Only limited axial capability. For substantial thrust, consider angular-contact or tapered roller bearings.

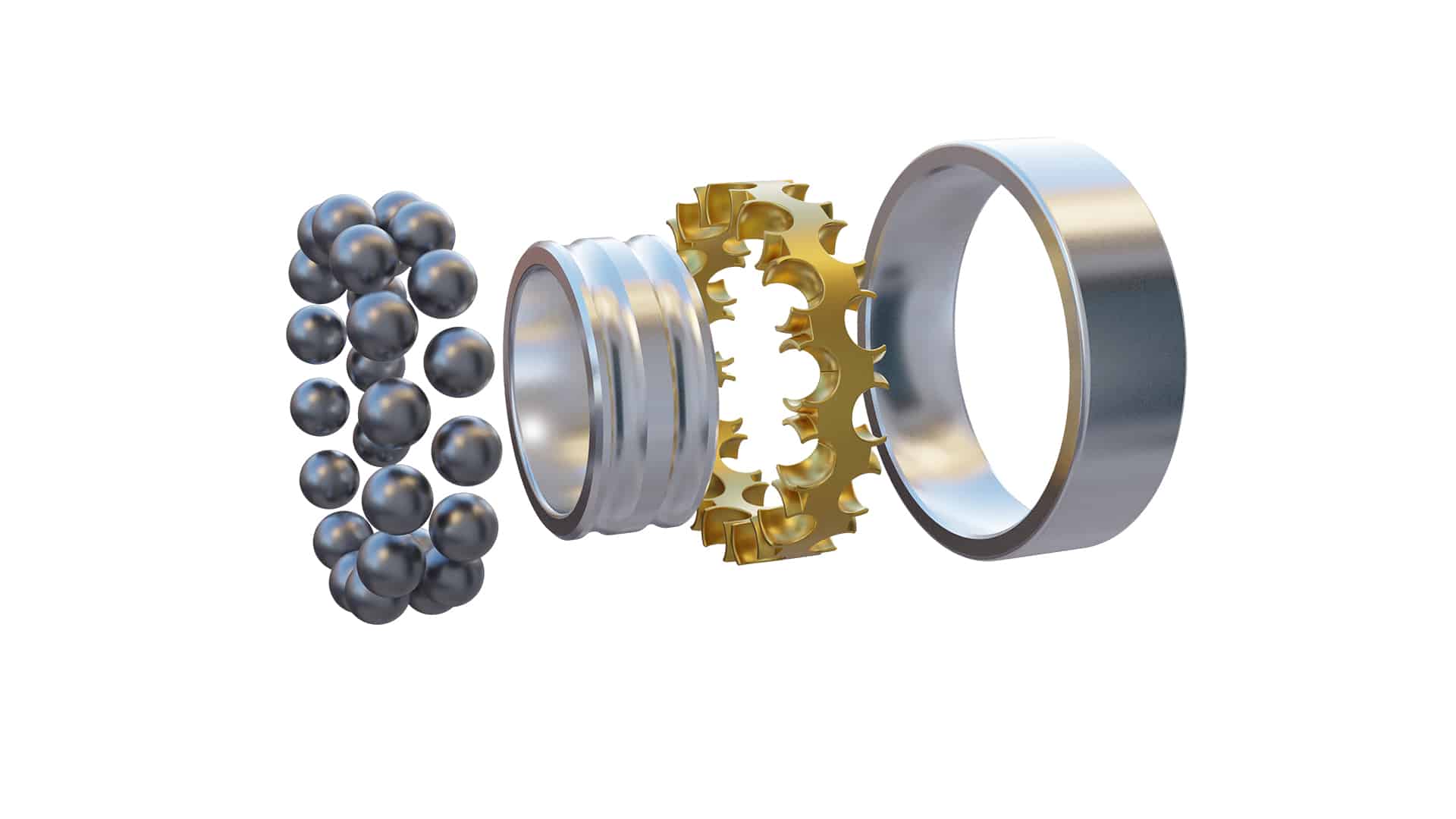

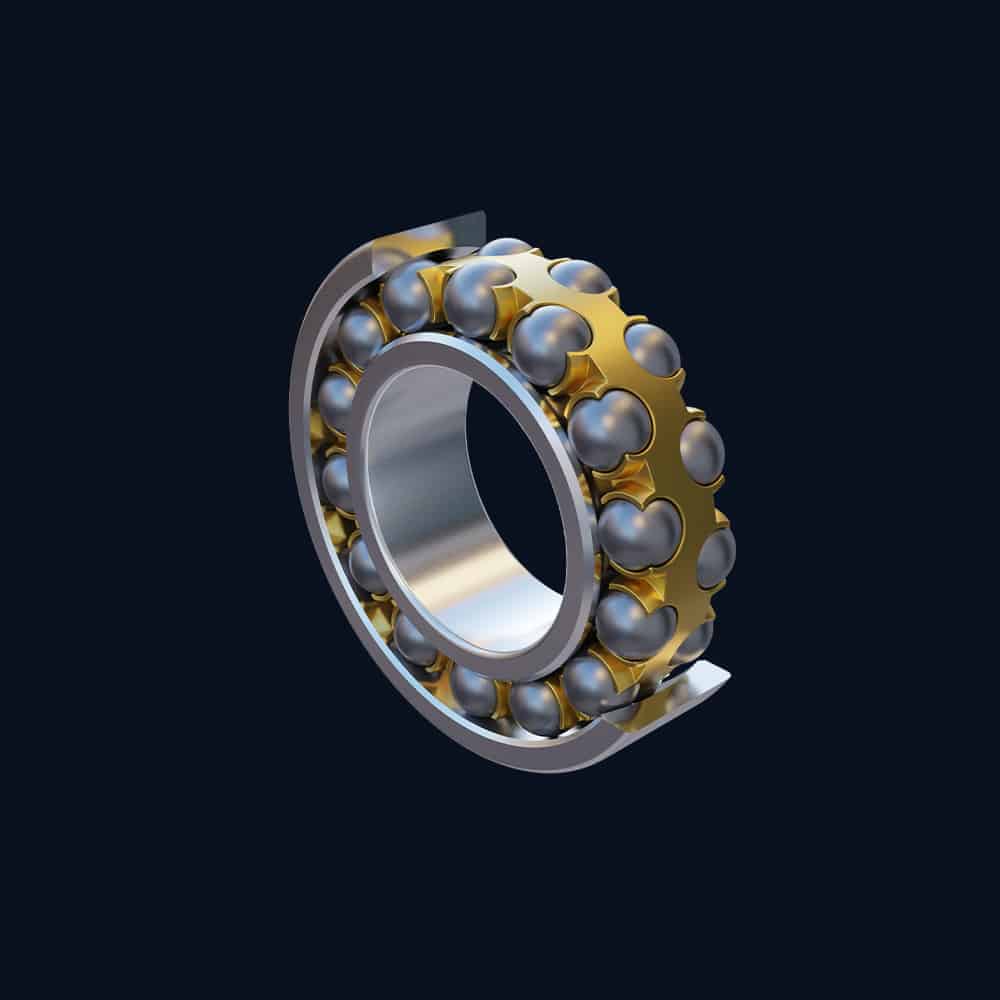

What Is a Self-Aligning Ball Bearing?

A double-row ball bearing with a spherical outer-ring raceway that allows the inner ring/shaft to run at an angle relative to the housing. Primarily supports radial loads with limited axial capacity in both directions, while tolerating shaft deflection or mounting misalignment.

Typical uses: long shafts with deflection, belt-driven equipment, fans/blowers, conveyors, agricultural machinery, and housed units where alignment is difficult.

Selection Cheatsheet (Load & Alignment)

- Misalignment unavoidable (mounting tolerance, shaft deflection): choose self-aligning ball bearings and verify the series’ rated misalignment angle.

- Radial load dominant; axial limited: SABB is appropriate. For substantial axial load, move to angular-contact or tapered roller.

- Long shafts / belt drives: favor housed units with spherical seats to preserve the self-aligning function.

- Space/weight constrained: choose a narrower series; confirm stiffness and seal options.

- Harsh washdown/caustic: contact seals + deflectors, cleaner-compatible H1 grease, and corrosion-resistant surfaces.

