No. It is the free-end bearing and should see near-zero axial load. Provide a locating bearing elsewhere.

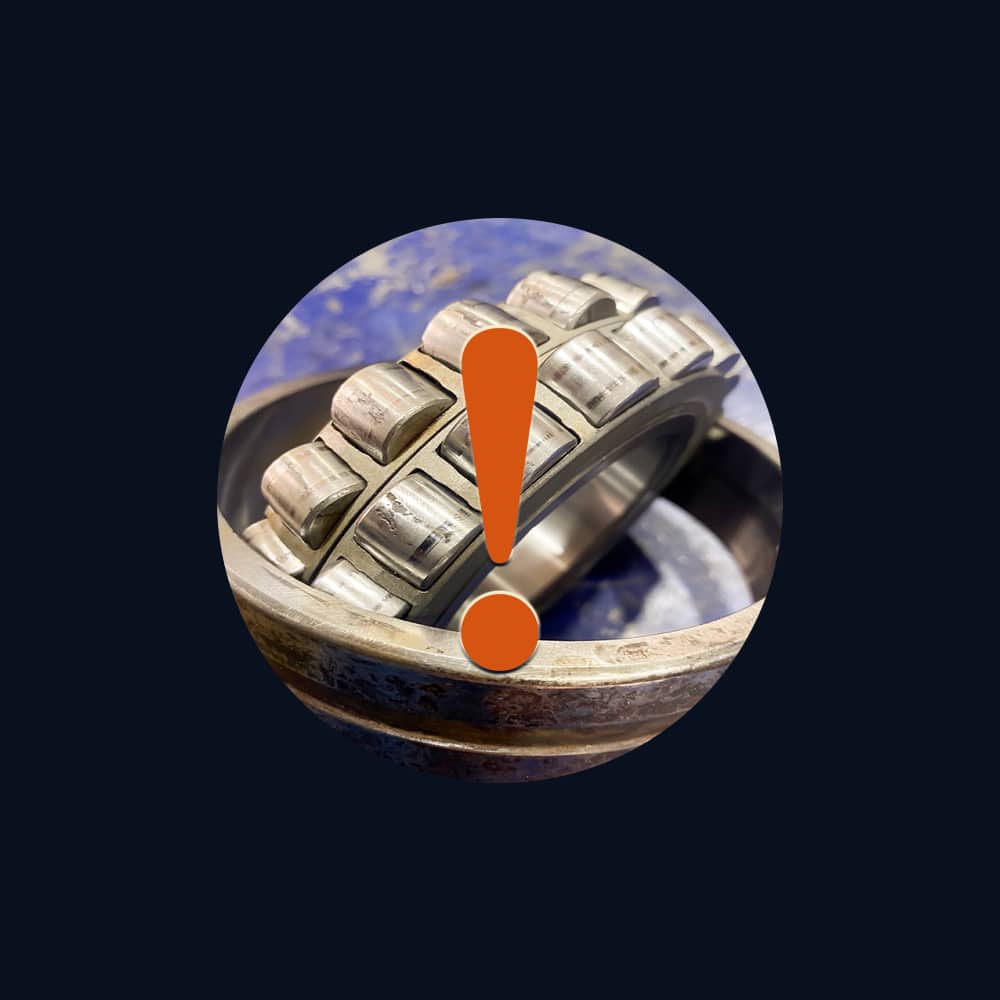

What Is a Toroidal Roller Bearing (CARB-type)?

A single-row roller bearing with toroidal raceway geometry that provides self-alignment and axial displacement (float) in one unit. It carries high radial load while letting the ring slide axially to absorb thermal growth. It is intended as the non-locating support—not for axial location or sustained axial load.

Typical uses: long shafts with thermal expansion (paper/steel mills, dryers), motors/generators, gearboxes and couplings where misalignment + float are needed, heavy industrial drives.

Selection Cheatsheet (Float, Alignment, Pairing, Environment)

- Use as the free end: CARB-type handles both misalignment and axial float—ideal where thermal growth is large.

- Pair correctly: Provide a locating bearing at the other support; do not try to “locate” with CARB.

- Respect limits: Verify allowable misalignment and total axial travel at operating temperature.

- Housing design: Seats must not block axial slide; avoid shoulders/clamps that trap a ring.

- Environment: Plan sealing/deflection; validate grease/oil chemistry (cleaners, moisture, dust).

- Surface treatments: Use for corrosion/fretting/abrasion; control thickness so float/clearance geometry remains in spec.

