Not recommended. Use an inner ring or upgrade the shaft to a hardened, ground raceway spec.

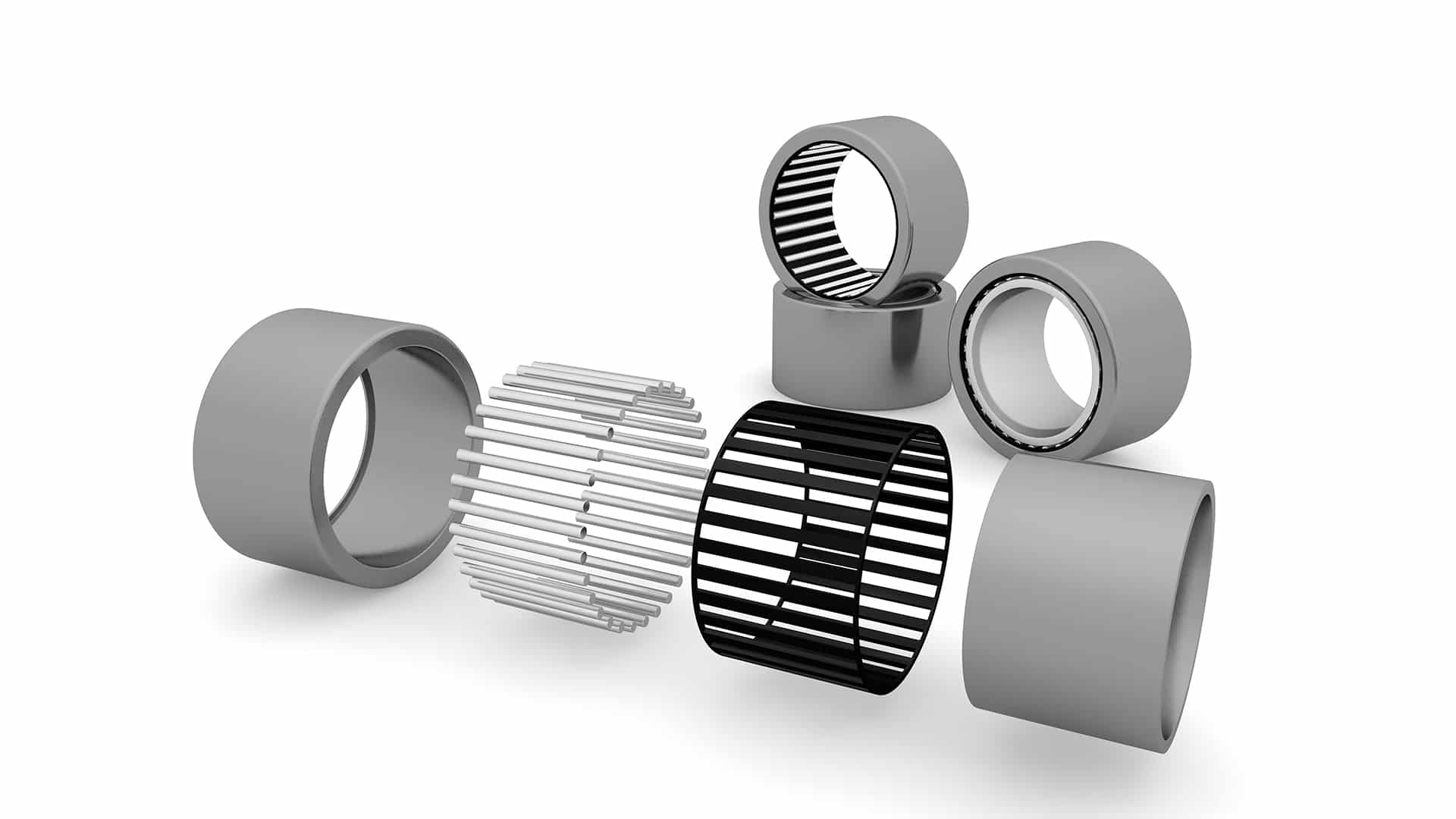

What Is a Needle Roller Bearing?

A compact radial bearing using many small-diameter rollers to achieve very high radial capacity per envelope. Offered as drawn-cup (thin-wall) and machined-ring (heavy-duty) types, with or without an inner ring (the shaft may serve as the inner raceway). Available in caged (higher speed) and full-complement (max capacity) designs.