Environment → Attributes Matrix

| Environment | Material / Coating | Clearance | Fit (shaft / housing)* | Sealing | Lubricant |

|---|---|---|---|---|---|

| Washdown / Food | Stainless or coated rings; stainless/ceramic balls | C3 (to absorb interference & thermal) | k5–m6 / H7; ensure spherical seat can move | 2RS + deflectors; protect seal lips from jets | NSF H1 grease validated vs. cleaners/temps |

| Abrasive / Dusty | Coated rings; hard, low-roughness surfaces | C3 | k5–m6 / H7; add slingers/labyrinths | 2RS or shield + labyrinth | Grease with strong sealing behavior |

| Cleanroom / Vacuum | Clean, passivated steel; controlled surfaces | Per thermal model | Controlled interference to prevent creep | Non-contact shields or labyrinths | Low-outgassing oils/greases (minimal volatility) |

| High-Speed (moderate axial) | Through-hardened steel; consider hybrid balls | C0–C3 (match heat & speed) | Precision fits; verify dn and heat rise | Shields or low-drag seals | Low-bleed grease or oil per catalog |

| High-Temp Wash / Caustic | Coated rings (chromium or Ni-P); stainless balls | C3 | k5–m6 / H7; check post-wash drying | 2RS + external deflectors | H1 grease with cleaner & heat compatibility |

*Assumes rotating inner ring; adjust for your kinematics.