Environment → Attributes Matrix

| Environment | Material / Coating | Position / Function | Fits / Mounting | Sealing | Lubricant |

|---|---|---|---|---|---|

| Long shafts (motors/generators) | Low-roughness raceways; optional corrosion-resistant surfaces | CARB at free end; locating bearing on opposite end | Interference on rotating ring; seats free for axial slide | Labyrinths or shields | Grease or oil mist depending on speed/heat |

| Paper/steel mills (heat & misalignment) | Through-hardened surfaces; wear/corrosion-resistant coatings | Free end (float + alignment) | Robust shoulders; verify misalignment within limits | Deflectors + debris guards | Filtered circulating oil preferred for heat removal |

| Washdown / Food | Chromium-family or Ni-P (validated); tight thickness control | Free end; ensure float isn’t blocked by seals/shims | Check post-coat geometry; confirm axial travel | Contact seals + external deflectors; protect lips from jets | NSF H1 grease validated vs. cleaners & temp |

| Abrasive / Dusty | Hard, low-roughness surfaces; micro-textures optional | Free end; avoid axial trapping from shields/guards | Interference on rotating ring; shoulder geometry controlled | Labyrinths + deflectors; purge paths | Grease with sealing behavior; set purge intervals |

| High-speed, moderate load | Precision raceways; controlled cage | Free end; verify dn and heat rise | Alignment & runout controls to avoid edge contact | Low-drag shields or non-contact sealing | Low-bleed grease or oil (mist/air-oil) |

Common Failures & Diagnostics

Rapid Triage

1) Axial Float Blocked (trapped ring)

Symptoms

Rising temperature with thermal growth, axial marks at seats, noisy operation.

Likely causes

Shoulders/shims or seals clamp a ring; coating thickness reduced clearance; wrong locating scheme.

Checks

Confirm which end is locating; measure free axial travel cold/hot; inspect for mechanical stops.

Non-coating actions

Remove traps; redesign seats/seals; relocate locating function to the other end.

When surface treatments help

Not a primary fix—geometry/function first.

2) Misalignment Beyond Rating (edge contact)

Symptoms

Edge spalling on raceways, heat, reduced life.

Likely causes

Support deflection, bent shaft, housing distortion exceeds bearing limit.

Checks

Measure misalignment; blue check contact pattern; verify mounting rigidity.

Non-coating actions

Increase stiffness; reduce misalignment; ensure correct series selection.

When surface treatments help

Secondary—won’t correct geometry; can reduce scuffing once alignment is within limits.

3) Seat Creep / Micro-Slip

Symptoms

Polished bands or dark oxide at ring seats; positional drift.

Likely causes

Insufficient interference on rotating ring; vibration; thermal cycling.

Checks

Fits vs. catalog; surface finish; witness marks; temperature profile.

Non-coating actions

Increase interference; improve finishes; add mechanical locks.

When surface treatments help

Not a primary fix—address fit first.

4) Lubrication Starvation / Smearing

Symptoms

Smear marks, rising temperature, discoloration.

Likely causes

Viscosity too low at operating temp; grease channeling; high seal drag.

Checks

Viscosity index; relube interval; flow path to contact zone.

Non-coating actions

Increase viscosity or move to oil/air-oil; reduce drag; improve flow.

When surface treatments help

Low-roughness/micro-textured chrome can reduce scuffing once film is adequate.

5) Contamination / Abrasive Wear

Symptoms

Gritty feel, debris, accelerated wear.

Likely causes

Ingress via inadequate sealing/deflection; poor filtration; wash jets at seals.

Checks

Ingress routes; seal condition; filter analysis.

Non-coating actions

Upgrade sealing/labyrinths; improve filtration; purge plans.

When surface treatments help

Hard, low-roughness surfaces extend life once contamination is controlled.

Corrosion, Lubricity, Dimensional Stability

Apply coatings for surface-driven issues (corrosion, fretting, abrasion). Coatings don’t replace the correct free-end/locating scheme, float clearance, or alignment.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Protect raceways and seats from rust in wet/caustic service | Seals/deflectors; jet management; compatible grease; drying | Thin dense chrome, micro-cracked chrome, Ni-P (validated) | Re-measure geometry; confirm float isn’t reduced by thickness |

| Lubricity | Stable film under line contact and misalignment | Viscosity @ temp; adequate flow; minimize seal drag | Low-roughness or micro-textured chrome reduces smearing | Coatings complement—not replace—lubrication strategy |

| Dimensional stability | Maintain ID/OD/runout so misalignment & axial travel remain within limits | Verify free-end travel cold/hot; avoid axial traps; control fits | Controlled-thickness coatings; check after processing | Small thickness shifts can affect available float |

Fits, Seating & Float (Quick Rules)

-

Rotating ring = interference; stationary ring may be slip. Control finish and shoulder geometry.

-

Do not clamp axially: seats/seals must not trap the ring—preserve axial travel in both directions.

-

Pair with a locating bearing at the opposite end; CARB is the free-end only.

-

After coatings: re-measure bore/OD/runout; confirm axial travel and misalignment capacity remain within limits.

Frequently Asked Questions

Both self-align. CARB-type also allows axial displacement in the bearing, making it ideal as the non-locating support.

Thermal growth has nowhere to go → heat, edge loading, premature failure.

Most are open; sealing is typically done at the housing with labyrinths/deflectors.

They can. Control thickness and re-measure ID/OD/runout; verify axial travel after processing.

Case Snapshots

- Paper machine dryer section — Thermal bind at expansion end.

Actions: replaced CRB free-end with CARB-type; cleared axial traps; switched to circulating oil.

Outcome: temperature drop ~15 °C; alignment stabilized; fewer interventions. - Generator drive — Edge spalling from misalignment.

Actions: moved free end to CARB-type; verified misalignment within rating; added labyrinth seals.

Outcome: spalling eliminated; MTBF increased.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).