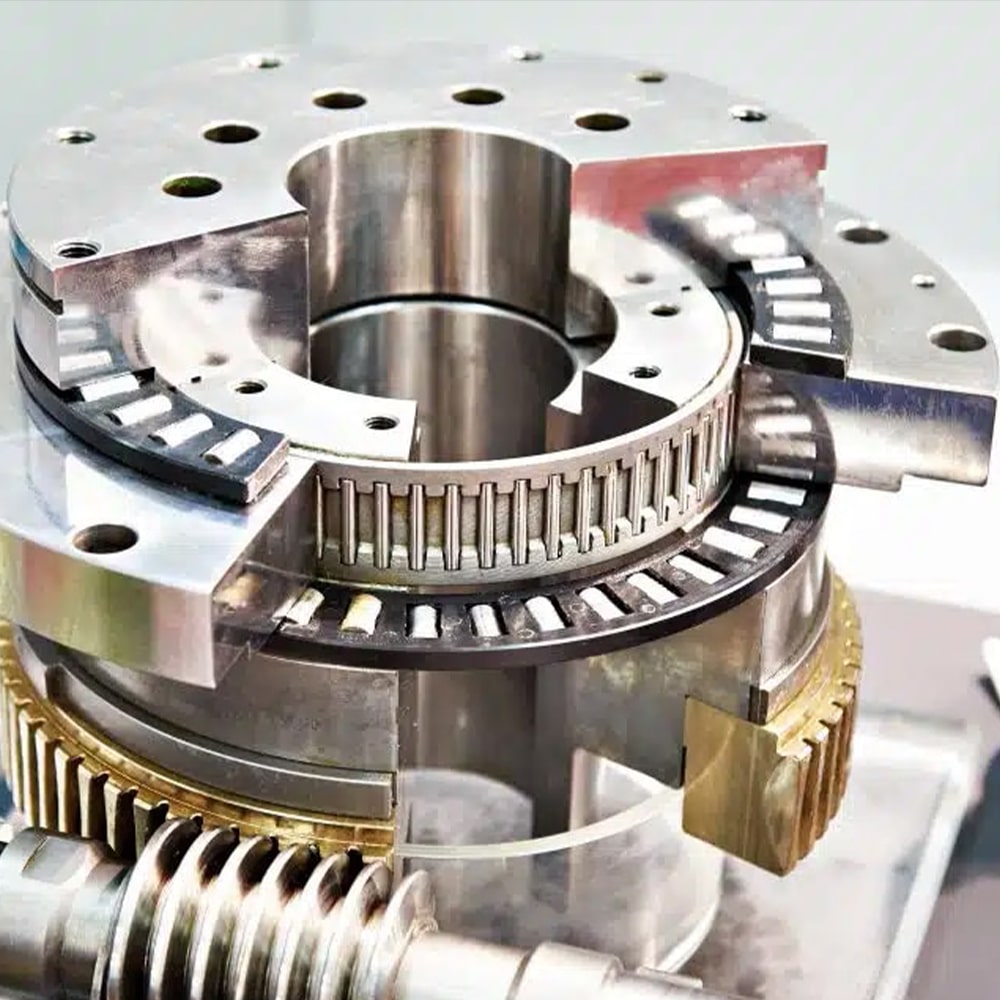

Typical uses: compact gearboxes, transmissions, pumps, small motors/tools, agricultural & construction equipment, appliance drives, and mechanisms with tight packaging.

Selection Cheatsheet (Raceway, Envelope, Environment)

- Inner ring vs. shaft raceway: choose an inner ring if the shaft can’t meet hardness/finish or service wear is expected.

- Drawn-cup vs. machined-ring: drawn-cup for tight envelopes/press-fit housings; machined-ring for higher stiffness & shock.

- Caged vs. full-complement: caged for speed/film formation; full-complement for max radial load at modest speed/oscillation.

- Axial loads? Pair with a thrust needle or use a separate axial bearing; radial NRB alone is not an axial solution.

- Environment: plan sealing/deflection and grease that survives wash, dust, or cleaners; validate chemistry.

- Surface treatments: apply to curb corrosion/fretting/abrasion; control thickness so ID/OD/roundness and clearance remain in spec.

