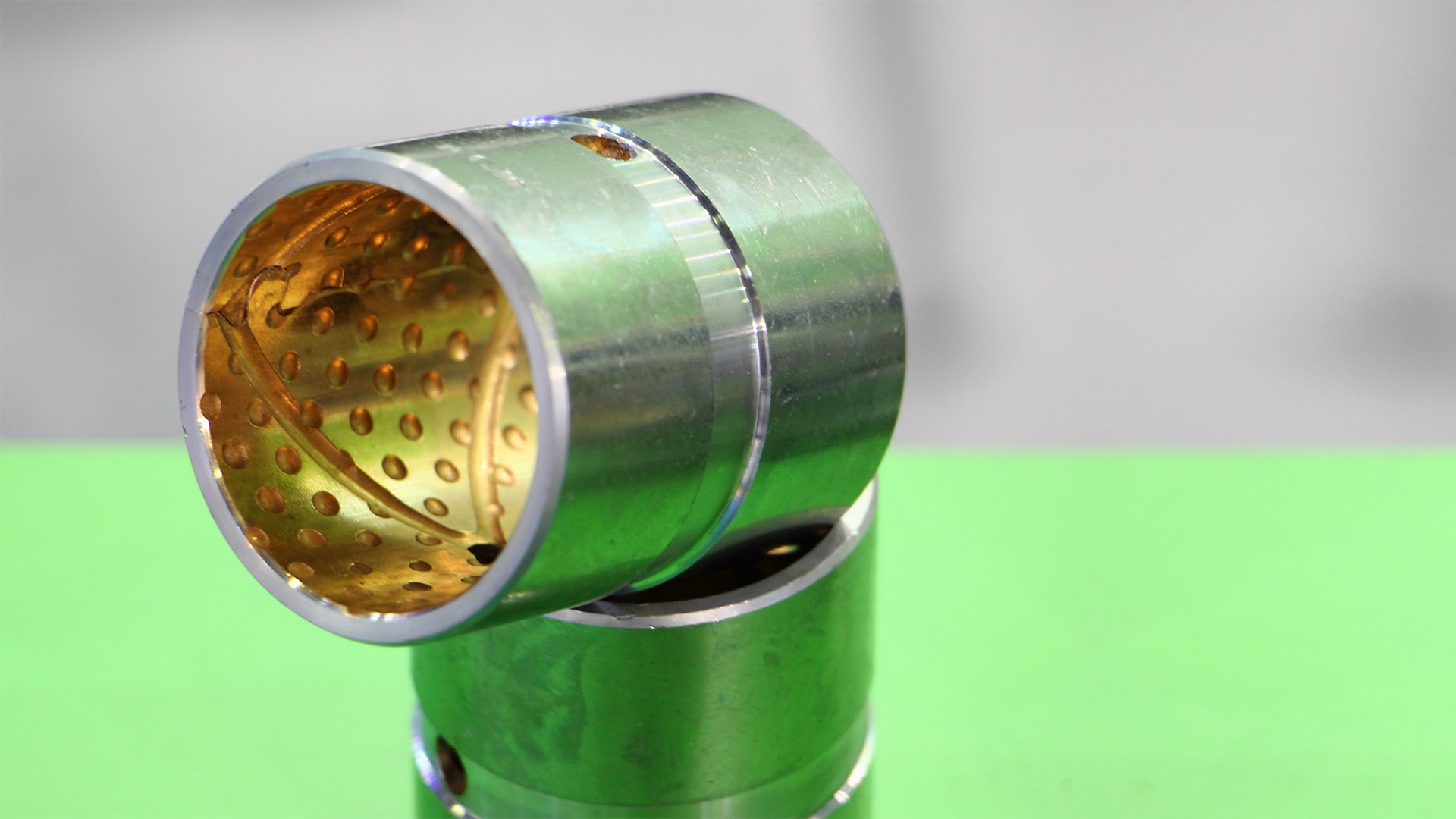

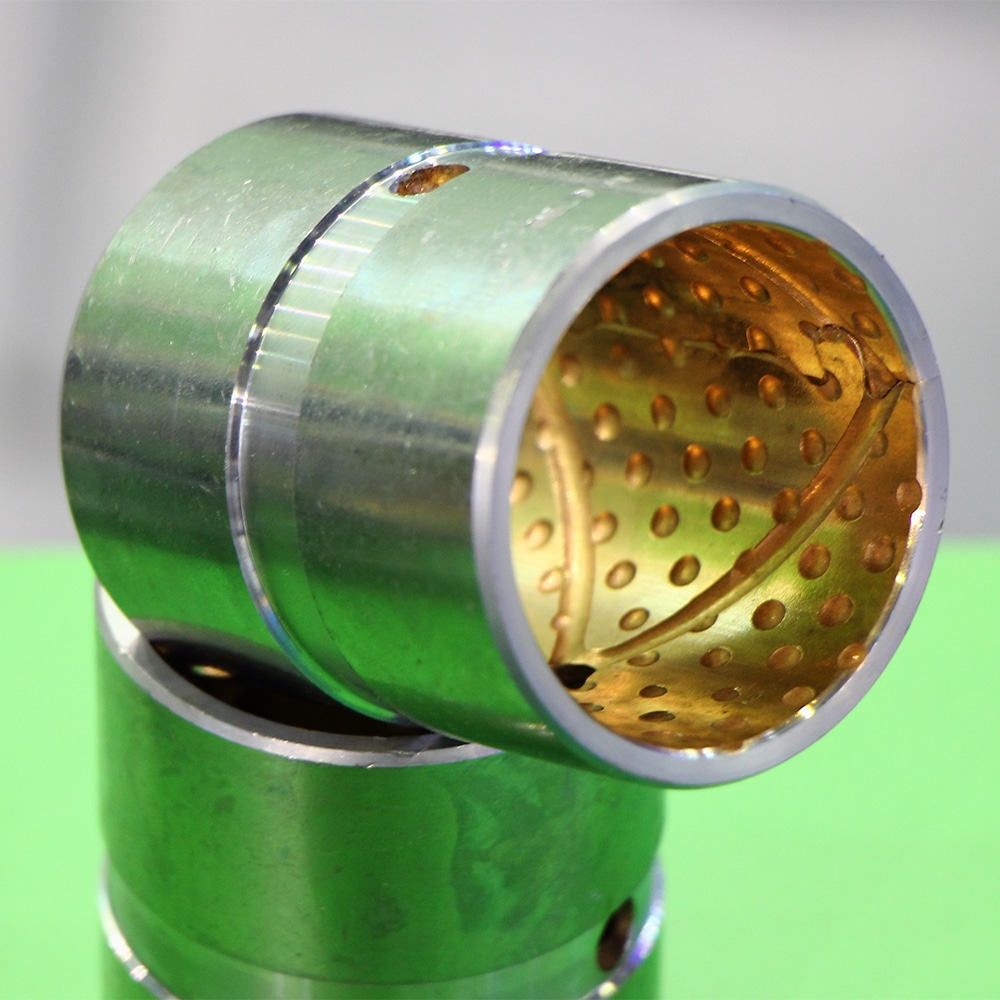

What Is a Plain Bushing (Sleeve/Journal Bushing)?

A plain bushing is a cylindrical sleeve that supports a rotating or oscillating shaft. Load is carried over area (no rolling elements). Performance depends on materials (bronze, metal-polymer PTFE, polymers, composites, babbitt), lubrication regime (boundary, mixed, hydrodynamic), and clearance/finish.

Typical uses: oscillating linkages, conveyor rollers, packaging machinery, pumps/fans (sleeve ends), industrial hinges, AG/food equipment, high-load low-speed shafts.

Selection Cheatsheet (Duty, PV, Environment, Lubrication)

- Duty cycle: continuous rotation → size for hydrodynamic film; oscillation/start-stop → prioritize boundary performance (PTFE/composite).

- PV rating: check material P×V limits; reduce load or speed if heat can’t be removed.

- Environment: water/chemicals → stainless + inert surfaces; dust → seals/deflectors + wear-tolerant surfaces.

- Geometry: L/D ≈ 0.5–1.0 typical; shorter aids misalignment tolerance; chamfered edges prevent scraping.

- Surface finishes: shaft Ra typically ≤ 0.2–0.4 μm for polymer/PTFE; harder/ground for bronze/babbitt.

- Post-process: coating/lining changes ID—hone/ream to final size; re-check clearance hot.

Environment → Attributes Matrix

| Environment | Material / Surface | Clearance & Bushing Finish | Fits (shaft / housing) | Sealing | Lubrication |

|---|---|---|---|---|---|