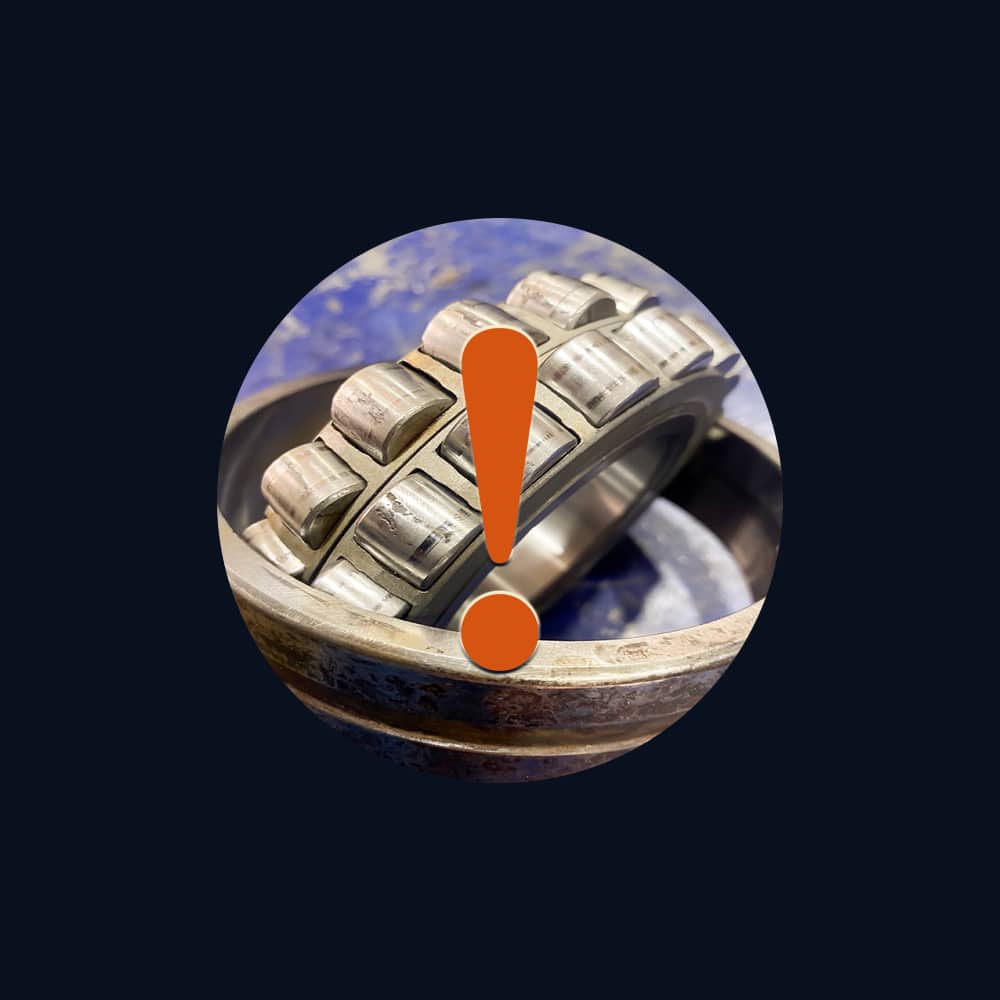

Common Failures & Diagnostics

Rapid Triage

1) Corrosion (pitting/crevice/rust staining)

Symptoms

Brown/red staining near seals, rough running, elevated noise after washdown cycles.

Likely causes

Water/chemical ingress; inadequate post-wash drying; cleaner pH/chemistry attacking steel; marginal grease film.

Checks

Seal condition and contact; ingress paths (shaft shoulders, housings); cleaner MSDS/compatibility; water jets aimed at seals.

Non-coating actions

Improve sealing (contact + deflectors), adjust washdown angles/pressures, select compatible H1 grease, add purge routine, consider stainless rings/balls.

When surface treatments help

Hard, inert chromium-family or electroless nickel surfaces that resist corrosion initiation and crevice attack at raceways/shoulders.

