They self-align within catalog limits. Beyond that, edge loading accelerates wear—fix the structure or upsize.

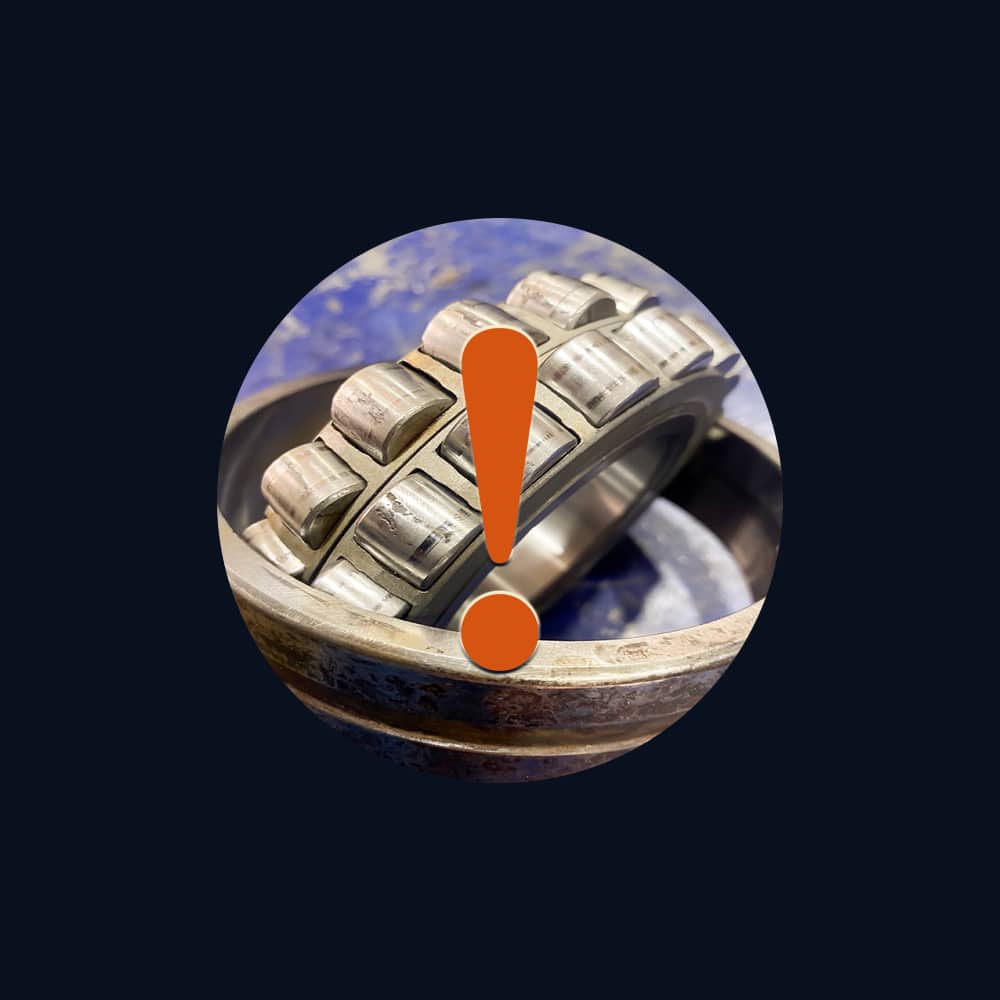

What Is a Spherical Roller Bearing?

A two-row barrel-roller bearing with a common spherical outer-ring raceway that self-aligns under shaft deflection or mounting error. It delivers very high radial capacity and moderate axial capacity (both directions), with strong tolerance to shock and misalignment.

Typical uses: bulk handling & conveyors, paper & steel mills, gearboxes, wind/industrial drives, fans/blowers, crushers, vibrating screens, heavy processing equipment.

Selection Cheatsheet (Misalignment, Capacity, Environment)

- Expect misalignment/shaft flex? SRB is designed for it—within catalog limits. Excess misalignment still reduces life.

- Axial load high? SRB carries moderate axial. For sustained/high axial, use tapered roller or thrust SRB.

- Tapered bore on sleeves simplifies interference setup via clearance reduction; record values during drive-up.

- Shock & contamination: SRB tolerates shock well; prioritize sealing/deflection and robust grease or filtered oil.

- Coatings mitigate corrosion/fretting/abrasion; confirm thickness so clearance/runout and seal gaps remain in spec.