| Oscillating pivots / low speed | Metal-polymer PTFE or fiber composite; chrome-finished shaft for low adhesion | Nominal clearance; shaft Ra ≤ ~0.2–0.4 μm | k5–m6 / H7 (rotating shaft) | Guards/deflectors; optional contact seals | Grease or dry-run rated liners (per catalog PV) |

| Continuous rotation (oil bath) | Bronze/babbitt; controlled grooves | Clearance sized for hydrodynamic lift @ temp | Interference on housing; shaft to spec for runout | Non-contact seals/labyrinths | Oil (viscosity @ temp); de-aeration & filtration |

| Washdown / Food | Stainless shells; inert chrome or Ni-P on shafts; polymer liners validated for H1 | C3-like looseness concept if thermal growth expected | k5–m6 / H7; verify post-coat ID | Contact seals + deflectors; avoid jets at lips | H1 grease; purge after wash; dry-out routine |

| Dusty / Abrasive | Hard, low-roughness shaft coatings; wear-tolerant liners | Keep film; don’t over-tighten clearance | Secure fits to prevent creep/fretting | Labyrinth + shields; purge paths | Grease with sealing behavior; set purge interval |

| High temperature | High-temp polymers/comp., bronze/babbitt with oil; validate coating stability | Clearance for thermal expansion; re-check hot | Thermal growth model for fits | Heat shields / non-contact seals | High VI oil or dry-film compatible liner |

Common Failures & Diagnostics

Rapid Triage

1) Seizure / Scoring (loss of film)

Symptoms

Squeal, rapid temp rise, visible scoring/transfer on shaft/bore.

