Often, when the goal is bidirectional thrust in minimal space. For large overturning moments, keep a second bearing for stiffness.

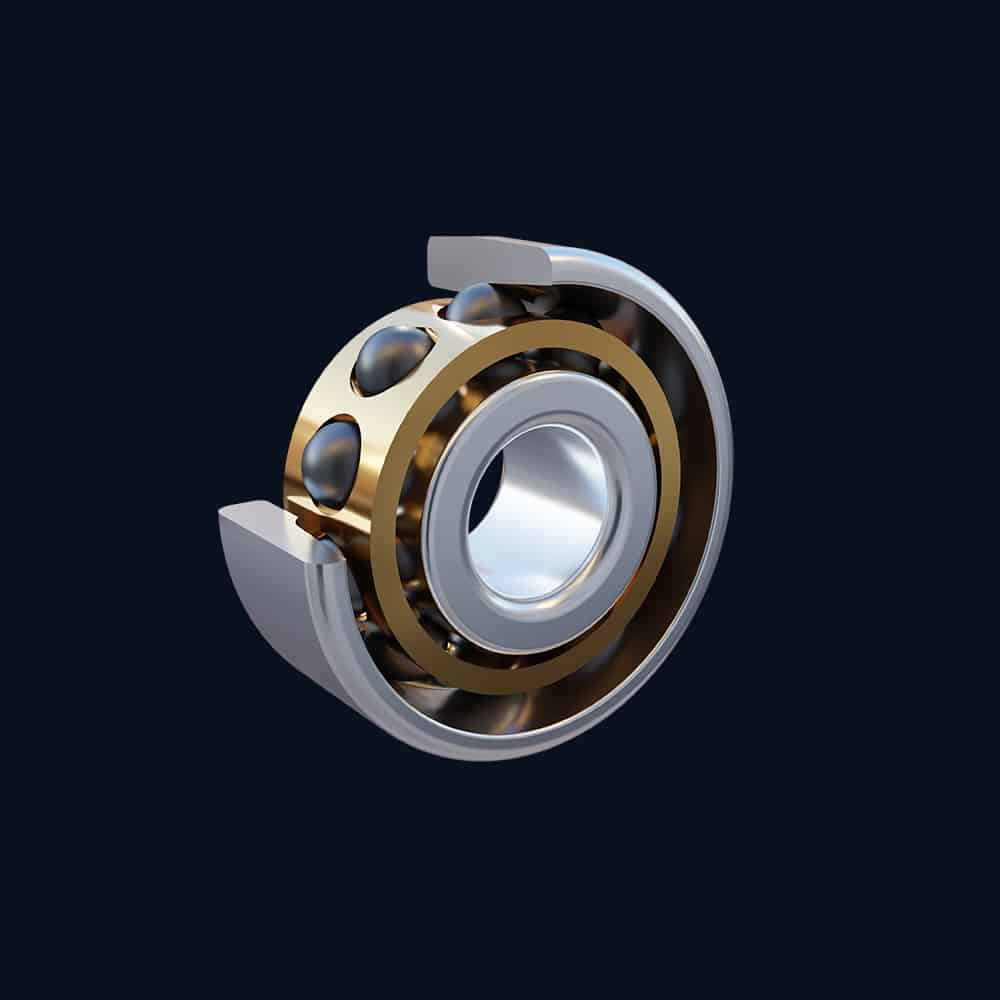

What Is a Four-Point Contact (QJ) Ball Bearing?

A single-row ball bearing with a large contact angle (≈35°) that can carry axial load in both directions plus radial load. QJ bearings are often used where a paired angular-contact set would normally be required, saving space and parts. They are not perfect moment bearings—pair with a second bearing when overturning moments are significant.

Typical uses: compact gearboxes, screw drives and actuators, turntables, compressors, light slewing rings, pumps, electric motor ends where bidirectional thrust is present.

Selection Cheatsheet (Load, Direction, Moment, Environment)

- Bidirectional thrust in limited space? QJ can replace an ACBB pair—confirm moment load is handled elsewhere.

- Moment present? Use a second bearing (radial or AC) spaced for overturning stiffness.

- Skidding risk? Avoid very light preload/clearance at high speed; ensure minimum radial load or preload.

- Environment: sealing/deflection first; choose lubricants for temperature and duty; treat surfaces when corrosion/fretting is the problem.

- After coatings: re-measure bore/OD/runout and **contact angle geometry**; small thickness changes can shift preload or seal gaps.

Environment → Attributes Matrix

| Environment | Material / Coating | Clearance / Preload | Fits (shaft / housing) | Sealing | Lubricant |

|---|---|---|---|---|---|

| Compact gearboxes | Through-hardened rings; optional wear/corrosion-resistant surfaces | Light preload or C0/C2; confirm no skidding | k5–m6 / H7; low runout seats | Shields or non-contact seals + gearbox sealing | Oil splash/jet per catalog viscosity @ temp |

| High speed (moderate thrust) | Low-roughness raceways; controlled thickness if coated | Light preload; maintain minimum radial load | Precision fits; balance and runout control | Low-drag shields/labyrinths | Low-bleed grease or oil (air-oil at very high dn) |

| Washdown / Food | Chromium-family or Ni-P (validated); stainless balls optional | C3 if interference/heat will reduce running clearance | k5–m6 / H7; verify post-coat geometry | Contact seals + deflectors; protect lips from jets | NSF H1 grease validated vs. cleaners & temp |

| Dusty / Abrasive | Hard, low-roughness surfaces; micro-textures optional | C3; avoid excessive drag from seals | Secure interference on rotating ring | Labyrinths + deflectors | Grease with sealing behavior; purge plan |

| Cleanroom / Vacuum | Clean, passivated surfaces; tight torque control | Light preload to keep torque low | Very low runout seats; minimal distortion | Non-contact shields; avoid elastomer outgassing | Low-outgassing grease or vacuum-rated oil |