Won’t solve

Chronic misalignment, loose fits that pump fluid in, underspecified seals.

2) Fretting / False Brinelling

Symptoms

Evenly spaced dents at ball pitch, reddish/black oxide, start-up roughness after idle or transport.

Likely causes

Vibration at rest; micro-slip from loose fits; inadequate lubricant film persistence.

Checks

Fits (shaft/housing), vibration levels during transport/standby, preload (if applicable), grease bleed/retention.

Non-coating actions

Tighten fits or add locking features; transportation locks or isolation; select grease with better film retention; minimize idle vibration.

When surface treatments help

Micro-textured hard chrome can reduce adhesive onset and oxide debris generation after root causes are controlled.

Won’t solve

Persistent large-angle oscillation, structural misalignment, or grossly loose fits.

3) Edge Stress / Spalling (misalignment beyond rating)

Symptoms

Elevated heat and noise; localized raceway edge damage; shortened life despite “self-aligning” design.

Likely causes

Misalignment angle exceeds catalog limit; spherical seat/housing constrains bearing’s self-alignment; bent shaft.

Checks

Measure installed misalignment vs. rated angle; inspect spherical seat freedom and housing geometry; check shaft straightness.

Non-coating actions

Restore self-aligning freedom (proper seat, clearance); reduce misalignment by correcting mounting or shaft deflection; consider a series with higher misalignment tolerance.

When surface treatments help

Not applicable as a primary fix—address geometry and alignment first.

Won’t solve

Any geometry/alignment error that pushes contact to raceway edges.

4) Abrasive Wear / Contamination

Symptoms

Gritty sound, rising torque, particulate in grease, accelerated seal wear.

Likely causes

Ingress of dust/slurry; ineffective sealing; lack of slingers or labyrinths; poor upstream filtration.

Checks

Ingress points (seal lips, shaft shoulders), seal wear patterns, presence of fines in grease, upstream shielding/filtration.

Non-coating actions

Upgrade sealing (2RS + slingers/deflectors), add labyrinths, improve filtration, implement purge relube intervals.

When surface treatments help

Hard, low-roughness surfaces can reduce cutting and extend life when paired with better sealing.

Won’t solve

Open ingress paths or chronic contamination sources.

5) Creep at Seats (ring micro-movement)

Symptoms

Polished or darkened (oxide) bands at seat interfaces; positional drift; black dust near joint.

Likely causes

Insufficient interference fit; thermal cycling; inadequate clamping of spherical seat components.

Checks

Verify shaft/housing tolerances; inspect witness marks; confirm seat clamping torque and component flatness.

Non-coating actions

Increase interference or add mechanical locks; correct tolerances; ensure spherical seat is properly retained yet free to align.

When surface treatments help

Generally not a substitute for proper fits; surface changes won’t prevent macro-movement.

Won’t solve

Loose fits, poor seat retention, or thermal growth mismatch.

The Big Three: Corrosion; Lubricity; Dimensional Stability

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

|---|---|---|---|---|

| Corrosion resistance | Rust/crevice/chemical attack in target environment | Sealing strategy, jet angle, drying, cleaner-compatible grease | Thin dense chrome (nodular), microcracked chrome | Validate food/biocompatibility where applicable; check cleaner pH |

| Lubricity | Low friction & film retention under vibration/oscillation | Correct clearance; prevent seat binding; grease selection/relube | Micro-textured hard chrome can resist fretting/false brinelling | Coatings complement, not replace, proper fits and alignment |

| Dimensional stability | No detrimental change to geometry/clearances or seal gaps | Confirm fits & spherical seat freedom; thermal model | Controlled-thickness coatings; verify post-coat runout & seal gaps | Thin sections are sensitive—tight thickness control |

Case Snapshots

- Fan assembly with shaft deflection — Edge spalling after alignment attempts.

Actions: switched to SABB with true spherical seat, added deflectors, cleaner-compatible H1 grease.

Outcome: torque stabilized; inspection at 6 months showed no edge stress. - Conveyor idler (washdown) — Rust staining and roughness after 8 weeks.

Actions: 2RS seals + slingers, rinse/dry protocol, coated rings for corrosion resistance.

Outcome: service interval extended to 24+ weeks between checks.

Frequently Asked Questions

No. Coatings mitigate surface-driven issues (corrosion, fretting, abrasion). Misalignment must be addressed by design and correct seating.

Often not. You still need proper sealing/deflectors, cleaner-compatible H1 grease, and good rinse/dry practices.

They add drag, but in direct spray zones protection outranks torque. Choose grease accordingly and consider external deflectors.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).