Hydrostatic (externally pressurized). Aerostatic gas also supports contact-free start if supply is on.

What Is a Fluid Bearing?

A bearing that supports load on a pressurized fluid film—oil, water, or gas—so the surfaces do not touch in normal operation. Families include hydrodynamic (film generated by motion), hydrostatic (film from external pump), and gas/air bearings (aerodynamic or aerostatic). Benefits: very low friction, high speed, excellent precision, and no wear when film is maintained.

Typical uses: turbomachinery (compressors, blowers), spindles & metrology stages, high-speed motors, paper/steel process rolls, machine tool slides, medical/food equipment (water-lubricated), cleanroom/vacuum motion systems.

Selection Cheatsheet (Duty, Film Source, Environment, Controls)

- Zero-speed load? Choose hydrostatic (externally pressurized) so the film exists before motion.

- Highest speed & cleanliness? Choose gas (aerostatic for start/stop, aerodynamic/foil for compact high speed).

- General industrial speed/load with robustness? Choose hydrodynamic (journal/thrust, tilting-pad for stability).

- Environment drives materials: water/food → stainless + inert coatings; vacuum/cleanroom → low-outgassing surfaces.

- Controls before coatings: supply pressure/flow, viscosity @ temp, filtration, thermal management, alignment/flatness.

- After coatings: re-measure IDs/ODs/flatness/groove geometry; verify lift-off speed, stiffness, and leakage.

Fluid Bearing Types — Quick Comparison

| Type | How the film is made | Pros | Watch-outs | Typical uses |

|---|---|---|---|---|

| Hydrodynamic (journal/thrust, incl. tilting-pad) | Wedge film from relative motion & viscosity | Simple hardware, good damping, high speed capability | Start/stop rub; viscosity @ temp critical; stability/whirl at certain loads | Turbomachinery, large rolls, motors, gearboxes |

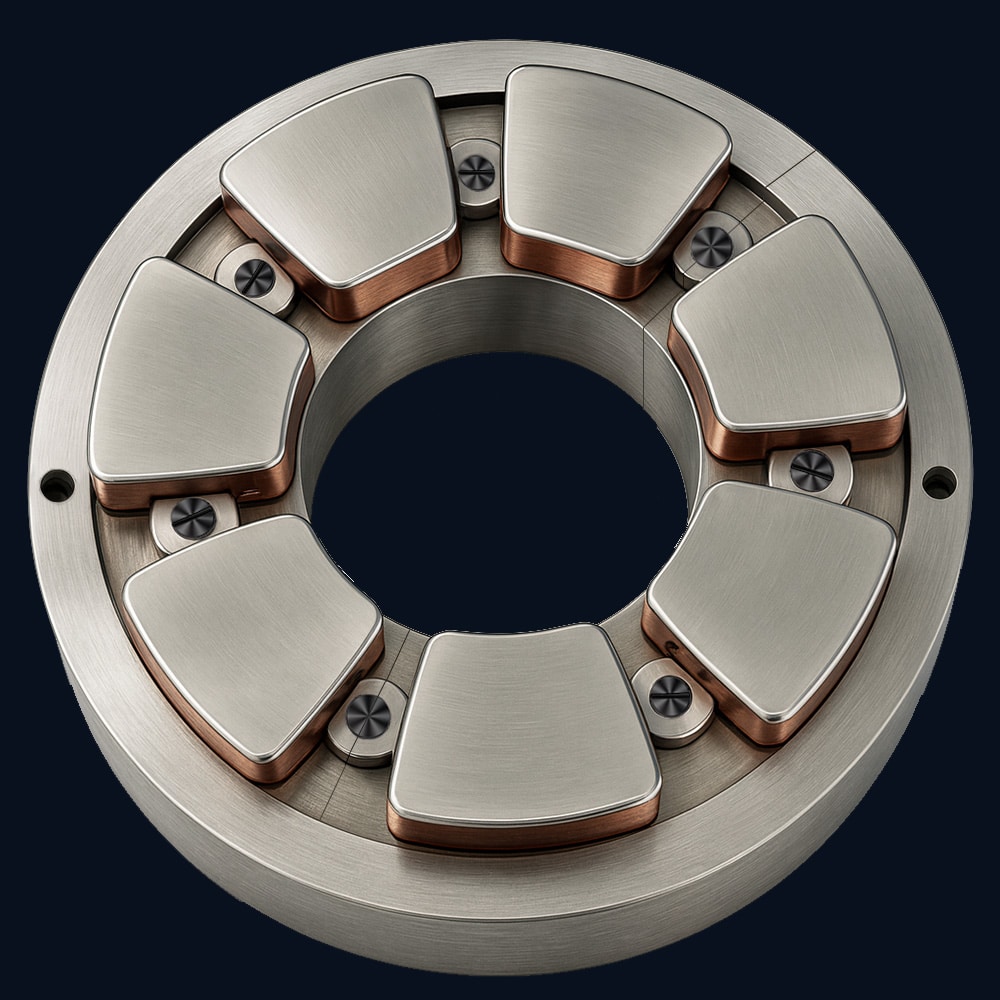

| Hydrostatic (externally pressurized) | Pump supplies pressure to recesses; film exists at zero speed | High stiffness/accuracy; excellent low-speed behavior | Pumps/controls, power & heat; contamination-sensitive | Precision spindles/tables, heavy machine tools, metrology |