Environment → Attributes Matrix

| Environment | Material / Coating | Type & Configuration | Fits / Mounting | Sealing | Lubricant |

|---|---|---|---|---|---|

| Washdown / Food | Chromium-family or Ni-P on rings/shafts; stainless options where offered | Caged drawn-cup with inner ring if shaft spec is marginal | Press-fit per catalog; verify ID after press & after coating | Contact seals + deflectors; avoid direct jets at lips | NSF H1 grease validated vs. cleaners & temperature |

| Abrasive / Dusty | Hard, low-roughness surfaces; coated shafts/rings for wear | Machined-ring or heavy-duty; full-complement if speed is modest | Robust housing; interference on rotating ring | Deflectors + labyrinths; purge paths | Grease with sealing behavior; scheduled purges |

| High-Speed / Continuous | Low-roughness raceways; controlled geometry | Caged type; inner ring for shaft protection | Precision shoulders; alignment control | Low-drag shields or non-contact sealing | Low-bleed grease or light oil feed; verify heat |

| Oscillation / Idle Vibration | Micro-textured hard chrome for fretting resistance | Caged preferred; full-complement only if speed is very low | Tight runout/roundness; avoid micro-motion at seats | Contact seals; isolate vibration during transport | Grease with film persistence; controlled relube |

| Compact / Thin Housing | Coatings with tight thickness control to protect ID | Drawn-cup; consider inner ring to protect shaft | Measure ID after press; support during pressing | External seals in housing; deflectors | Grease with good channeling; avoid overpack |

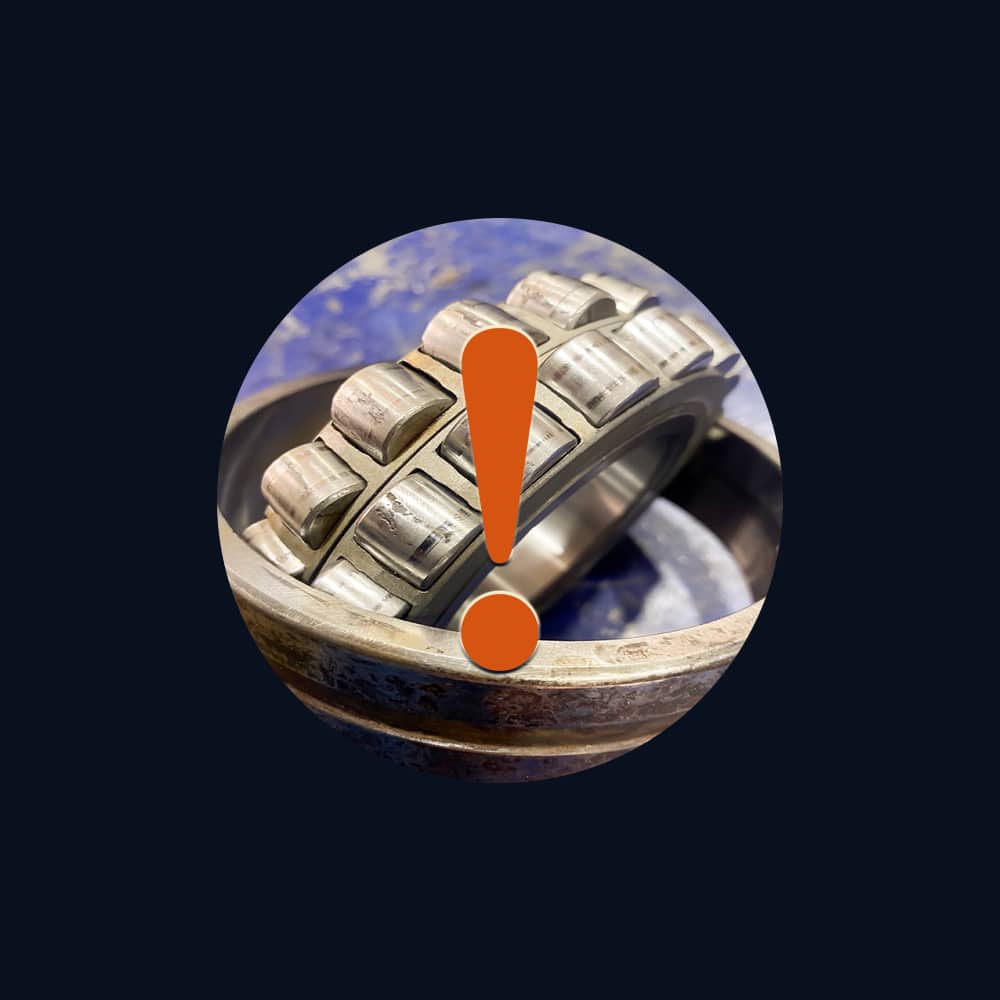

Common Failures & Diagnostics

Rapid Triage

1) Shaft Raceway Wear / Galling

Symptoms

Polished bands/transfer on the shaft, noise, rising torque.

Likely causes

Shaft too soft/rough; inadequate film; contamination; oscillation with low bleed grease.