Environment → Attributes Matrix

| Environment | Material / Coating | Clearance / Setting | Fits / Mounting | Sealing | Lubricant |

|---|---|---|---|---|---|

| Conveyors / Bulk Handling | Through-hardened rings; optional chrome-family for wear/corrosion | C3; check heat rise; adjust load zone | Rotating ring interference; sleeve drive-up documented | Labyrinths + deflectors | Grease with EP/antiwear; or filtered oil |

| Washdown / Caustic | Chromium-family or Ni-P; stainless cages where offered | C3; bias to lower torque with seals | Shield jets from seal paths; confirm post-coat geometry | Contact seals + external deflectors; drain-friendly housings | NSF H1 grease compatible with cleaners |

| Vibration / Shock (screens) | High-capacity designs; tough cages | C3/C4; verify operating clearance hot | Precision shoulders; sleeve lock hardware inspected | Heavy-duty deflectors; debris guards | Grease with film persistence under vibration |

| Gearboxes / Oil Systems | Low-roughness raceways; possible micro-textures | C3; target stable running clearance | Interference on rotating ring; alignment control | Labyrinths + circulation seals | Circulating oil with correct viscosity @ temp |

| High Temp / Heavy Duty | Heat-resistant cages; controlled-thickness coatings | C3/C4; re-check hot torque | Robust shoulders; sleeve drive-up logged | Low-drag shields or open + external seals | High-temp grease or oil feed |

Common Failures & Diagnostics

Rapid Triage

1) Edge Loading / Misalignment Beyond Limits

Symptoms

Heat at one side of the raceway, localized smearing, early spalling.

Likely causes

Structural misalignment exceeding bearing capability; distorted housings; poor foundation.

Checks

Measure misalignment; check housing squareness and stiffness; verify shaft deflection.

Non-coating actions

Restore alignment; stiffen mounts; re-select bearing size/series if persistent misalignment.

When surface treatments help

Only as polish against smearing once geometry is correct.

Won’t solve

Fundamental geometry/structure problems.

2) Clearance Lost After Mounting (sleeve drive-up)

Symptoms

Rising temperature, torque, dull “growl” shortly after startup.

Likely causes

Excessive drive-up on tapered sleeve; coating thickness not accounted; thermal contraction during cooldown.

Checks

Record initial radial internal clearance; measure reduction during drive-up; confirm post-coat dimensions.

Non-coating actions

Re-mount to spec’d clearance reduction; log torque/position; consider C3/C4 as needed.

When surface treatments help

N/A—this is a setting issue; coatings won’t fix lost clearance.

Won’t solve

Over-tight sleeves or wrong clearance class.

3) Smearing / Scuffing Under Shock or Poor Film

Symptoms

Gray patches, metal transfer, temperature spikes.

Likely causes

Viscosity too low at temperature; starved lubrication; severe shock.

Checks

Oil temp/viscosity; relube intervals; shock/impact events; cage condition.

Non-coating actions

Increase viscosity or switch to oil circulation; improve delivery; mitigate shock.

When surface treatments help

Low-roughness or micro-textured chrome can reduce scuffing once film is adequate.

Won’t solve

Chronic under-lubrication.

4) Contamination / Abrasive Wear

Symptoms

Gritty rotation, debris in grease/oil filters, accelerated race/roller wear.

Likely causes

Indirect sealing, missing deflectors, poor filtration.

Checks

Ingress points; seal wear; filter analysis; upstream guarding.

Non-coating actions

Upgrade seals/labyrinths; add deflectors; improve filtration and purge plans.

When surface treatments help

Hard chrome extends life once contamination is controlled.

Won’t solve

Open ingress or unfiltered fines.

5) Electrical Erosion (fluting)

Symptoms

Wave-like grooves, noise, premature grease darkening.

Likely causes

Stray currents through the bearing (VFD motors, grounding issues).

Checks

Shaft grounding/bypass paths; PWM/VFD settings; insulation continuity.

Non-coating actions

Install shaft grounding/insulated bearings; filters; cable practices.

When surface treatments help

Coatings aren’t a primary fix; use electrical insulation solutions.

Won’t solve

Active electrical discharge paths.

The Big Three: Corrosion, Lubricity, Dimensional Stability

Apply coatings for surface-driven issues (corrosion, fretting, abrasion). Don’t rely on coatings to compensate for poor fits, bad sleeve drive-up, or chronic misalignment beyond bearing limits.

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Rust/chemical attack at raceways/shoulders & seats | Seals/deflectors; jet management; compatible grease; dry-out | Thin dense chrome, micro-cracked chrome, Ni-P (validated) | Confirm chemistry & re-measure geometry after process |

| Lubricity | Stable film at high contact stress; low smearing under load | Right viscosity @ temp; adequate flow (oil) or relube plan (grease) | Low-roughness or micro-textured chrome supports film retention | Coatings complement—not replace—proper lubrication |

| Dimensional stability | Clearance remains correct after fits, heat, and processing | Control sleeve drive-up; measure clearance reduction; thermal model | Controlled-thickness coatings; verify post-coat clearance/runout | Record cold/hot clearance to avoid surprise preload |

Case Snapshots

- Vibrating screen — Smearing & heat after relines.

Actions: switched to high-capacity SRB, increased grease base viscosity, added deflectors.

Outcome: 20–25% temperature drop; smear marks ceased. - Caustic wash conveyor — Corrosion & noise at seals.

Actions: sealed SRB with external deflectors, H1 grease compatible with cleaners, chromium-family ring coating.

Outcome: >2× interval to first service; quieter post-wash.

Frequently Asked Questions

Often yes. Account for added drag; choose viscosity accordingly and verify hot running clearance.

No. Coatings add margin against corrosion/fretting, but ingress control (seals/deflectors) is fundamental.

Revisit sleeve drive-up and clearance class. Over-drive is common—measure and document reduction during install.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).