Likely causes

Under-lubrication, viscosity too low at temp, clearance too tight, misalignment.

Checks

Viscosity at operating temp; oil/grease supply; clearance hot; alignment/roundness.

Non-coating actions

Increase viscosity/supply; adjust clearance; fix alignment; add grooves.

When surface treatments help

Low-roughness/micro-textured chrome reduces adhesion after film is reliable.

2) Wear / Ovalization (boundary duty)

Symptoms

Increasing play, oval bore, black/grey wear debris.

Likely causes

High PV without cooling, abrasive ingress, soft shaft, poor finish.

Checks

PV vs. catalog; particle control; bushing hardness/finish; sealing.

Non-coating actions

Switch to PTFE/composite liner; harden bushing; improve sealing/filtration.

When surface treatments help

Hard chrome on bushing resists abrasion and adhesive wear.

3) Fretting / False Brinelling at Seats

Symptoms

Reddish oxide at OD/ID fits, micro-movement marks, squeak.

Likely causes

Insufficient interference, vibration in idle, thermal cycling.

Checks

Fit class vs. duty; transport profile; clamp integrity.

Non-coating actions

Increase interference or add retention features; stabilize transport.

When surface treatments help

Micro-textured chrome on seats lowers adhesion once fits are correct.

4) Stick-Slip / Squeal

Symptoms

Jerky motion at start; audible squeal; torque ripple.

Likely causes

Boundary regime with high static/kinetic friction ratio; incompatible grease; rough bushing.

Checks

Grease chemistry; bushing finish; load vs. speed; temperature.

Non-coating actions

Change grease/viscosity; polish bushing; adjust load or speed profile.

When surface treatments help

Low-roughness chrome and PTFE-friendly surfaces reduce stick-slip.

5) Corrosion (washdown/chemicals)

Symptoms

Rust staining, pitting, binding after wash cycles.

Likely causes

Inadequate sealing/dry-out; aggressive cleaners; incompatible metals.

Checks

Cleaner pH/chlorides; seal lip condition; dry-out routine; material pairing.

Non-coating actions

Improve seals/deflectors; change wash angles; choose H1 grease; passivate.

When surface treatments help

Hard, inert chrome or Ni-P on shaft/bores delays corrosion initiation.

The Big Three: Corrosion, Lubricity, Dimensional Stability

Use coatings when they address surface-driven issues (corrosion, fretting, abrasion) on bushings, housings, thrust faces. Coatings don’t replace proper clearance, alignment, sealing, or lubricant choice.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Protect bushings/bores under water/chemicals | Seals/deflectors; washdown angles; drying | Thin dense / micro-cracked chrome, Ni-P (validated) | Re-measure ID/OD after processing |

| Lubricity | Reduce start/stop and oscillation friction | Correct viscosity; choose PTFE/composite liners for boundary duty | Low-roughness or micro-textured chrome; solid-lube-friendly surfaces | Coatings complement—not replace—lube strategy |

| Dimensional stability/wear | Keep clearance and roundness in spec | Thermal model; rigid seats; alignment | Controlled-thickness coatings; hone/ream to size | Thin walls are thickness-sensitive |

Fits, Geometry & Clearances (Quick Rules)

- Rotating shaft → interference at housing to prevent bush creep; keep shaft to running clearance spec.

- Clearance is king: size for temperature & film; verify hot clearance, not just cold.

- Edges & grooves: chamfer edges; use axial/spiral grooves only where they won’t starve the loaded zone.

- After coatings: Re-evaluate for affect on preload.

Frequently Asked Questions

Only if they don’t starve the loaded zone. For oscillation, grease pockets can help; for rotation, design grooves for flow and heat removal.

No. Coatings help with corrosion/fretting and friction, but you still need adequate hardness and finish for the duty.

As loose as needed to maintain film at temperature and avoid seizure—model hot conditions; verify after any processing.

Expect change. Ream or hone to final ID; re-check roundness and alignment before install.

Case Snapshots

- Packaging pivot squeal — Oscillating arm squeaked after washdowns.

Actions: swapped to PTFE-lined bush + hard chrome bushing; added deflectors and H1 grease purge after wash.

Outcome: quiet starts; reduced wear debris. - Conveyor sleeve seizure — Bronze bush ran hot at increased speed.

Actions: resized clearance for hot condition; moved to oil bath with de-aeration; polished bushing.

Outcome: stable temperature; no scoring on teardown.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).