Checks

Shaft hardness/finish vs. spec; lubricant grade at temperature; debris analysis.

Non-coating actions

Specify inner ring or upgrade shaft raceway spec; improve lubrication & sealing.

When surface treatments help

Hard, low-roughness chrome on shaft/inner ring once base spec is correct.

Won’t solve

Running on an unhardened shaft.

2) False Brinelling / Fretting (idle vibration)

Symptoms

Pitch-spaced dull dents, reddish/brown oxide, start-up roughness.

Likely causes

Micro-motion at rest; poor film persistence; transport vibration.

Checks

Idle vibration exposure; grease bleed/consistency; clamping/mounting micro-slip.

Non-coating actions

Stabilize transport; select grease with stronger film; adjust preload/seat to reduce micro-motion.

When surface treatments help

Micro-textured chrome resists adhesion and debris once motion/film are controlled.

Won’t solve

Large amplitude vibration or chronic under-lubrication.

3) Drawn-Cup Creep / Rotation in Housing

Symptoms

Shiny bands or black dust at the cup OD; positional drift.

Likely causes

Insufficient press-fit; thin wall housing; thermal cycles; poor bore finish.

Checks

Housing bore size/finish/roundness; press-fit vs. catalog; temperature profile.

Non-coating actions

Increase interference; improve bore finish; consider retaining features or switch to machined-ring.

When surface treatments help

Not a primary fix—address fit and housing stiffness first.

Won’t solve

Loose bores or oval housings.

4) Cage Wear / Skewing

Symptoms

Noise at speed, metallic debris, heat rise.

Likely causes

Insufficient lubrication at speed; misalignment; overload; full-complement used beyond speed limit.

Checks

Viscosity at temperature; speed vs. type (caged/full-complement); alignment.

Non-coating actions

Move to caged design; improve lubrication delivery; correct alignment/load.

When surface treatments help

Secondary—coatings won’t prevent cage starvation.

5) Contamination / Abrasive Wear

Symptoms

Gritty feel, debris in grease/oil, accelerated wear.

Likely causes

Ingress via inadequate sealing/deflection; filtration gaps; direct wash jets.

Checks

Ingress routes; seal lip condition; filter analysis; upstream guards.

Non-coating actions

Upgrade sealing/labyrinths; improve filtration; purge/change intervals.

When surface treatments help

Hard, low-roughness surfaces extend life once contamination is controlled.

Corrosion, Lubricity, Dimensional Stability

Use coatings where they address surface-driven issues (corrosion, fretting, abrasion). Coatings don’t replace correct fits, raceway specification, or sealing.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Prevent rust in tight ID/OD geometries and at raceways/seats | Seals/deflectors; jet management; compatible grease; drying | Thin dense chrome, micro-cracked chrome, Ni-P (validated) | Control thickness—small changes can tighten IDs |

| Lubricity | Film retention under oscillation/idle vibration | Grease selection for film persistence; avoid under-/over-pack | Low-roughness or micro-textured chrome reduces fretting/false brinelling | Coatings complement, not replace, lubrication strategy |

| Dimensional stability | Hold ID/OD/roundness after press/coating so running clearance stays correct | Measure after press; confirm shaft/housing geometry & hardness | Controlled-thickness coatings; verify post-process dimensions | Drawn-cup shells are sensitive to press-fit & ovality |

Fits, Tolerances & Clearance (Quick Rules)

- Drawn-cup: press-fit per catalog; support during pressing; measure ID and roundness after press.

- Shaft as raceway: hardened & ground with controlled finish and geometry; verify after any surface process.

- Inner ring option: use when shaft spec/hardness is marginal or where service wear is expected.

- After coatings: re-measure ID/OD/runout; small thickness changes can shift clearance significantly.

Frequently Asked Questions

When the shaft can’t meet hardness/finish, when service wear is expected, or for easier replacement/repair.

Press-fit ovality or coating thickness changed the effective ID. Measure after press and after any surface treatment.

Caged for speed and lubrication margin; full-complement for maximum radial capacity at modest speed.

Radial NRBs do not. Use a thrust needle bearing or another axial solution for axial loads.

Case Snapshots

- Compact gearbox — Fretting marks after idle storage.

Actions: switched to grease with better film persistence; added transport restraints; micro-textured chrome on inner ring.

Outcome: start-up roughness eliminated; longer idle intervals tolerated. - Washdown conveyor idler — Cup creep and early wear.

Actions: increased press-fit per catalog; added deflectors; selected H1 grease compatible with cleaners.

Outcome: creep dust disappeared; interval to first service doubled.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).