| Gas (aerostatic) | External compressed air through orifices/porous media | Contact-free start; clean; ultra-low friction/torque | Lower damping; high air cleanliness need; stiffness depends on supply | Semiconductor/inspection stages, precision rotary tables |

| Gas (aerodynamic/foil) | Self-generated film at speed; compliant foils support start/stop | High speed; compact; no external supply needed | Start/stop rub on foils; heat; materials compatibility | Blowers, microturbines, high-speed fans |

| Water-lubricated | Hydrodynamic or hydrostatic with water as the fluid | Food/biocompatible; low environmental impact | Corrosion risk; low viscosity → lift & heat challenges | Pumps, food processing, marine shafts |

Common Failures & Diagnostics

Rapid Triage

1) Loss of Film / Rub (start/stop or starvation)

Symptoms

Temperature spikes, metal transfer, discoloration, rising torque.

Likely causes

Insufficient supply pressure/flow, low viscosity at temp, delayed pump start, purge air wet/oily.

Checks

Pressure/flow logs; viscosity vs. operating temp; lift-off speed; start sequence timing.

Non-coating actions

Raise supply pressure/flow; increase viscosity or cooling; interlock pump start before motion.

When surface treatments help

Low-roughness or solid-lube-friendly surfaces can reduce start damage but won’t fix low supply.

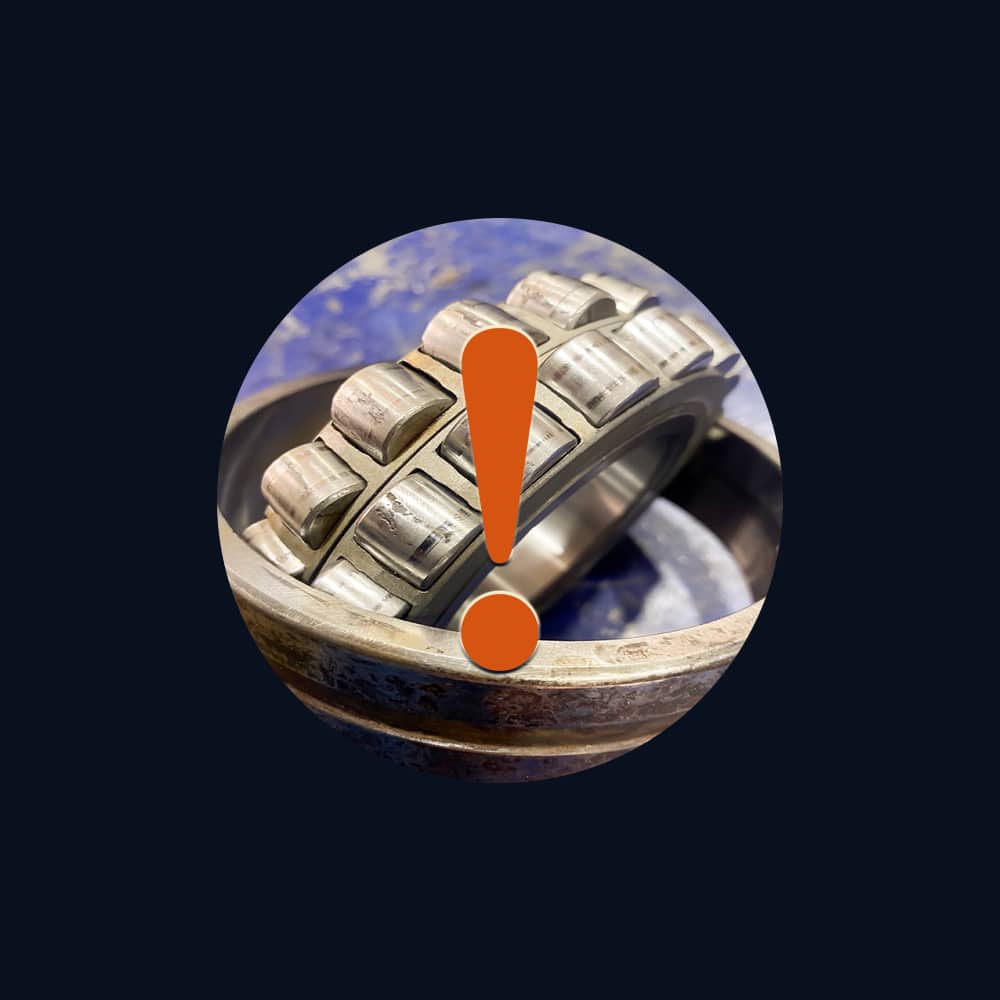

2) Contamination (particles, water, air entrainment)

Symptoms

Noise/torque ripple, pad/journal scoring, shortened life.