Common Failures & Diagnostics

Rapid Triage

1) Misalignment / Edge Loading

Symptoms

Noise, heat, localized spalling near raceway edges.

Likely causes

Seat/runout errors, shaft/housing deflection, thermal distortion.

Checks

TIR/flatness; blue-check; thermal model; housing stiffness.

Non-coating actions

Improve flatness/parallelism; increase stiffness; correct alignment.

When surface treatments help

Secondary only—won’t fix geometry; can reduce scuffing once aligned.

2) Ball Skidding (light load, high speed)

Symptoms

Streaks/smearing; rising temperature; torque instability.

Likely causes

Insufficient preload/minimum radial load; low viscosity at temp.

Checks

Verify preload; calculate dn & viscosity @ operating temp; check cage.

Non-coating actions

Increase preload/min radial load; raise viscosity or move to oil/air-oil.

When surface treatments help

Low-roughness chrome can lower adhesion once film is adequate.

3) Preload Loss / Settlement

Symptoms

Backlash or axial float grows; noise on reversals.

Likely causes

Clamp relaxation; shim compression; thermal cycles.

Checks

Torque audit; axial play measurement hot vs. cold.

Non-coating actions

Re-set preload; improve clamp sequence; use harder shims.

When surface treatments help

May reduce seat fretting after clamp discipline is fixed.

4) Contamination / Abrasive Wear

Symptoms

Gritty feel, noise, accelerated wear.

Likely causes

Poor seals/deflectors; ingress during assembly; wash jets at seals.

Checks

Ingress routes; filter/cleanliness checks; seal lip condition.

Non-coating actions

Upgrade sealing/labyrinths; improve cleanliness; set purge/changes.

When surface treatments help

Hard chrome extends life after ingress is controlled.

5) Fretting / False Brinelling (idle vibration)

Symptoms

Reddish debris at seats; pitch-spaced dull marks; noisy start-ups.

Likely causes

Micro-motion with light preload; transport vibration; marginal film.

Checks

Transport profile; grease bleed; clamp integrity.

Non-coating actions

Stabilize transport; pick grease for idle vibration; confirm clamp.

When surface treatments help

Micro-textured chrome on seats reduces adhesion once motion is mitigated.

The Big Three: Corrosion, Lubricity, Dimensional Stability

Use coatings for surface-driven problems (corrosion, fretting, abrasion). They don’t replace correct fits, preload, or sealing.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Prevent rust/pitting at raceways and shoulders | Seals/deflectors; manage wash jets; compatible grease/oil; dry-out | Thin dense chrome, micro-cracked chrome, Ni-P (validated) | Re-measure clearance/contact angle geometry after processing |

| Lubricity | Stable film at large contact angle under bidirectional thrust | Viscosity @ temp; maintain minimum radial load/preload; avoid over-sealing drag | Low-roughness or micro-textured chrome reduces smearing/skid onset | Coatings complement—not replace—lube and preload discipline |

| Dimensional stability | Hold runout/parallelism; keep seal gaps and preload in spec | Flat seats, torque pattern, thermal model | Controlled-thickness coatings; post-coat metrology | Thin sections & split rings are thickness-sensitive |

Fits, Tolerances & Preload (Quick Rules)

-

Rotating ring gets light interference (k5–m6) to prevent creep; stationary ring H7 slip for serviceability.

-

Misalignment budget ≈ small: keep seats flat/parallel; control runout to bearing precision.

-

Set preload or ensure minimum radial load at speed to avoid skidding.

-

After coatings: re-measure ID/OD, runout, and contact angle geometry; confirm seal compression.

Checklist

-

Seat flatness/parallelism verified

-

Preload/min radial load checked cold & hot

-

Seal strategy consistent with speed & drag

-

Post-coat geometry/runout measured

Frequently Asked Questions

More sensitive than deep-groove; similar to AC bearings—keep seats flat and runout low to avoid edge loading.

As light as possible for torque/heat, but enough to prevent skidding at speed. Validate by torque and temperature trends.

They can shift clearance and seal compression if thickness isn’t controlled. Measure geometry before/after processing.

Shielded versions exist; most sealing is at the housing level (labyrinths/deflectors or contact seals).

Case Snapshots

- Compact gearbox, bidirectional thrust — Wanted to remove AC pair for space.

Actions: switched to QJ + separate radial bearing; set light preload; oil viscosity sized @ temp.

Outcome: package shortened; temperature stable; no reversal clunk. - High-speed actuator skidding — Torque spikes at speed, streaks on raceway.

Actions: added minimum radial load; raised viscosity grade; reduced seal drag.

Outcome: torque trace smoothed; lower operating temperature.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).