N or NU. They allow axial displacement of the shaft in both directions.

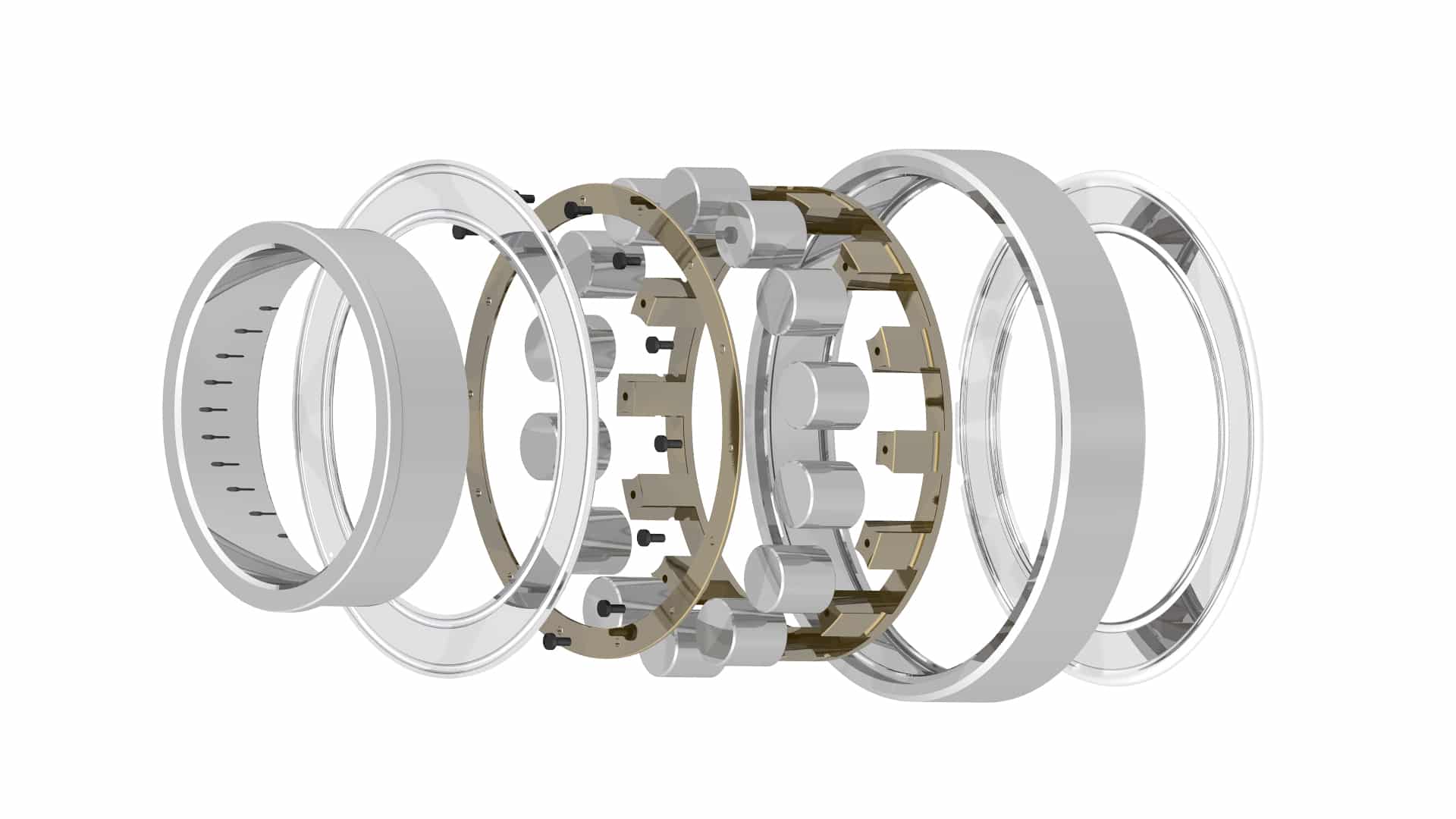

What Is a Cylindrical Roller Bearing?

A rolling bearing that uses cylindrical rollers in line contact with the raceways for very high radial capacity and low friction at speed. Axial capability depends on the rib (flange) arrangement—which also determines whether the bearing locates the shaft or acts as a free end (float) position.

Typical uses: motors & generators, pumps/gearboxes, machine tools, paper/steel mills, compressors, traction and heavy industrial drives.

Selection Cheatsheet (Locating vs. Free End, Ribs, Environment)

- Decide the support scheme first: one locating bearing, one free end bearing to absorb thermal growth.

- Free end (float): use N or NU so the shaft can move axially in both directions.

- Locating one direction: use NJ; add an HJ angle ring later if you need two-way location.

- Locating both directions (single bearing): use NUP (inner rib + loose rib ring).