Likely causes

Poor filtration, seal failures, improper handling, aerated oil.

Checks

ISO cleanliness codes; filter ΔP; de-aeration efficacy; seal inspection.

Non-coating actions

Upgrade filters/strainers; improve seals; air removal; maintenance discipline.

When surface treatments help

Hard, inert chrome resists abrasion/corrosion once ingress is controlled.

3) Thermal Runaway / Viscosity Collapse

Symptoms

Escalating temperature, loss of stiffness, whirl/instability.

Likely causes

Too low viscosity at temp; inadequate cooling; excessive load/speed.

Checks

Oil temp control; viscosity index; heat balance; rotor balance.

Non-coating actions

Increase viscosity or reduce temperature; improve cooling/flow; verify alignment and balance.

When surface treatments help

Not primary—thermo-hydrodynamics first.

4) Gas Bearing Instability (subsynchronous whirl)

Symptoms

Vibration at sub-synchronous frequencies; position error on stages.

Likely causes

Low damping; high cross-coupled stiffness; supply pressure variation.

Checks

Spectrum analysis; supply pressure stability; stiffness modeling.

Non-coating actions

Add damping (squeeze film/tilting pads), tune orifices, increase preload, stabilize supply.

When surface treatments help

Secondary—stability is a system property.

5) Water Chemistry / Corrosion Attack

Symptoms

Rust staining, pitting, roughness growth, torque rise.

Likely causes

Chlorides/pH out of range; stagnant water; incompatible materials.

Checks

Water quality logs (pH, chlorides); flow; dry-out procedure after washdown.

Non-coating actions

Correct chemistry; ensure circulation/dry-out; upgrade seals/deflectors.

When surface treatments help

Hard, inert chrome or Ni-P improve corrosion resistance on journals/pads.

The Big Three: Corrosion, Lubricity, Dimensional Stability

Apply coatings when they address surface-driven mechanisms (corrosion, fretting, abrasion) on journals, thrust pads, or housings. Coatings don’t replace supply pressure/flow, viscosity control, filtration, or alignment.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Protect journals/pads & housings from water/chemicals | Seal strategy; chemistry control; de-aeration/drying | Thin dense/micro-cracked chrome or Ni-P (validated) | Check food/biocompatibility; re-measure geometry |

| Lubricity | Stable film, low start/stop friction (hydro + gas) | Viscosity @ temp; supply pressure/flow; filtration | Low-roughness or micro-textured chrome; solid-lubricant topcoats for foil starts | Coatings complement—not replace—fluid film formation |

| Dimensional stability | Hold clearances, flatness, and groove geometry | Thermal control; alignment; controlled assembly torque | Controlled-thickness coatings; post-coat metrology | Tiny thickness shifts change lift-off, stiffness, leakage |

Mounting, Supply & Geometry (Quick Rules)

-

Flatness/parallelism first: film thickness is microns—seat errors kill stiffness.

-

Supply interlocks: ensure pump/air supply is on and stable before motion; monitor pressure/flow.

-

Viscosity @ temperature: size for operating film; manage heat and de-aeration.

-

After coatings: re-measure IDs/ODs/flatness/grooves; verify lift-off speed and leakage.

Checklist

-

Seat flatness/parallelism verified

-

Supply pressure/flow interlocked & logged

-

Filtration & de-aeration validated

-

Post-coat metrology complete

Frequently Asked Questions

The wedge film forms only once there’s relative motion; select materials/coatings that tolerate brief rubs.

They can. Thickness and roughness shift film thickness, stiffness, and leakage. Measure geometry and validate lift-off after processing.

They can have high stiffness and low damping—address via design (tilting pads/squeeze film), supply stability, and structure.

Yes—validate materials/coatings for corrosion/biocompatibility, and control water chemistry.

Case Snapshots

- Precision rotary table chatter at low speed — Hydrostatic pads starved intermittently.

Actions: added accumulators, tightened pressure regulation, improved filtration; verified pad clearances post-coat.

Outcome: stiffer low-speed motion; reduced torque ripple. - High-speed blower bearing heat rise — Foil gas bearing showed start/stop scuffing.

Actions: introduced intake filtration, increased cool flow, applied wear-tolerant shaft surface; optimized ramp profile.

Outcome: start torque lowered; temperature stabilized.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).