- Environment: pick sealing/grease for contamination or wash; verify coating thickness if surfaces are treated.

- Speed vs. load: caged designs for speed; full-complement for very high radial load at modest speed.

Environment → Attributes Matrix

| Environment | Material / Coating | Type & Axial Scheme | Fits / Mounting | Sealing | Lubricant |

|---|---|---|---|---|---|

| Motors / Generators | Low-roughness raceways; optional corrosion-resistant surfaces | Locating: NJ or NUP; Free end: N or NU | Interference on rotating ring; alignment & shoulder control | Labyrinths; external seals as needed | Grease or oil mist per speed/size; check electrical grounding |

| Gearboxes / Oil Systems | Through-hardened or case-carburized; micro-textures optional | Locating: NJ/NUP; Free end: N/NU | Piloted shoulders; axial float verified at free end | Labyrinths + circulation seals | Circulating oil with viscosity sized for temp |

| Machine Tools (precision) | High precision classes; very low roughness | N/NU free end; NJ/NUP locating (minimal axial drag) | Squareness/parallelism critical; torque-controlled clamps | Non-contact seals to limit drag | Low-bleed grease or oil-air/oil-mist systems |

| Washdown / Caustic | Chromium-family or Ni-P; tight thickness control | N/NU for float; NJ/NUP to locate (verify post-coat geometry) | Protect seal paths from jets; confirm float isn’t constrained | Contact seals + deflectors; drain-friendly housings | NSF H1 grease validated vs. cleaners |

| High Radial Load / Moderate Speed | Full-complement possible; hard, low-roughness surfaces | N/NU for float; NJ/NUP to locate | Robust shoulders; alignment control to avoid edge loading | Deflectors & debris guards | Grease with EP/antiwear or filtered oil |

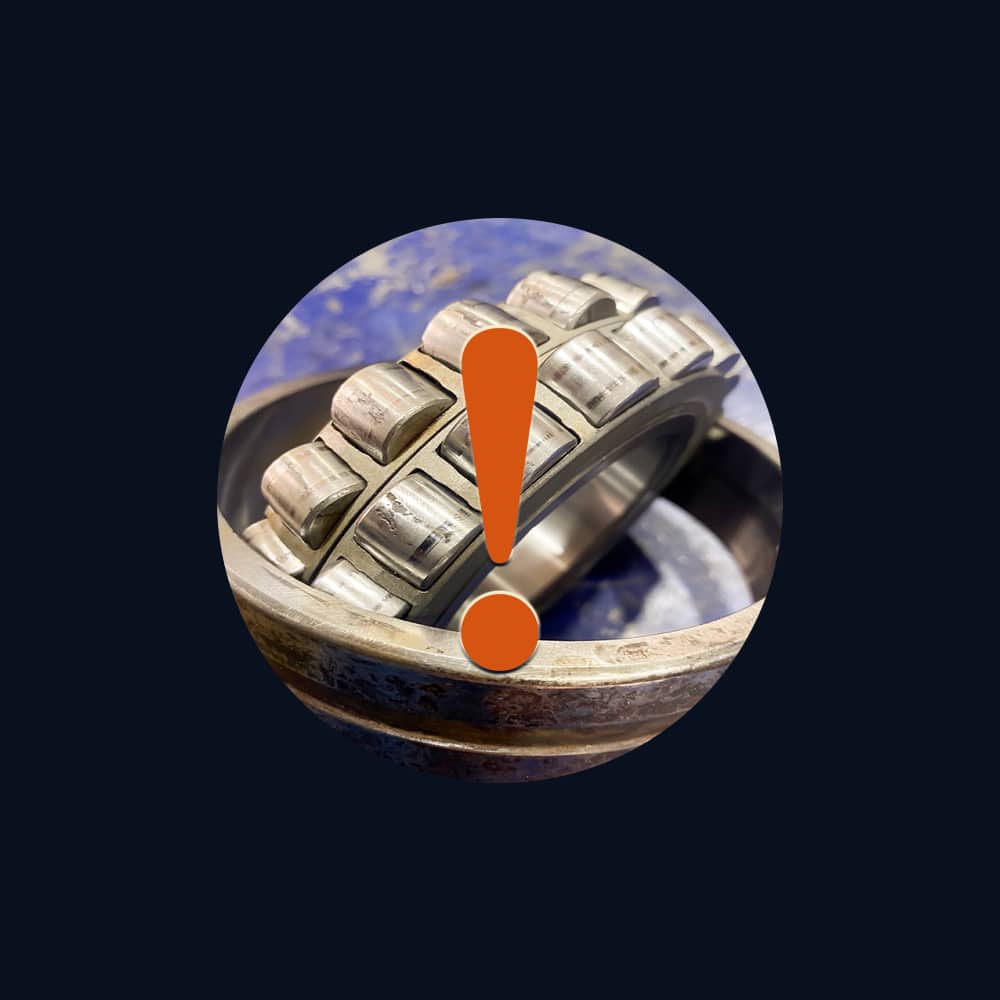

Common Failures & Diagnostics

Rapid Triage

1) Wrong Locating/Free-End Assignment

Symptoms

Thermal growth binds the shaft, rising heat/torque, axial drift marks.

Likely causes

Using NJ/NUP at both ends or blocking float on an N/NU free-end position.

Checks

Confirm rib types per end; inspect for endcap/shim interference; check axial play cold/hot.

Non-coating actions

Make one end free (N/NU); keep the other locating (NJ/NUP); re-verify hot condition.

When surface treatments help

Not applicable—this is a system layout issue.

2) Rib Face Scoring / Smearing

Symptoms

Darkened rib faces, metal transfer, temperature creep.

Likely causes

Low film strength at rib/roller guidance surfaces; viscosity too low; high speed with grease.

Checks

Operating temperature vs. viscosity; lubricant delivery; cage condition.

Non-coating actions

Increase viscosity index or switch to oil (circulation, jet, or mist); reduce drag from seals.

When surface treatments help

Low-roughness/micro-textured chrome can resist smearing once film is adequate.

3) Edge Loading / Misalignment

Symptoms

Local spalling at one raceway edge; noise and heat.

Likely causes

Housing/shaft misalignment; shoulder runout; bending under load.

Checks

Blue check of contact; shaft/housing alignment; face squareness.

Non-coating actions

Correct alignment; improve rigidity; verify shoulder geometry; avoid over-interference.

When surface treatments help

Coatings do not correct geometry—fix mechanics first.

4) Creep at Seats (micro-slip)

Symptoms

Polished bands/black oxide at ring seats; positional drift.

Likely causes

Insufficient interference on rotating ring; thermal cycling; poor finishes.

Checks

Fits vs. catalog; surface finish; witness marks; temperature profile.

Non-coating actions

Increase interference; improve finishes; add mechanical locks.

When surface treatments help

Not a primary fix—coatings won’t stop macro-movement from loose fits.

5) Contamination / Abrasive Wear

Symptoms

Gritty feel, debris in lube or filters, accelerated wear.

Likely causes

Ingress through inadequate seals/deflectors; poor filtration; washdown jets at seals.

Checks

Ingress routes; seal wear; filter analysis; upstream guards.

Non-coating actions

Upgrade sealing/labyrinths; improve filtration; purge plans after wash events.

When surface treatments help

Hard, low-roughness surfaces extend life once contamination is controlled.

Corrosion, Lubricity, Dimensional Stability

Use coatings for surface-driven issues (corrosion, fretting, abrasion). Don’t use coatings to compensate for the wrong rib type, misalignment, or incorrect free-end/locating scheme.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Prevent rust/chemical attack without blocking axial float paths | Right seals/deflectors; cleaner-compatible grease; dry after wash | Thin dense chrome, micro-cracked chrome, Ni-P—confirm thickness | Re-measure geometry/float after processing |

| Lubricity | Stable film at rib/roller guidance faces and raceways | Correct viscosity @ temp; adequate delivery; avoid seal over-drag | Low-roughness or micro-textured chrome to resist smearing | Coatings complement—not replace—lubrication strategy |

| Dimensional stability | Hold bore/OD/runout so locating/float behavior remains correct | Choose the right rib type; control fits; verify axial float at free end | Controlled-thickness coatings; verify after process | Full-complement amplifies sensitivity to misalignment |

Fits, Axial Location & Float (Quick Rules)

-

Rotating ring = interference; stationary ring may be slip. Verify finish and shoulder geometry.

-

Free end uses N/NU so the shaft can move axially. Ensure nothing clamps the floating ring.

-

Locating end uses NJ or NUP. NJ locates one direction; NUP locates both (or use NJ + HJ angle ring).

-

After coatings: re-measure bore/OD/runout; verify float and location still behave as designed.

Frequently Asked Questions

NJ locates in one direction; NUP locates both. An HJ angle ring can pair with NJ to locate both ways.

They carry more radial load but trade off speed and lubrication margin. Use only when speed is modest and lubrication is robust.

They can if thickness shifts geometry. Measure bore/OD/runout and confirm axial behavior after processing.

Case Snapshots

- Motor DE/NDE — Thermal bind after retrofit.

Actions: changed DE to NJ (locating), NDE to NU (free end); verified axial float hot.

Outcome: temperature normalized; axial marks eliminated. - Paper mill roll — Rib scoring at speed.

Actions: switched to circulating oil (higher viscosity @ temp); polished rib faces; added deflectors.

Outcome: smear resolved; longer service interval.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).